Liquor brewing device

A technology for installing chambers and steam boxes, which is applied in the field of wine-making devices, can solve the problems of reducing the efficiency of wine distillation, unstable alcohol concentration, and difficulty in adding water, etc., and achieve the effect of expanding the contact direction and facilitating full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further detailed explanation through specific implementation mode below:

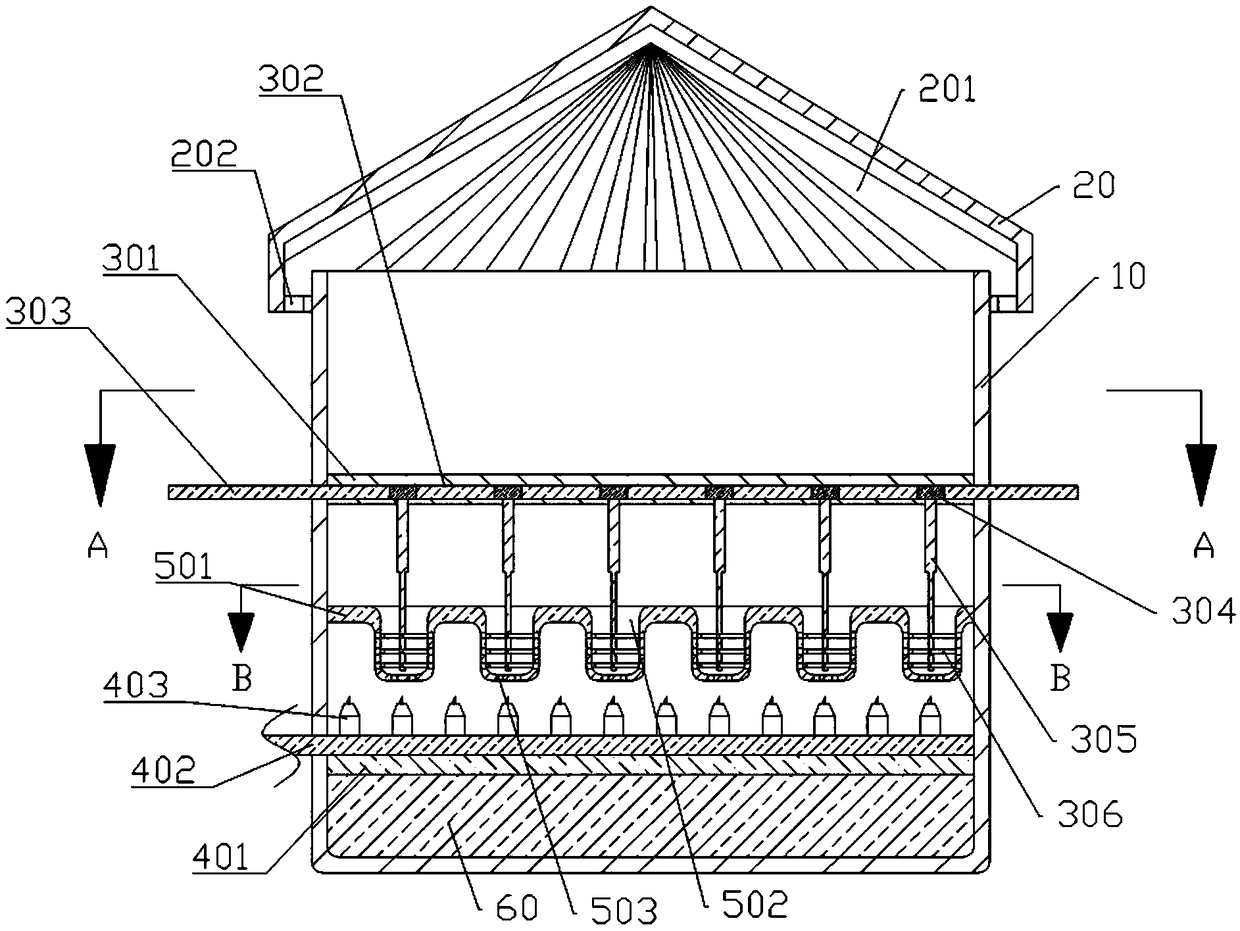

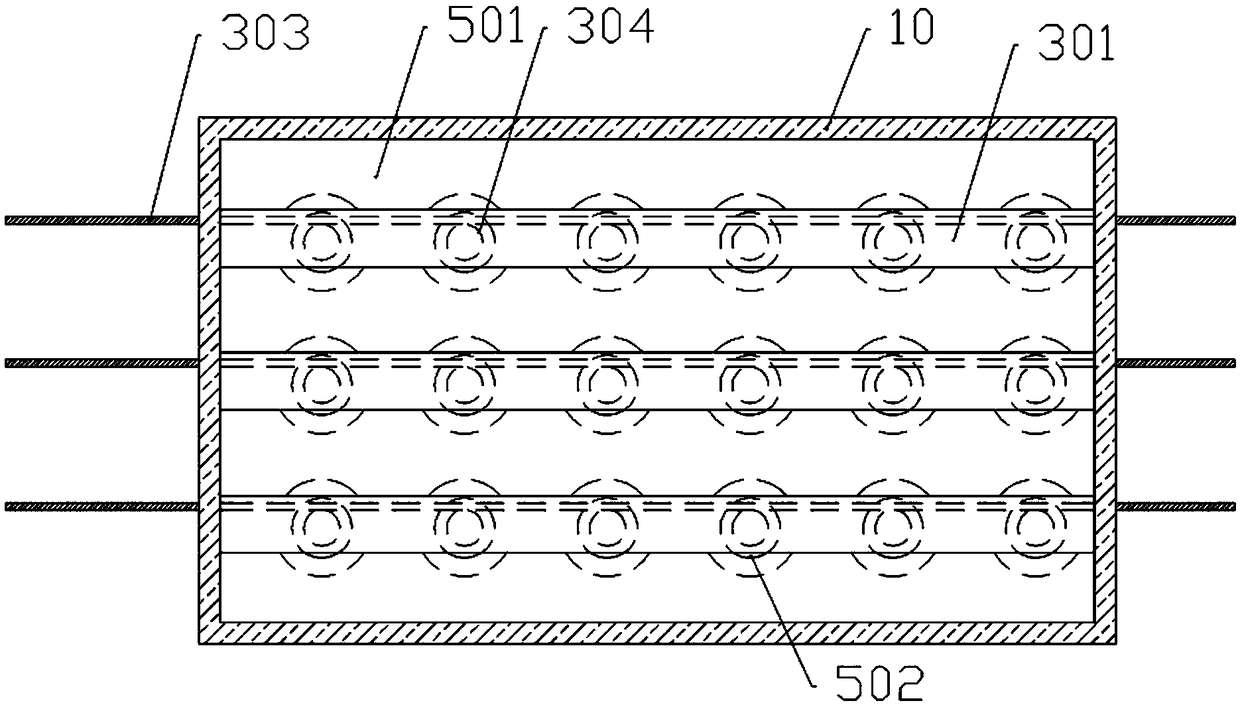

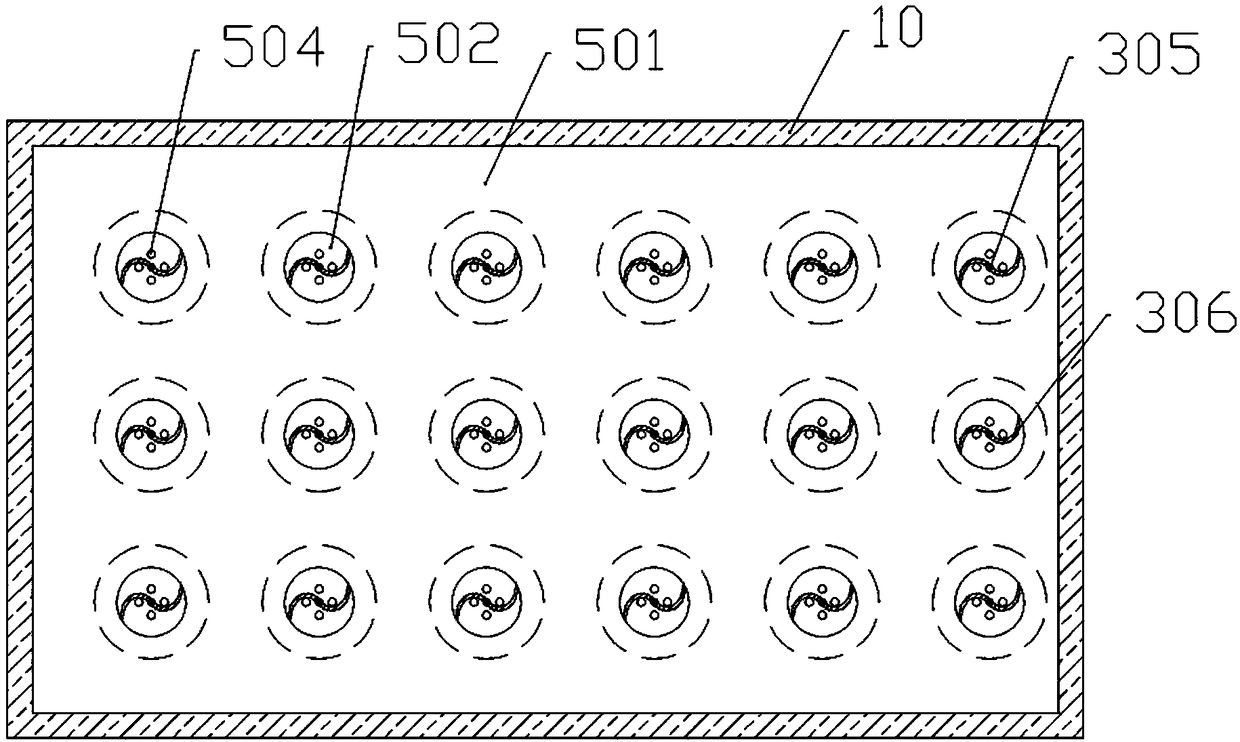

[0018] The reference signs in the accompanying drawings include: steamer 10, box cover 20, diversion groove 201, collection hole 202, guide rod 301, installation cavity 302, rack 303, gear 304, stirring rod 305, stirring knife 306, Heat conduction plate 401 , water spray pipe 402 , atomizing nozzle 403 , receiving plate 501 , groove 502 , through hole 503 , and electric furnace 60 .

[0019] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: a device for brewing wine, including a steam box 10, a box cover 20, a quantitative water spray mechanism and three stirring mechanisms, the box cover 20 is detachably connected to the steam box 10, and the bottom of the steam box 10 is equipped with a heating mechanism, a receiving plate 501 is installed horizontally and detachably in the steamer 10 . like figure 1 As shown, the stirring mechanism, the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com