Mining bolt-grouting device and use method thereof

An anchoring, mining technology, applied in mining equipment, earthwork drilling, bolt installation, etc., can solve the problems of reducing the overall support effect, unable to reuse, unable to achieve full-length anchoring, etc., to reduce the labor intensity of workers , The effect of high overall support strength and reduction of roadway maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

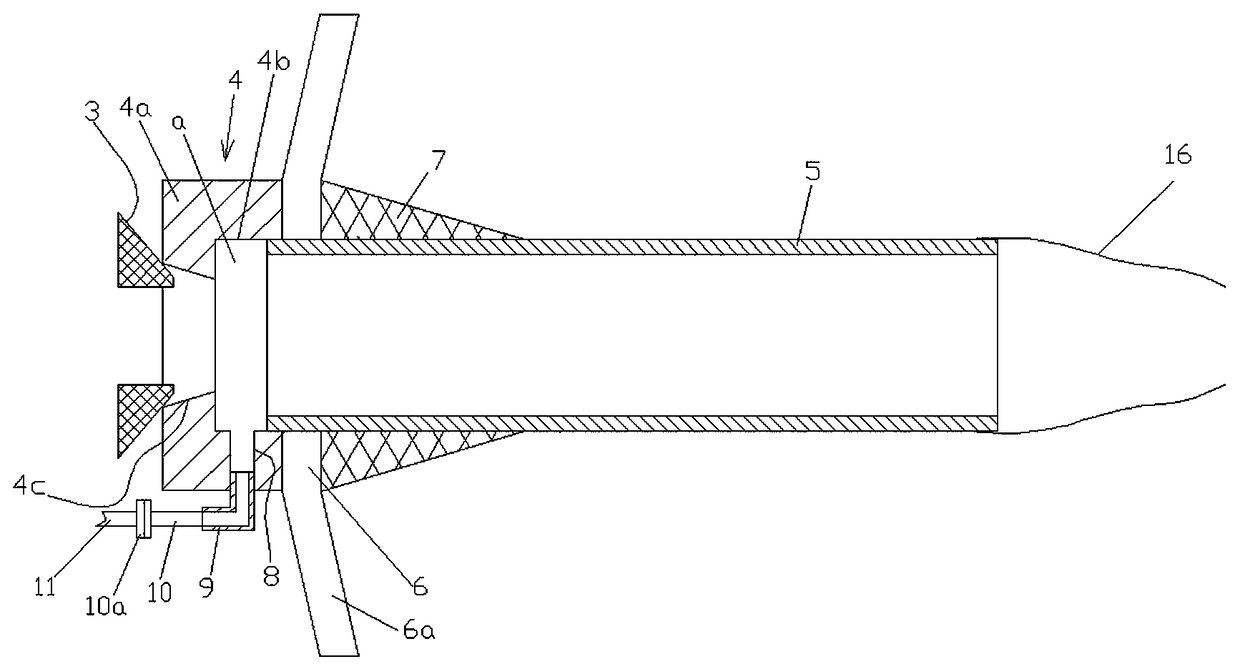

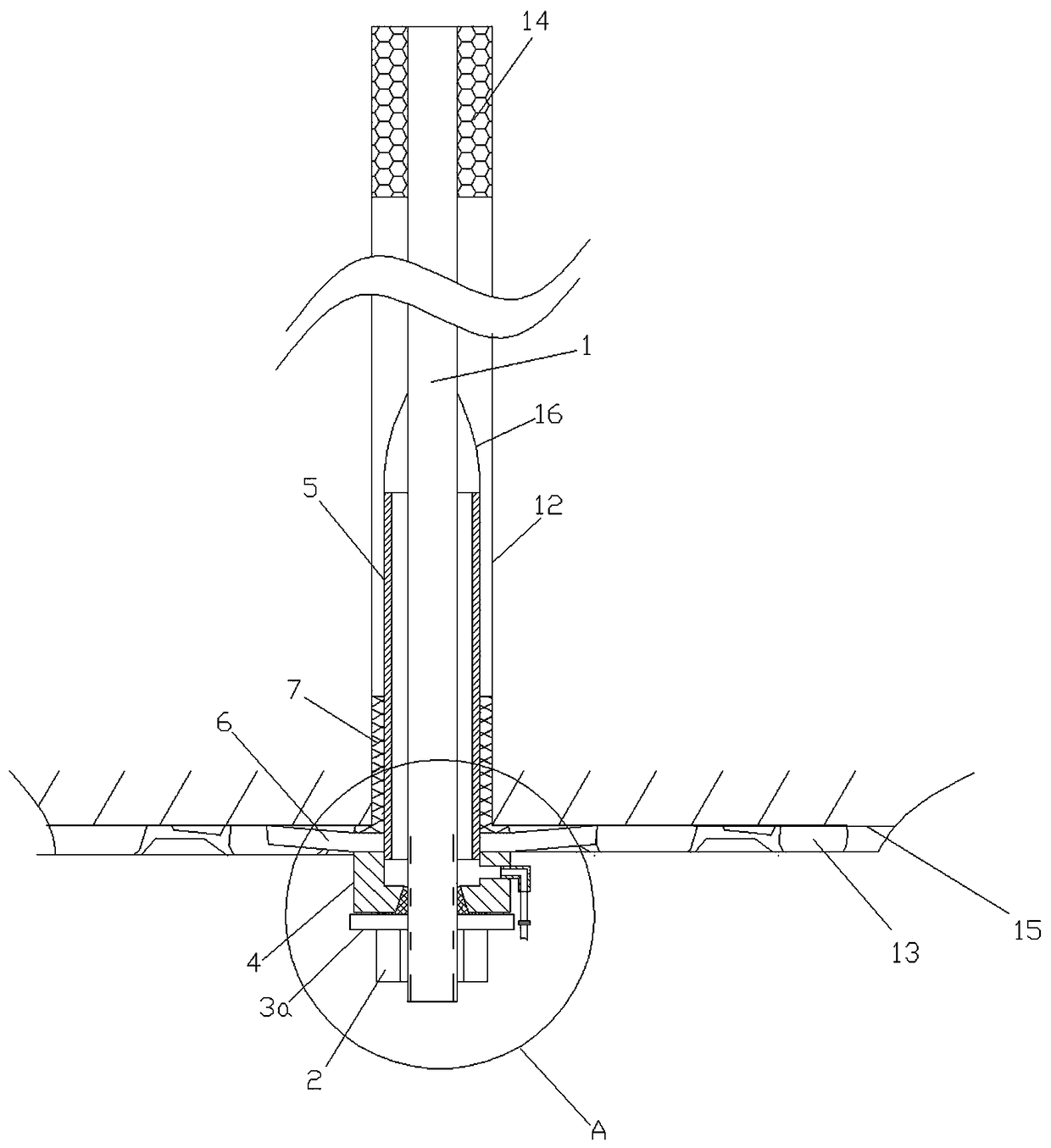

