Brick stacking machine and brick production system

A brick stacking machine and brick clamping technology, which is applied to conveyor objects, stacking of objects, destacking of objects, etc., can solve the problems of complex operation of the brick stacking machine, and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

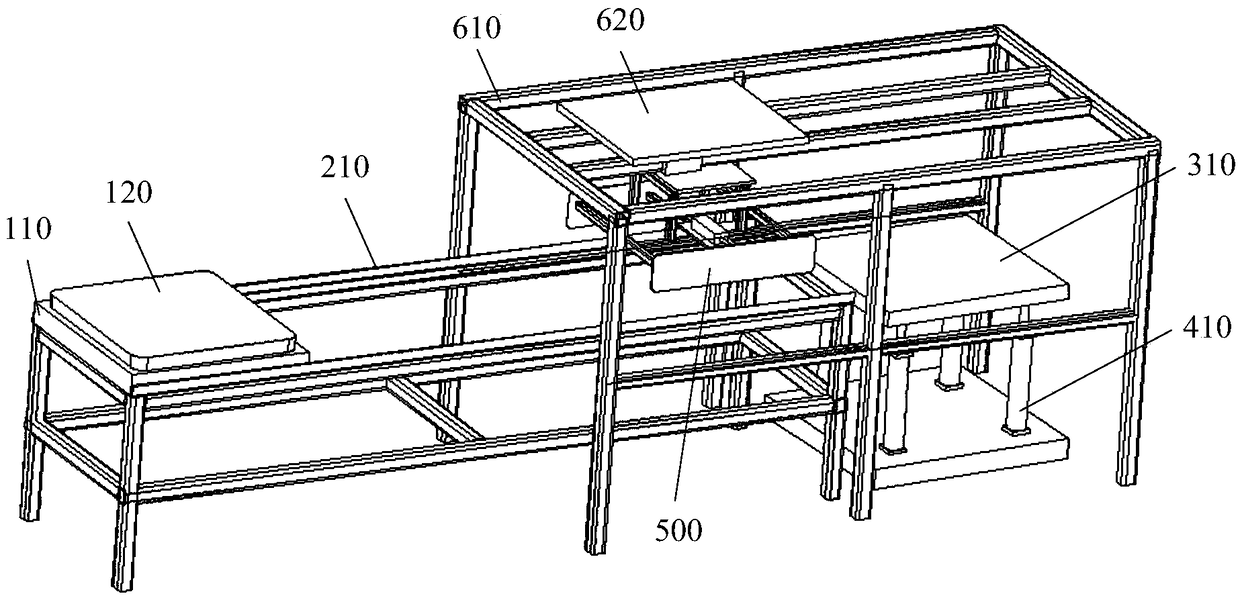

[0033] Such as figure 1 As shown, the stacking brick machine provided by the embodiment of the present invention includes: a feeding support mechanism, a feeding conveying mechanism, a material receiving mechanism, a material receiving lifting mechanism, a brick clamping mechanism 500 and a brick clamping conveying mechanism, the feeding conveying mechanism and the feeding material The supporting mechanism is connected by transmission, and the feeding conveying mechanism is used to drive the feeding supporting mechanism to move towards or away from the brick clamping mechanism 500;

[0034] The material receiving lifting mechanism is connected with the material receiving mechanism by transmission, and the material receiving lifting mechanism is used to drive the material receiving mechanism to rise or fall in the vertical direction;

