High-sand and high-viscosity oily sludge pretreatment method and pretreatment system

A technology for oily sludge and pretreatment, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve viscous agglomerated sludge breaking and dispersing, centrifuge failure problems such as high sand content and high viscosity sludge cannot be effectively treated, so as to ensure continuous and stable operation and reduce the treatment load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

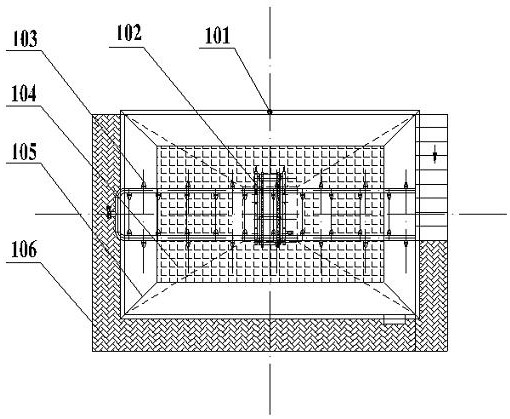

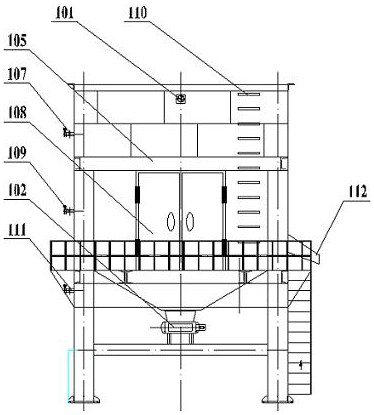

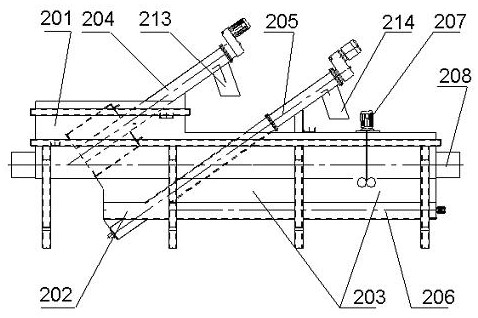

[0047] An oil field built a 24m 3 / d The oily sludge treatment station is used to treat the oily sludge produced by the low-permeability block and the chemical flooding surface treatment system. The treatment process adopted is "screening fluidization pretreatment→chemical conditioning→centrifugal dehydration". Since the sludge to be treated is mixed sludge from low-permeability blocks and chemical flooding surface systems, it has high sand content (mass ratio 15%-35%) and high sludge viscosity (2mPa.s-5mPa.s) and other characteristics, the conventional pretreatment method and device selected in the original design could not meet the requirements of standard treatment, so the method and device proposed by this patent were selected in the subsequent transformation design.

[0048] The material to be processed is first sent to the Φ100mm vibrating grid in the first-level tearing screening area of the third-level tearing screening device through the grab bucket, and the steam n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com