A pinch valve

A sandwich and diaphragm technology, which is applied in the direction of diaphragm valves, diaphragms, valve devices, etc., can solve problems such as easy blockage, large pump body, and poor passability of the pump body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings of the description.

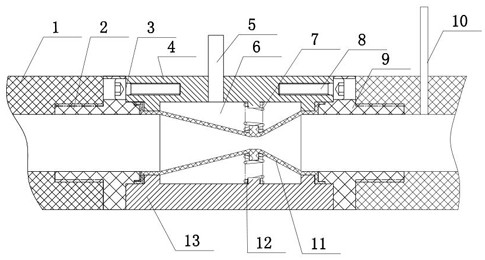

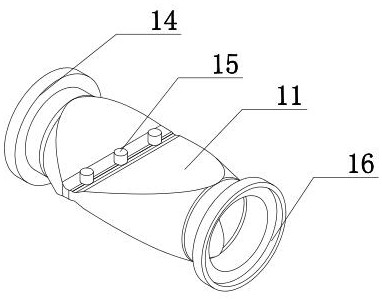

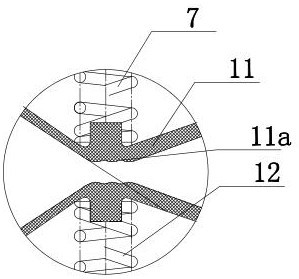

[0015] As shown in the figure, the sandwich valve includes a discharge pipe 1, and a fish-shaped film 11 is arranged in the cavity of the discharge pipe 1. The length of the left and right sides of the fish-shaped film 11 is one side long and one side short. When it is opened, a jet nozzle structure is formed. The long side is the acceleration section, and the short side is the deceleration section, which is conducive to the discharge of the medium. In the closed state, the upper and lower diaphragms in the middle of the fish-shaped sandwich 11 are sealed and bonded. One end of the long pipe of the fish-shaped sandwich 11 is connected to the sewage device such as a toilet, and one end of the short pipe of the fish-shaped sandwich 11 is connected to the negative pressure station. A vacuum drainage interface 10 is arranged on the short pipe of the memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com