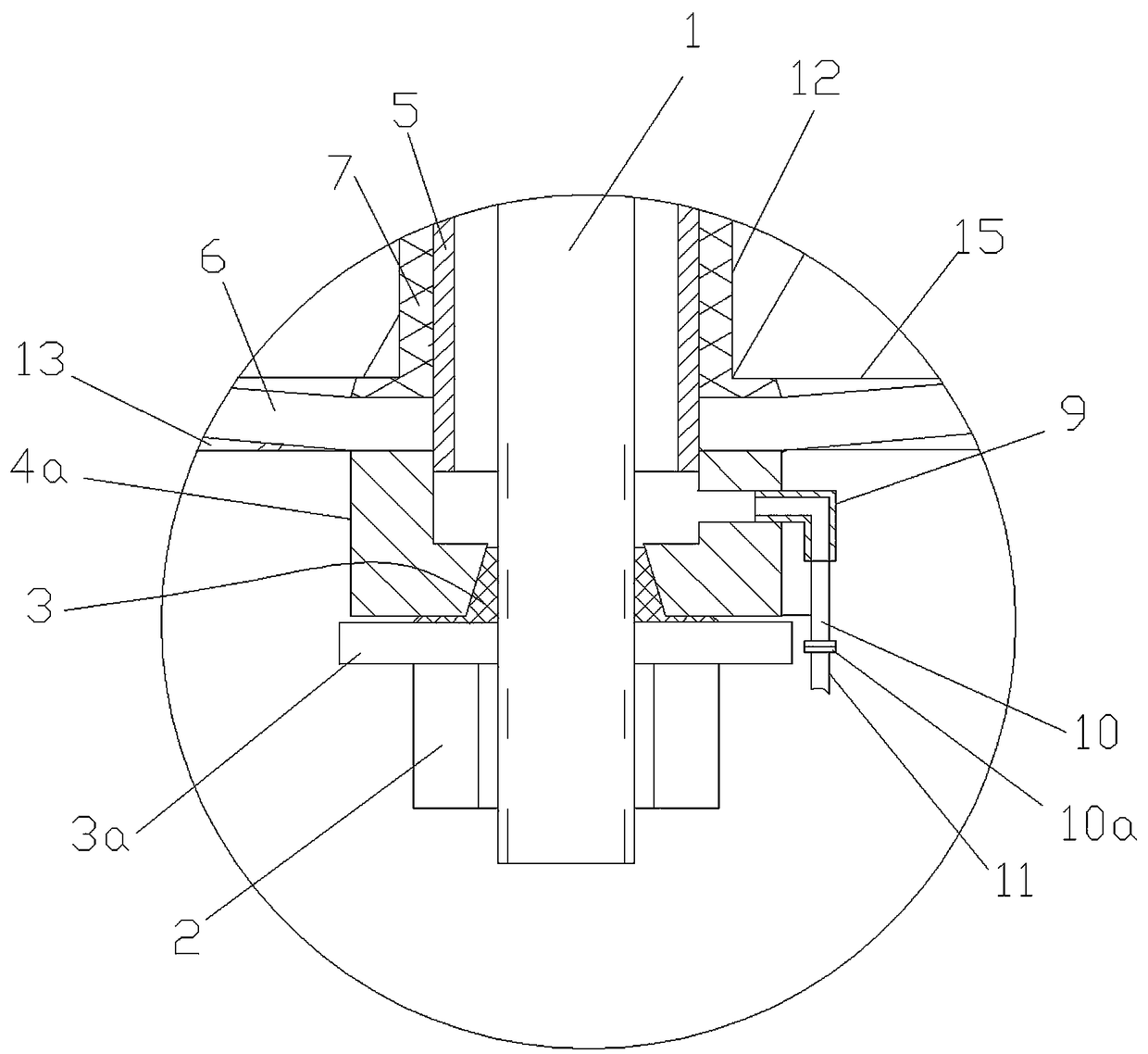

[0021] like Figure 1-4 Shown, a kind of mine anchor injection device of the present invention, it comprises anchor rod 1, is provided with anchor injection device on anchor rod 1, and described anchor injection device it comprises grouting seat 4a, is set on grouting seat 4a There is a through hole 4b corresponding to the threaded anchor rod 1. The through hole 4b is a stepped hole. The stepped hole includes a small aperture section and a large aperture section. A circle of coaxially distributed inverted holes is provided at one end of the small aperture section. Angle 4c.

[0022] A coaxially distributed sealing ring 3 is sheathed on the shaft of the anchor rod 1 on one side of the small-aperture section. The sealing ring 3 is conical, and the conical head at one end is inserted into the chamfer 4c.

[0023] A grouting pipe 5 is inserted into the large aperture section of the through hole 4b, and the grouting pipe 5 is coaxially distributed with the anchor rod 1, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com