Negative pressure ventilating and dust removing device for mine

A technology of negative pressure ventilation and dust removal device, applied in mine/tunnel ventilation, safety device, dust prevention and other directions, can solve the problems of coal dust explosion, mine equipment damage, waste of manpower and material resources, etc., to increase the dust collection speed, The effect of increasing the dust removal capacity and improving the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

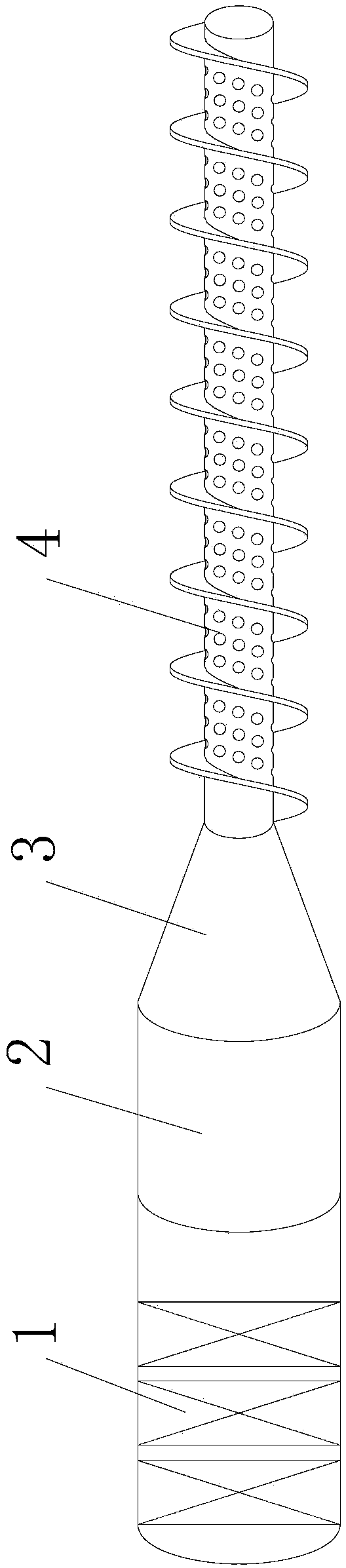

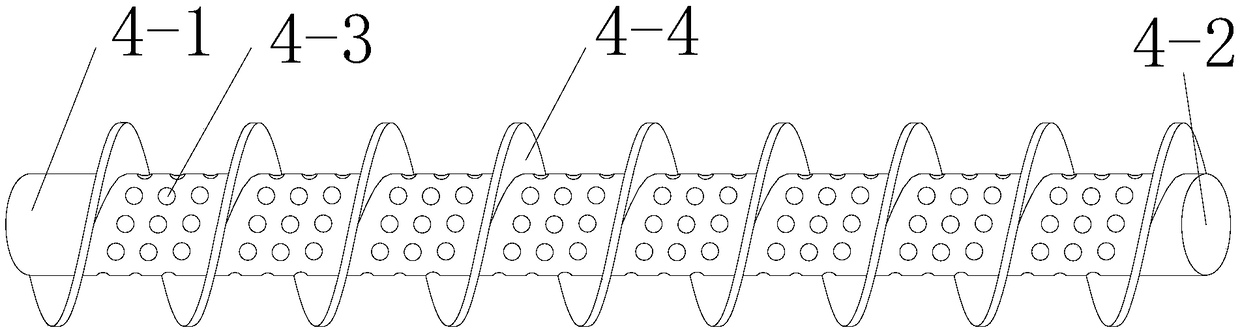

[0024] Such as figure 1 and figure 2 As shown, the present invention includes negative pressure ventilation and dust removal device for mining, which is characterized in that: it comprises a blower 2, a multi-stage fan 1 communicated with one end of the blower 2 and a trumpet-shaped connecting pipe 3 communicated with the other end of the blower 2, the horn One end of the connecting pipe 3 away from the blower tube 2 is connected with an air collecting pipe 4, and the bell mouth of the trumpet connecting pipe 3 communicated with the blowing pipe 2 is larger than the bell mouth of the trumpet connecting pipe 3 communicating with the air collecting pipe 4, and the air collecting pipe 4 includes a pipe body 4-1 and the air guiding fin 4-4 spirally arranged on the pipe body 4-1, and the air collecting pipe section between two adjacent coils in the air guiding fin 4-4 is provided with a plurality of meshes 4 -3, one end of the pipe body 4-1 communicates with the trumpet-shaped co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com