Method for treating flue gas desulfurization wastewater through combination of coagulating sedimentation-aerobics-chemical oxidation

A desulfurization wastewater, chemical oxidation technology, applied in the direction of sedimentation treatment, chemical instruments and methods, multi-stage water treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

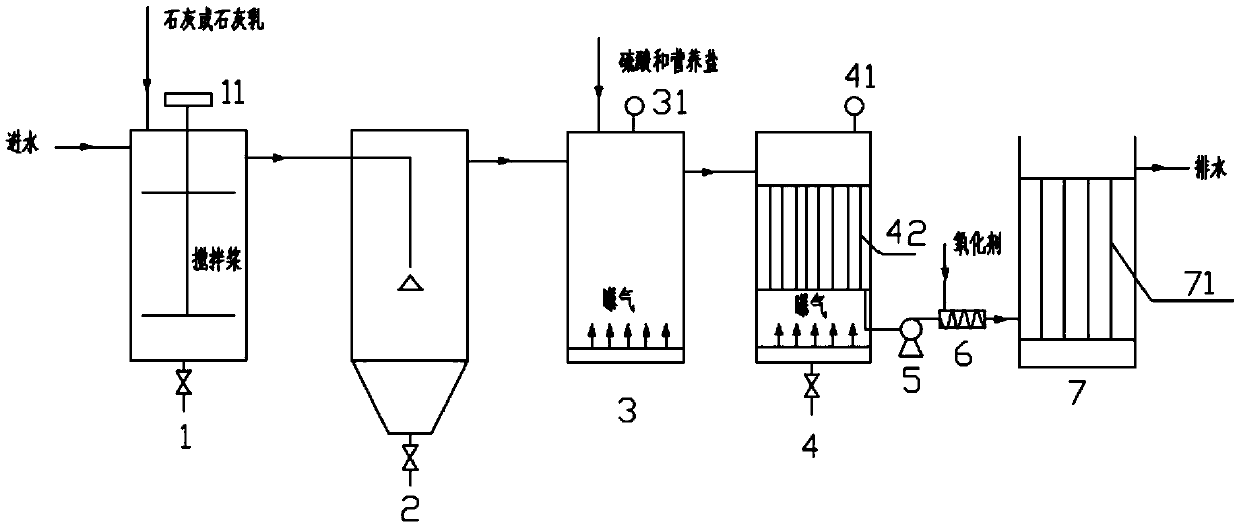

Embodiment 1

[0025] First, add lime milk to the coagulation tank 1 for coagulation treatment. The ratio of lime dry basis to flue gas desulfurization wastewater mass is 0.001, the pH is about 9, and the reaction time is 10 minutes; then the coagulation effluent enters the vertical tank. Flow-type sedimentation tank 2, the sedimentation time is 1 hour; then the sedimentation water enters the intermediate storage tank 3 and adjusts the pH to 7.5 and BOD 5 :N:P is 100:5:1, the hydraulic retention time of the wastewater in the intermediate storage tank 3 is 1 hour; then the wastewater enters the MBR 4, and the hydraulic retention time in the MBR is 4 hours; finally the MBR effluent is in the chemical aerobic tank 7 After being mixed with the added hydrogen peroxide in the pipe static mixer 6 installed on the water inlet pipe, it enters the chemical oxidation tank 7, and the ratio of the hydrogen peroxide dosing quality to the flue gas desulfurization wastewater quality is controlled to be 0.001...

Embodiment 2

[0027] First add lime milk for coagulation treatment. The ratio of lime dry basis to flue gas desulfurization wastewater mass is 0.0015, the pH is about 9.5, and the reaction time is 15 minutes; then the coagulation effluent enters the vertical flow sedimentation tank. The precipitation time is 1.5 hours; then the precipitation water enters the intermediate storage tank and adjusts the pH to 7.5 and BOD 5 :N:P is 100:5:1, the hydraulic retention time of the wastewater in the intermediate storage tank is 1 hour; then the wastewater enters the MBR, and the hydraulic retention time in the MBR is 6 hours; finally, the MBR effluent enters the chemical oxidation tank, and hydrogen peroxide is added The ratio of quality to flue gas desulfurization wastewater quality is 0.0012, the pH of wastewater is 8, the chemical oxidation time is 3 hours, the ultraviolet wavelength is 254nm, the COD of chemical oxidation effluent is 110mg / L, and the fluoride ion concentration is 4.5mg / L, which mee...

Embodiment 3

[0029] First add lime milk for coagulation treatment. The ratio of lime dry basis to flue gas desulfurization wastewater mass is 0.002, the pH is about 10, and the reaction time is 20 minutes; then the coagulation effluent enters the vertical flow sedimentation tank. The precipitation time is 2 hours; then the precipitation water enters the intermediate storage tank and adjusts the pH to 7.5 and BOD 5 :N:P is 100:5:1, the hydraulic retention time of the wastewater in the intermediate storage tank is 1 hour; then the wastewater enters the MBR, and the hydraulic retention time in the MBR is 8 hours; finally, the MBR effluent enters the chemical oxidation tank, and hydrogen peroxide is added The ratio of the quality to the quality of flue gas desulfurization wastewater is 0.0015, the pH of wastewater is 8.5, the chemical oxidation time is 4 hours, the ultraviolet wavelength is 254nm, the COD of chemical oxidation effluent is 98mg / L, and the fluoride ion concentration is 3mg / L, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com