Hydrogen supply device for chemical hydrogen production and nanometer hydrogen dissolution water machine using chemical hydrogen production as hydrogen source

A hydrogen-dissolving water machine and chemical technology, applied in the field of nano-hydrogen-dissolving water machines, can solve the problems of high cost, waste, and low hydrogen production by the hydrogen-dissolving machine, and achieve the effect of saving costs and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will now be further described with reference to the accompanying drawings.

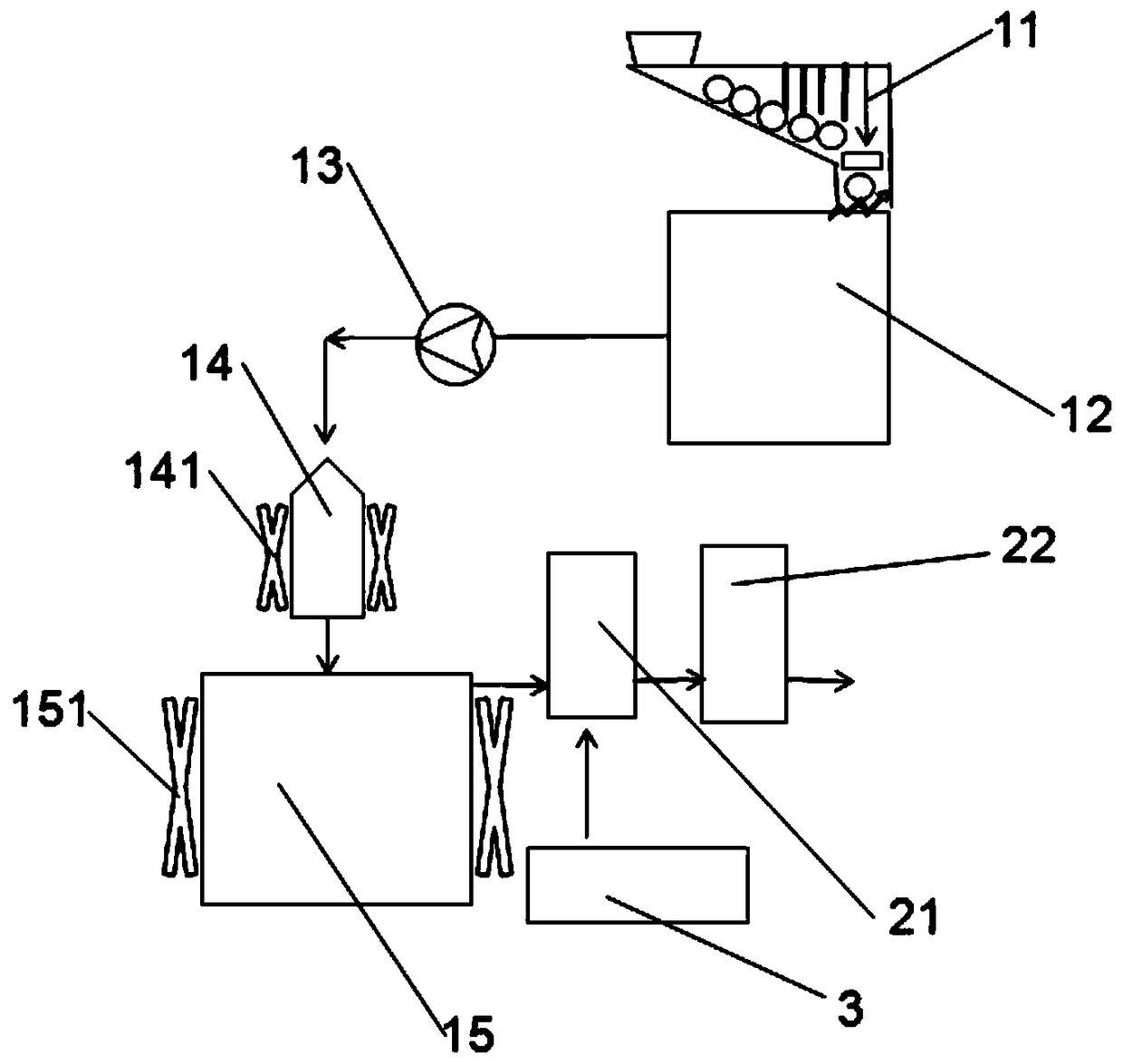