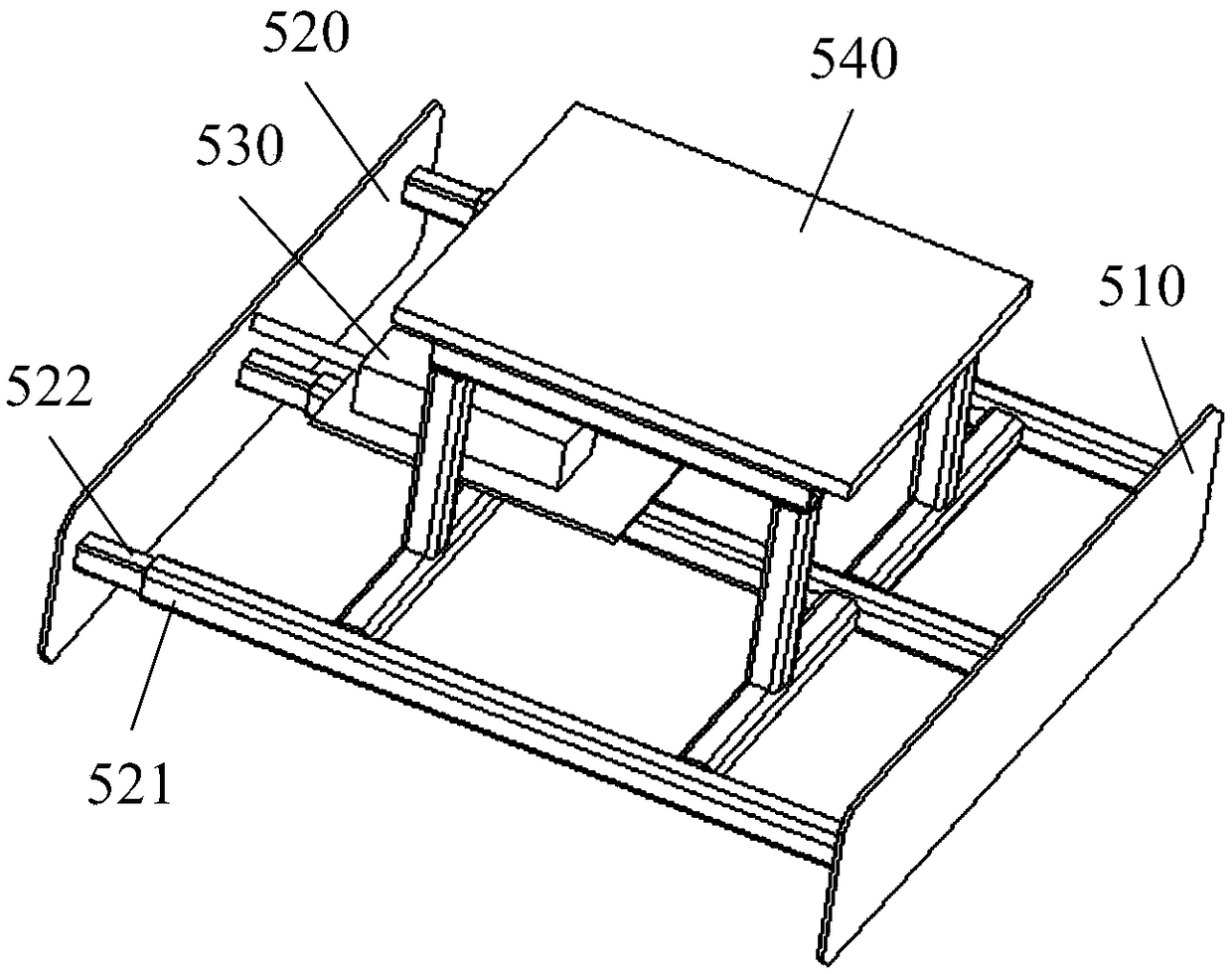

[0035] The brick clamping conveying mechanism is in transmission connection with the brick clamping mechanism 500, and the brick clamping convey...

Embodiment 2

[0064] The second aspect of the embodiment of the present invention provides a brick production system to alleviate the technical problem of complex operation of brick stacking machines in the related art.

[0065] The brick production system provided by the embodiment of the present invention includes the brick stacking machine mentioned above.

[0066] The brick production system provided by the embodiment of the present invention also includes a material receiving device, which includes a material receiving and pushing mechanism and a material receiving and conveying mechanism. The bricks on the pallet are pushed to the receiving and conveying mechanism, and the receiving and conveying mechanism will transport the stacked bricks to the designated position.

[0067] The brick production system provided by the embodiment of the present invention has the same advantages as the brick stacking machine compared with the related technology, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap