Cultivation method for tobacco sewage flora

A cultivation method and sewage technology, applied in the field of tobacco sewage treatment, can solve problems such as difficulty in meeting discharge standards, poor sludge activity, and poor quality of effluent from the treatment system, and achieve the effect of standard treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

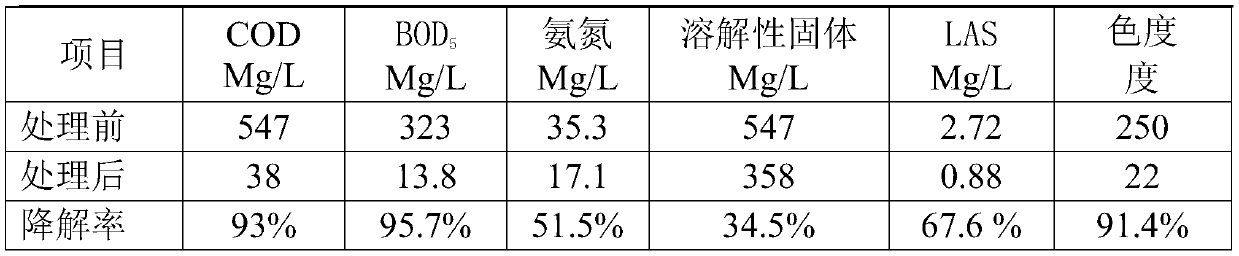

Embodiment 1

[0031] The cultivation method of tobacco sewage flora comprises the following steps:

[0032] Inoculation: Sludge is used for initial inoculation, and biochemical bacteria agents mainly containing Arthrobacter and Pseudomonas are added to expand and strengthen the cultivation. The sludge is also used as a carrier of bacteria.

[0033] Dosing sludge: inject a certain amount of clear water and tobacco sewage to be treated into the biochemical pool, pour the inoculated sludge into the biochemical pool, the amount of sludge added is 0.6% (vt) of the effective volume of the biochemical pool, add water and stir Uniform, adjusted to 80% (vt) water content in the pool, forming uniform activated sludge;

[0034] Add culture material, nitrogen source, phosphorus source: Add culture material with glucose as the main component, control the concentration of COD in the biochemical pool to be about 300mg / L; then press m(BOD5):m(N):m(P)= 100:5:1, add ordinary calcium superphosphate (hereinaf...

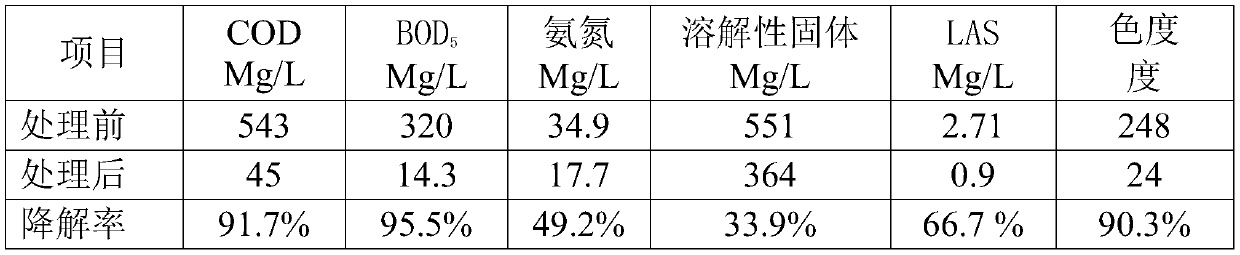

Embodiment 2

[0045] The cultivation method of tobacco sewage flora comprises the following steps:

[0046] Inoculation: Sludge is used for initial inoculation, and the sludge is also used as a carrier of bacteria, and biochemical bacteria agents mainly containing Arthrobacter and Pseudomonas are added to expand and strengthen the cultivation.

[0047] Dosing sludge: inject a certain amount of clear water and tobacco sewage to be treated into the biochemical pool, pour the inoculated sludge into the biochemical pool, the amount of sludge added is 0.5% (vt) of the effective volume of the biochemical pool, add water and stir Uniform, adjusted to 70% (vt) water content in the pool, forming uniform activated sludge;

[0048] Add culture material, nitrogen source, and phosphorus source: Add culture material with glucose as the main component, control the concentration of COD in the biochemical pool to 250mg / L; then press m(BOD5):m(N):m(P)=90 :4:1, adding common calcium superphosphate (hereinaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com