980MPa grade cold-rolled dual-phase steel with low requirements for cooling capacity of production line and manufacturing method thereof

A technology of cooling capacity and manufacturing method, which is applied in the field of steelmaking, and can solve problems such as the lack of an ultra-high-strength production line, difficulty in controlling the stability of on-site production, and high requirements for the cooling capacity of the production line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

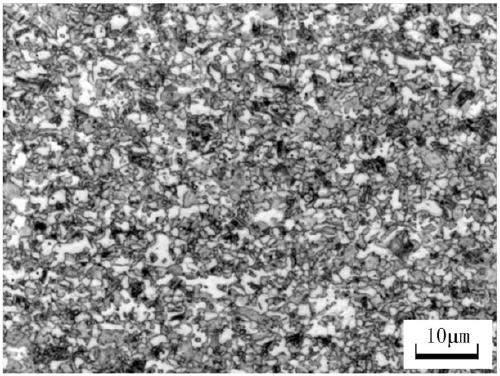

Image

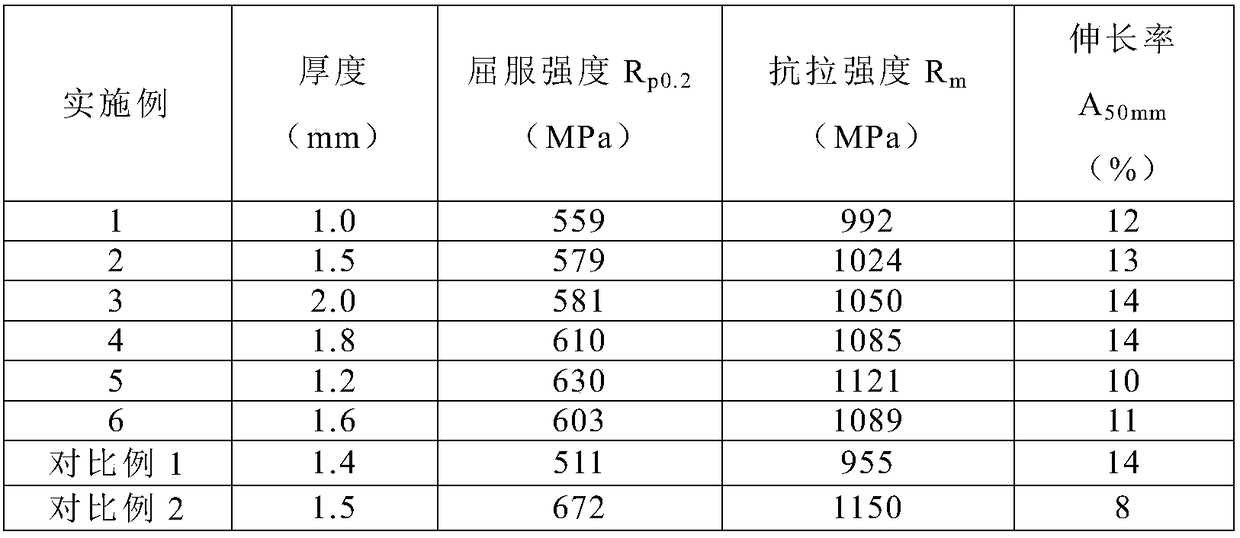

Examples

Embodiment 1

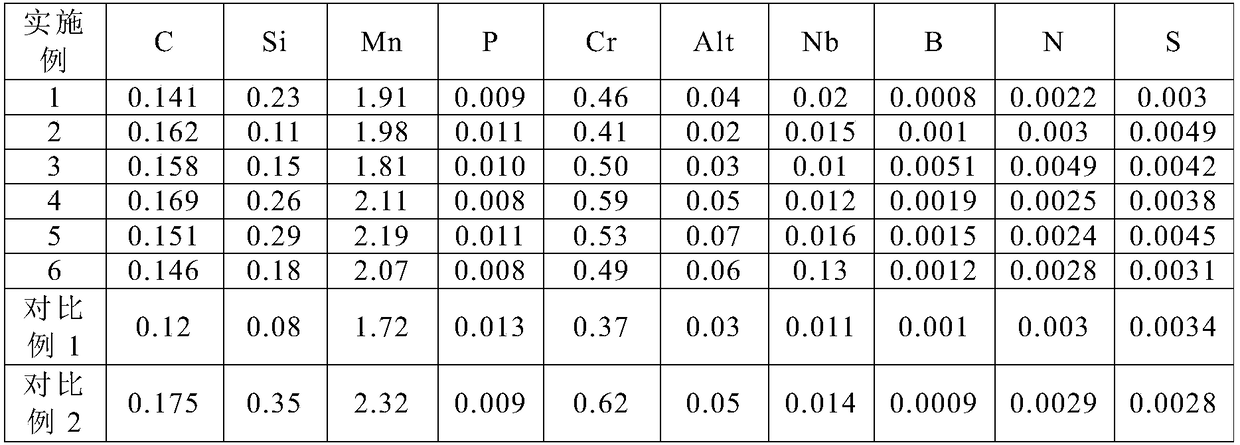

[0058] This embodiment provides a 980MPa grade cold-rolled dual-phase steel with low requirements on the cooling capacity of the production line, which is composed of the following chemical components in mass percentages: C: 0.141%, Si: 0.23%, Mn: 1.91%, P: 0.009%, Cr: 0.46%, Alt: 0.04%, Nb: 0.02%, B: 0.0008%, S: 0.003%, N: 0.0022%, and the balance is Fe and unavoidable impurities.

[0059] The production method of above-mentioned duplex steel, its step is as follows:

[0060] In the hot rolling process, the slab heating temperature is 1270-1282°C, the final rolling temperature is 892-901°C, the coiling temperature is 639-657°C, the cold rolling reduction is 62%, the annealing temperature is 805-812°C during the annealing process, and the slow cooling The end temperature of the section is 629~637°C, the end temperature of the fast cooling section is 301~315°C, the cooling rate of the slow cooling section is 6°C / s, the cooling rate of the fast cooling section is 25°C / s, the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com