Solvent-free polyurethane adhesive layer resin for football leather and its preparation method and application

A solvent-free polyurethane and bonding layer technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems that the quality of finished leather cannot meet the standards, and achieve improved processing performance, good fluidity, Excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

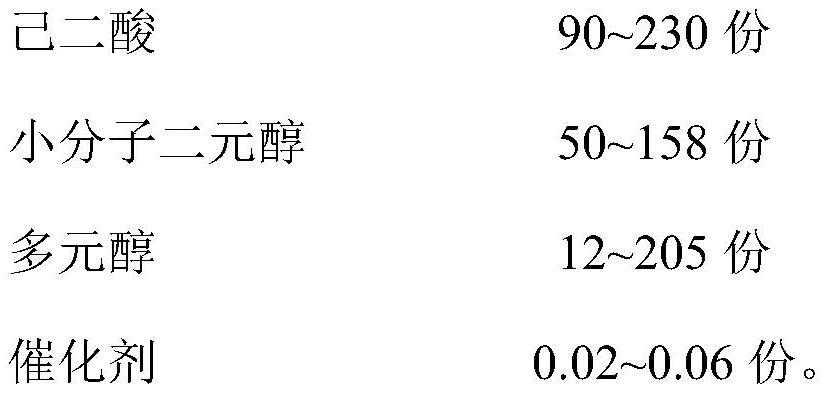

[0043] (1) Preparation of polyester polyol

[0044]A four-necked flask equipped with a magnetic stirrer, a thermometer, a nitrogen inlet tube and a condenser tube was installed in a jacketed resistance heater, and 90 parts of adipic acid, 50 parts of diethylene glycol and 205 parts of castor were added to the flask. Sesame oil, vent nitrogen to get rid of the air in the flask; then gradually heat up under the protection of nitrogen to carry out dehydration polycondensation reaction, control the top temperature of the condenser tube during the temperature rise process to be lower than 105°C; when the acid value of the reaction solution is 5mgKOH / g, Add 0.02 parts of tetraisopropyl titanate to continue the reaction for 0.5h, then gradually heat up to 200°C, vacuum degree ≥ 0.095MPa, continue the reaction to make the hydroxyl value of the reaction solution reach 56mgKOH / g, and obtain a polyester multi-component with a molecular weight of 2000 alcohol;

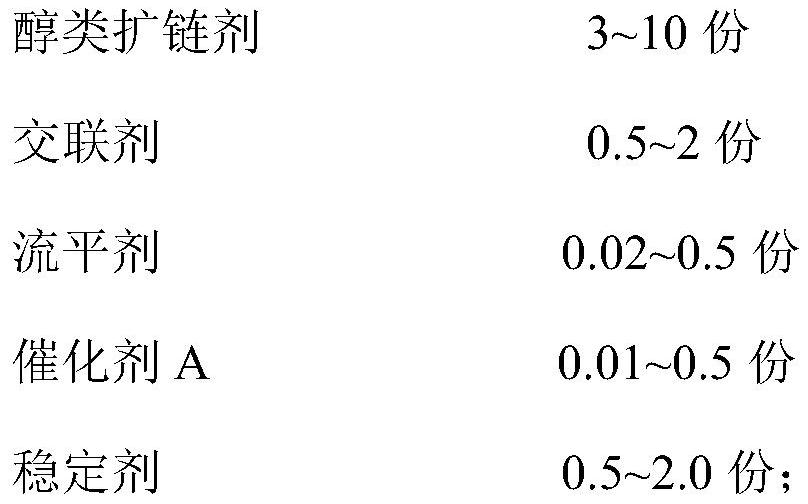

[0045] (2) Preparation of...

Embodiment 2

[0057] (1) Preparation of polyester polyol

[0058] Equipped with magnetic stirrer, thermometer, N 2 The four-necked flask with the inlet pipe and the condenser pipe is installed in a jacketed resistance heater, and 230 parts of adipic acid, 158 parts of 1,4-butanediol and 12 parts of trimethylolpropane are added to the flask, and the flask is vented with nitrogen. Then, under the protection of nitrogen, gradually heat up the temperature to carry out the dehydration polycondensation reaction, and control the top temperature of the condenser tube to 105°C during the temperature rise process; when the acid value of the reaction liquid is 10mgKOH / g, add 0.04 parts of tetraisopropyl titanate Continue to react with the ester catalyst for 1 hour, then gradually heat up to 260°C, vacuum degree ≥ 0.095MPa, continue the reaction so that the hydroxyl value of the reaction solution reaches 74.8mgKOH / g, and obtain a polyester polyol with a molecular weight of 1500;

[0059] (2) Preparati...

Embodiment 3

[0071] (1) Preparation of polyester polyol

[0072] Equipped with magnetic stirrer, thermometer, N 2 The four-necked flask with the inlet pipe and the condenser pipe is installed in a jacketed resistance heater, and 200 parts of adipic acid, 100 parts of 3-methyl-1,5-pentanediol and 35 parts of pentaerythritol are added to the flask, and nitrogen gas is used to remove The air in the flask; then gradually heated up under the protection of nitrogen to carry out dehydration polycondensation reaction, during the temperature rise process, the temperature at the top of the condenser tube was controlled to be lower than 105°C; when the acid value of the reaction solution was 20mgKOH / g, add 0.06 parts of titanic acid Continue to react tetrabutyl ester for 1.5h, then gradually heat up to 280°C, vacuum degree ≥ 0.095MPa, continue the reaction to make the hydroxyl value reach 112mgKOH / g, and obtain a polyester polyol with a molecular weight of 1000;

[0073] (2) Preparation of Component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com