A cotton wool plush cleaning unit

A cotton silk and plush technology is applied in the field of cotton plush cleaning unit, which can solve problems such as lack of finishing equipment, and achieve the effect of avoiding roughness and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

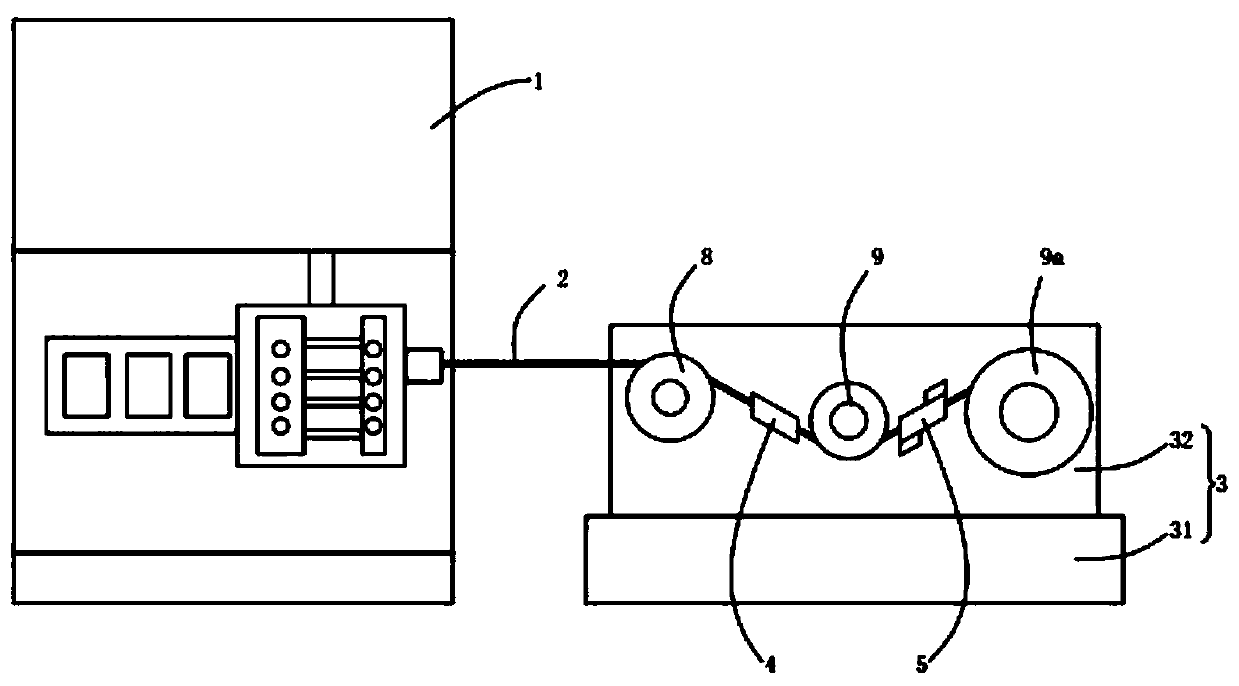

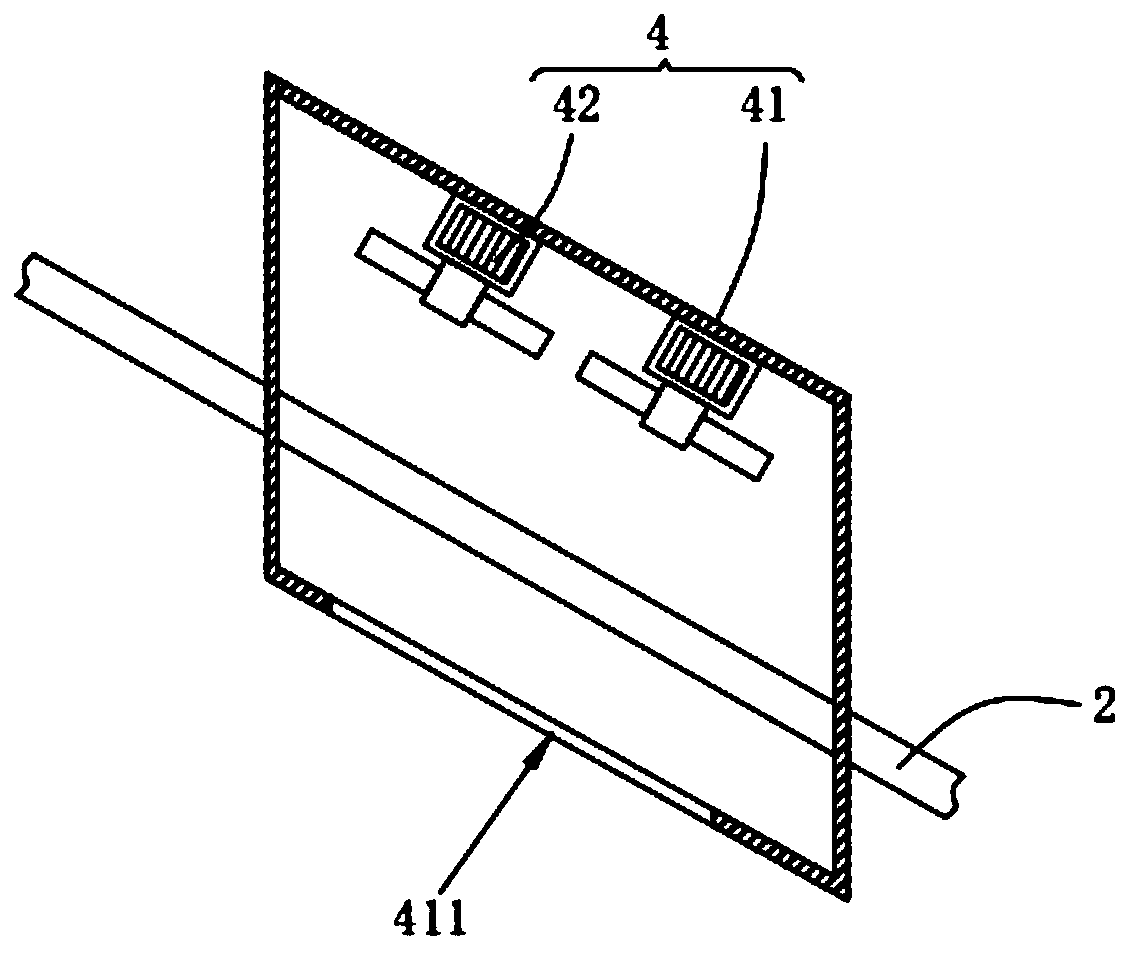

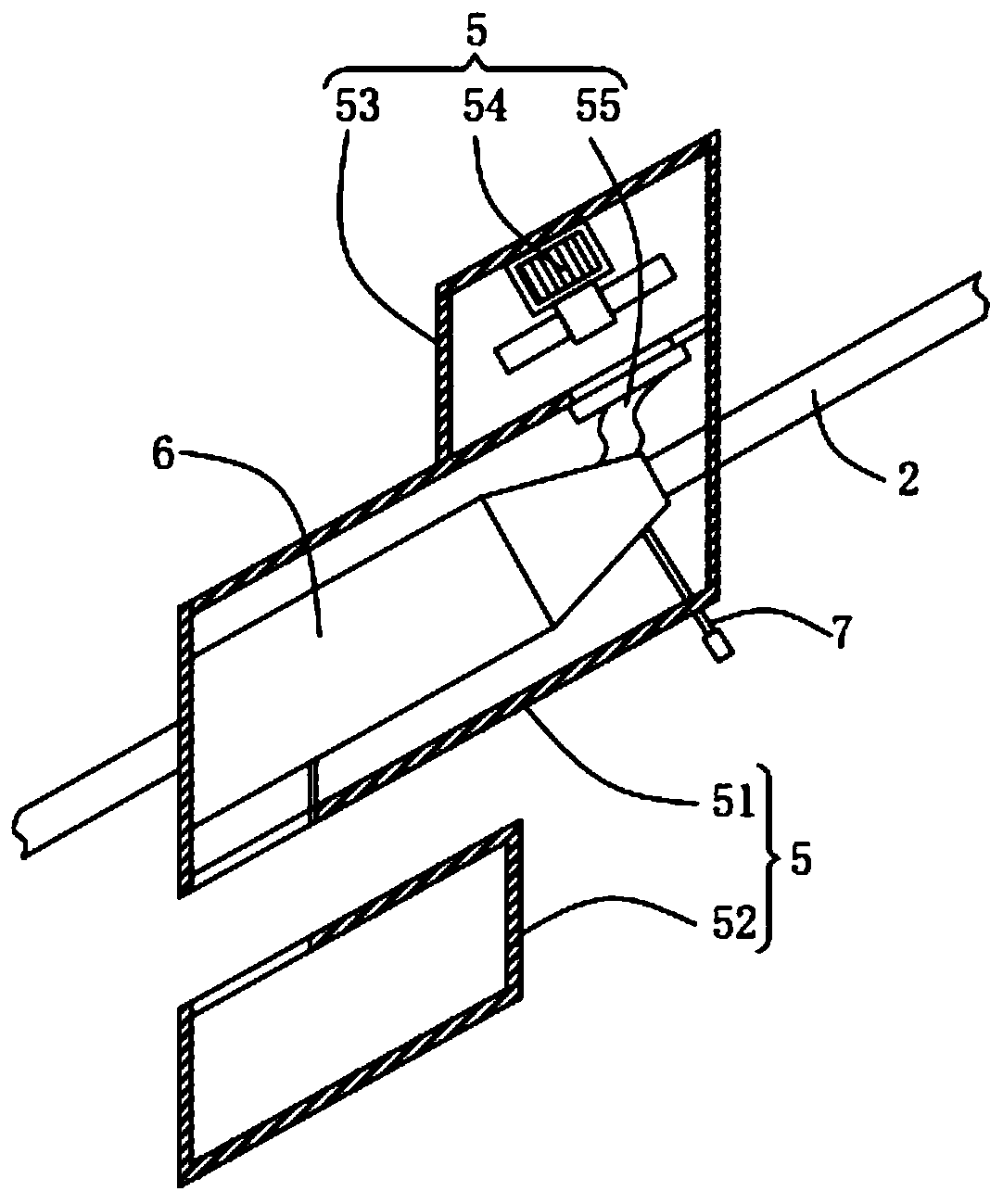

[0023] Such as Figure 1-Figure 6 As shown, a wool cleaning unit for cotton yarn according to the present invention includes a spinning machine body 1, cotton yarn 2, a support mechanism 3, a first guide wheel 8, a second guide wheel 9 and a winding wheel 9a, It also includes a cooling mechanism 4, a processing mechanism 5, a separation pipe 6 and a clamping mechanism 7; the inside of the cooling mechanism 4 runs through the cotton filament 2, and the cooling mechanism 4 is used to cool the cotton filament 2; The cotton thread 2 runs through the inside of the separation pipe 6, the inside of the separation pipe 6 is equipped with the clamping mechanism 7, the separation pipe 6 is used to discharge the fluff, and the clamping mechanism 7 is used fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap