A real-time method for measuring the absolute emission of tunnel gas

A technology for real-time measurement and emission, which is applied in earthwork drilling, mining equipment, mining equipment, etc., can solve the problems of inability to continuously monitor the gas concentration and the inability to continuously measure the parameters of the maximum gas emission, so as to improve the propulsion Accurate effect on efficiency and absolute gas emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

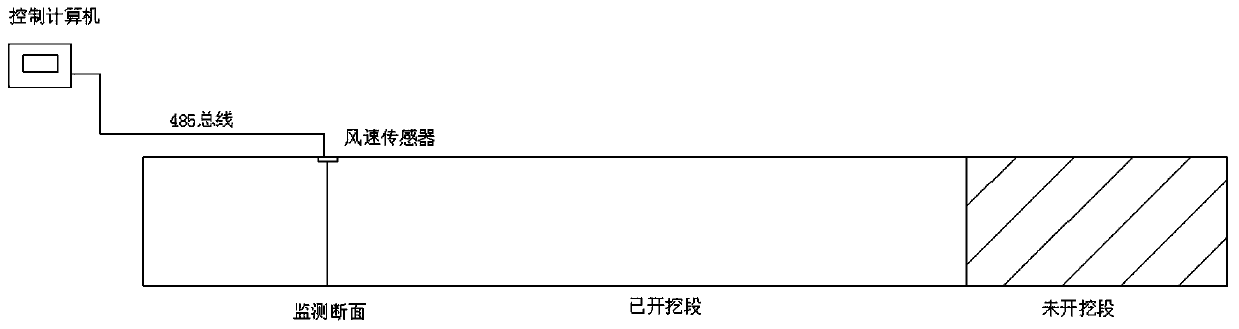

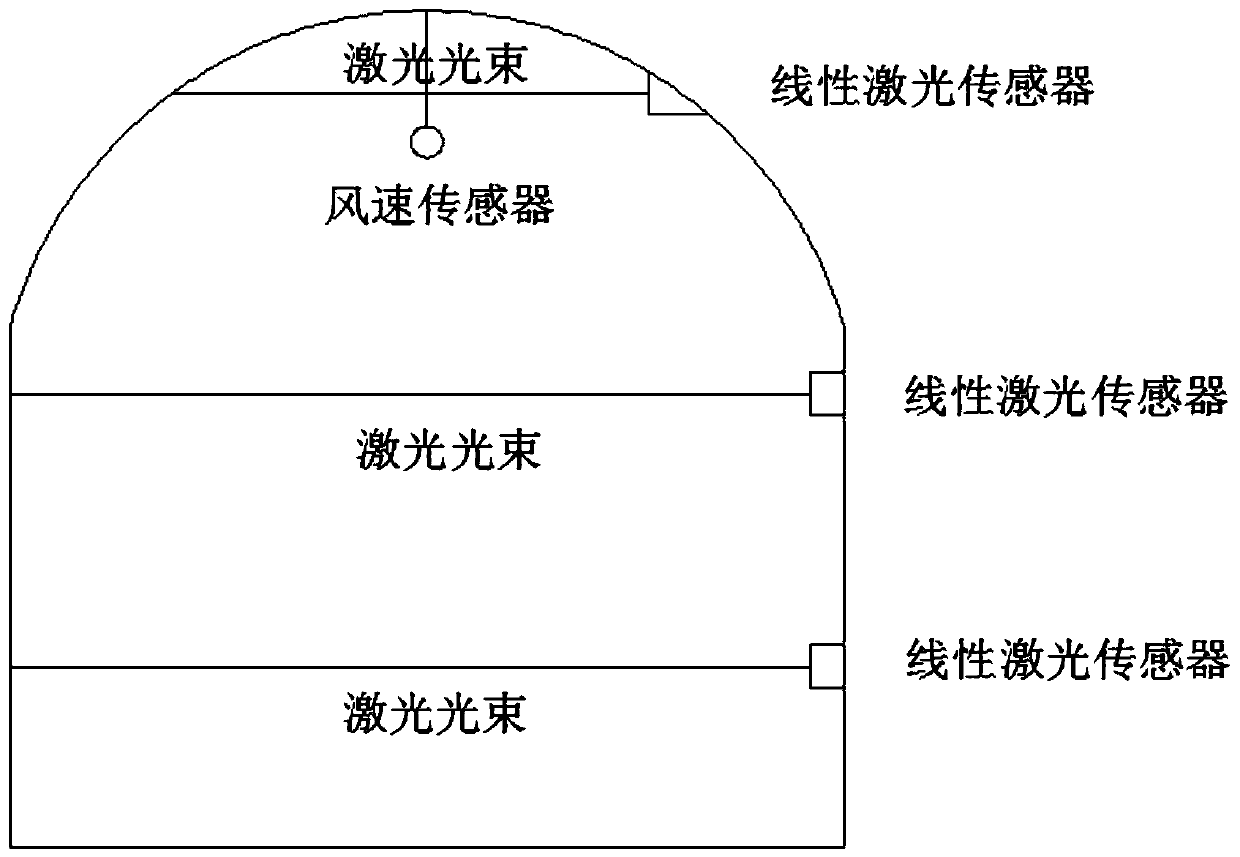

[0022] Such as figure 1 As shown, a method for real-time measurement of the absolute gas emission in a tunnel, the method includes the following steps: S1: Install a linear laser sensor on one side of the tunnel section, and arrange three groups from top to bottom, of which the first group is installed 30cm below the tunnel vault, the other two groups are installed evenly according to the height of the tunnel, and the linear laser sensor is irradiated to the other side of the tunnel section, and the average concentration of gas on the beams of the three groups is measured; S2: Install the wind speed sensor in step S1 The laser sensor measured the wind speed of the tunnel section at 50cm below the vault of the same tunnel section; the wind speed sensor detection data was compared with the manual detection data, and the correction between the measured value of the wind speed sensor at this point and the average wind speed value of the tunnel was obtained under different wind spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com