[0029] figure 1 Shown is a schematic structural diagram of the hydrogen supply device for chemical hydrogen production disclosed in this embodiment, which includes a hydrogen generating mechanism, a conveying mechanism and a cooling unit 3 . The hydrogen generating mechanism is used for producing hydrogen by reaction, the conveying mechanism is used for transporting the produced hydrogen to the hydrogen dissolving device, and the cooling unit 3 is used for cooling the device.

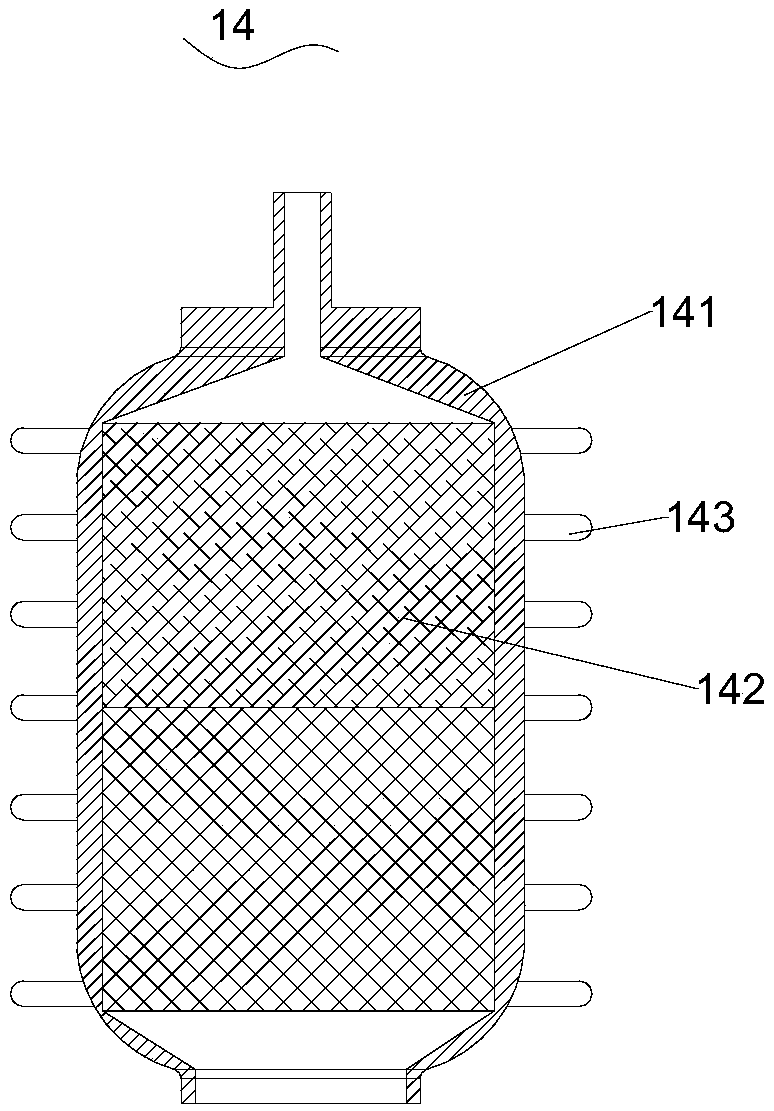

[0030] The hydrogen generating mechanism includes a medicament box 11 , a solution tank 12 , a peristaltic pump 13 , a reactor 14 and a waste liquid tank 15 which are connected in sequence.

