An outer corridor shunting cab rear cabin integrated device

The technology of a driver's cab and a rear engine room is applied in the field of the integrated device of the rear engine room of the shunting driver's cab in the outer corridor, which can solve the problems of irregular electrical wiring, limited locomotive space, difficult operation, etc., so as to facilitate hoisting and maintenance, and reduce costs. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

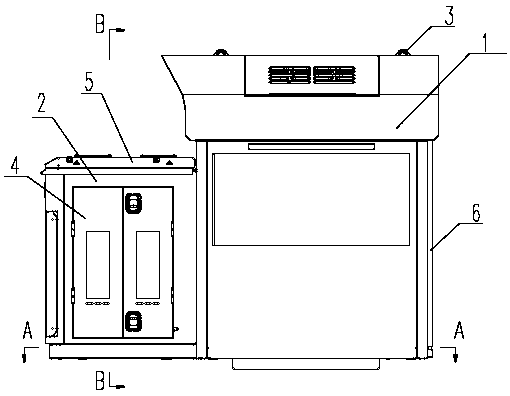

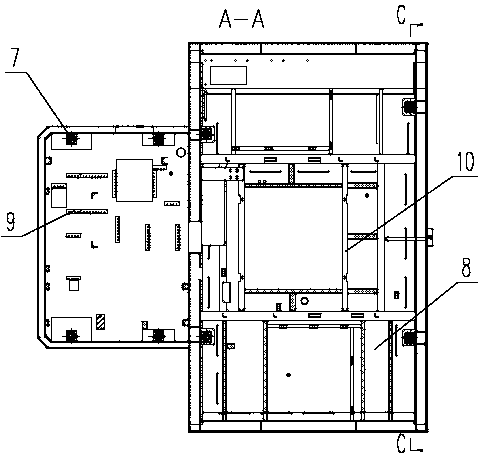

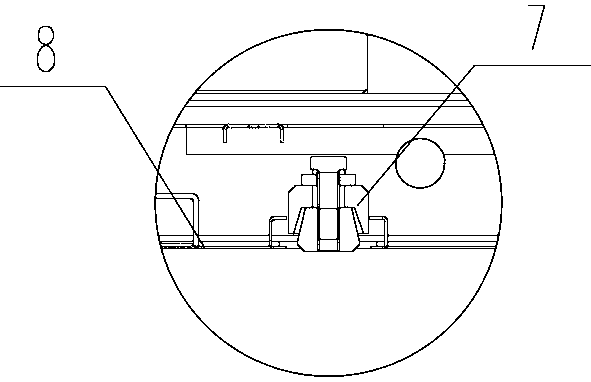

[0021] The present invention proposes an integrated device behind the shunting driver's cab in the outer corridor, such as figure 1 and figure 2 As shown, it includes the driver's cab 1 and the rear machine room 2. The driver's cab 1 and the rear machine room 2 form a whole by welding, and are connected to the locomotive frame through the mounting seat 7 at the bottom of the driver's cab 1 and the rear machine room 2. Specifically : the top of the driver's cab 1 is provided with a suspension ring 3, the inside is provided with a movable floor beam 10, and the outside is provided with an air-conditioning centralized drain pipe 6. The air-conditioning condensed water at the top of the driver's cab 1 is discharged to the vehicle f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com