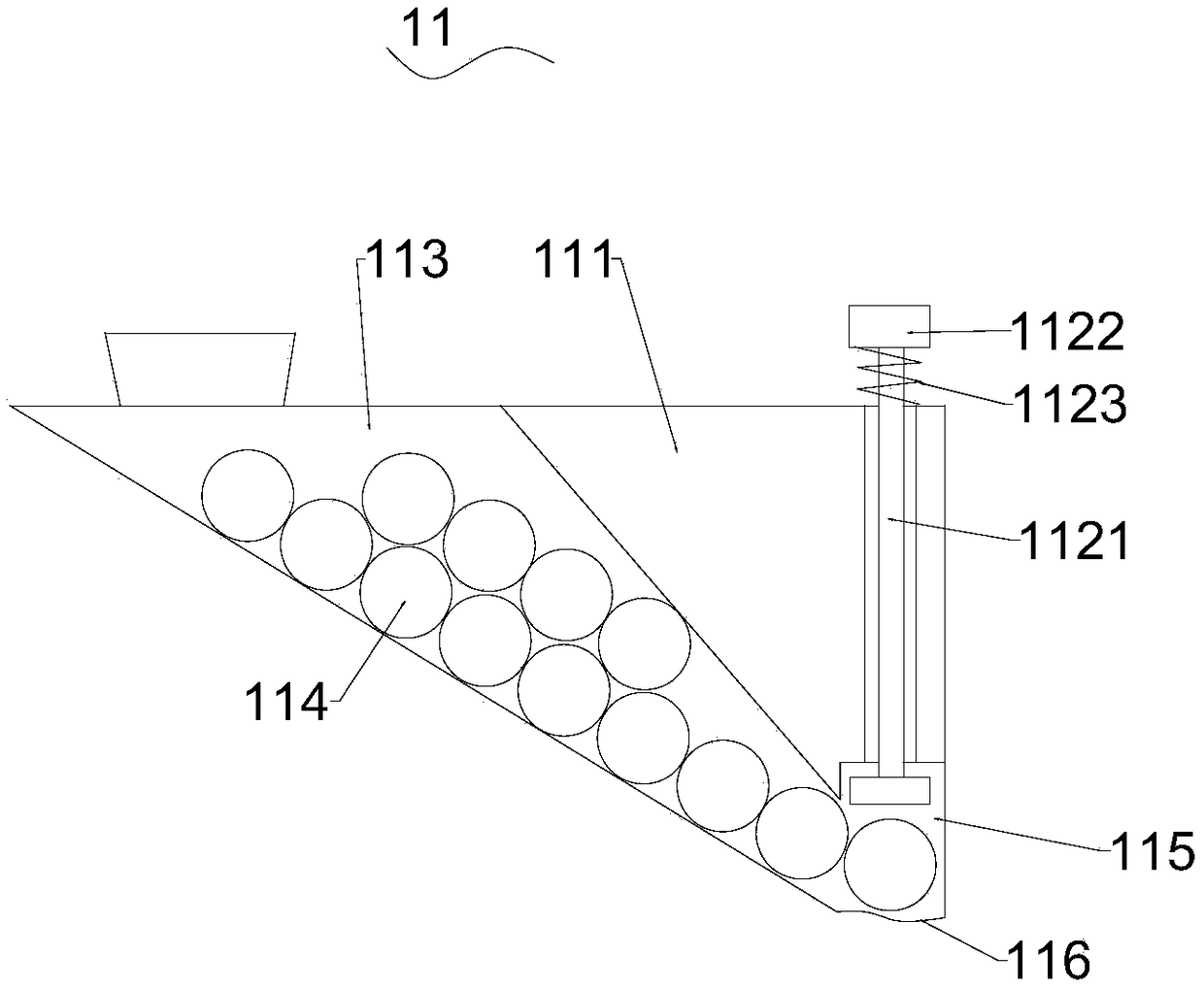

[0031] see figure 2 , the medicine box 11 includes a box body 111 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com