A low-pressure liquid circuit integrated block and its processing technology

A processing technology and integrated block technology, applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problems of unfavorable production and manufacturing, small liquid pipe diameter, messy equipment and pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

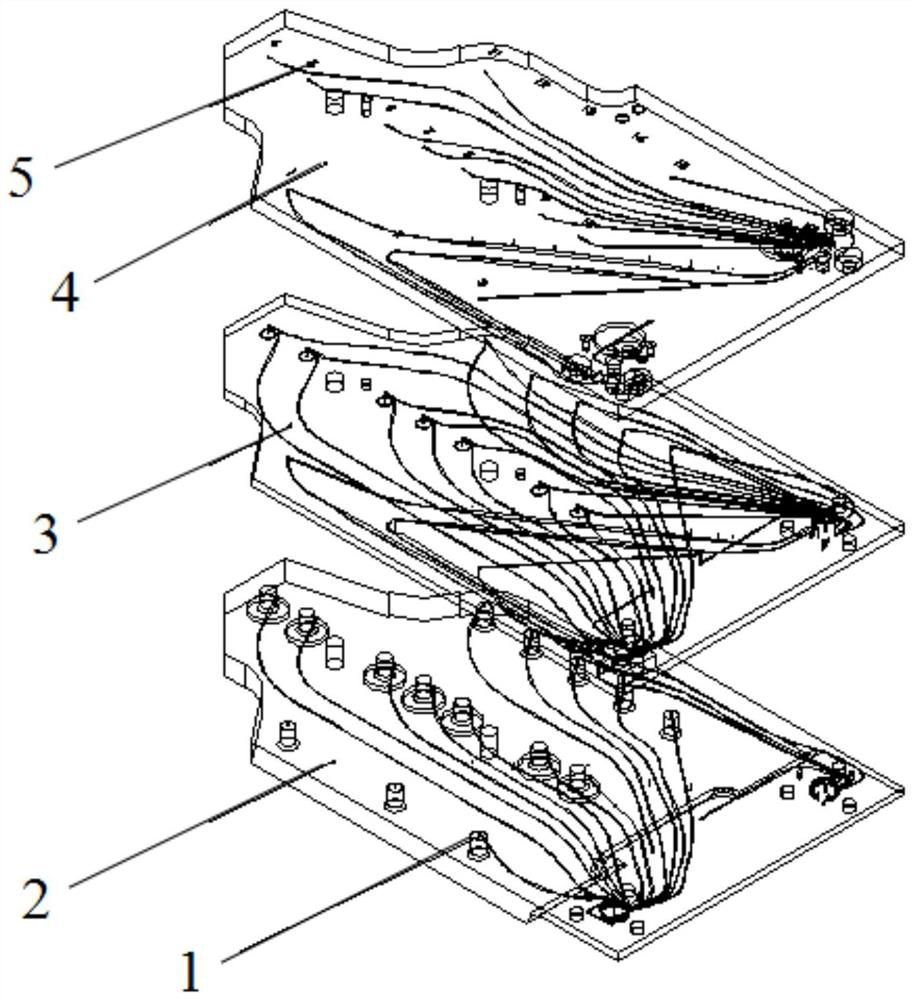

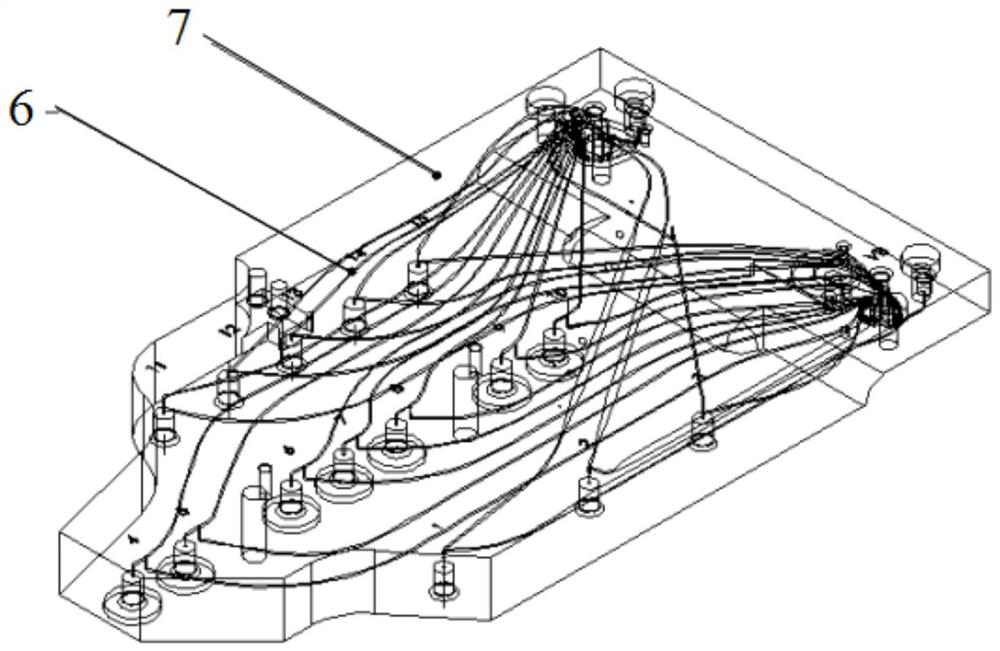

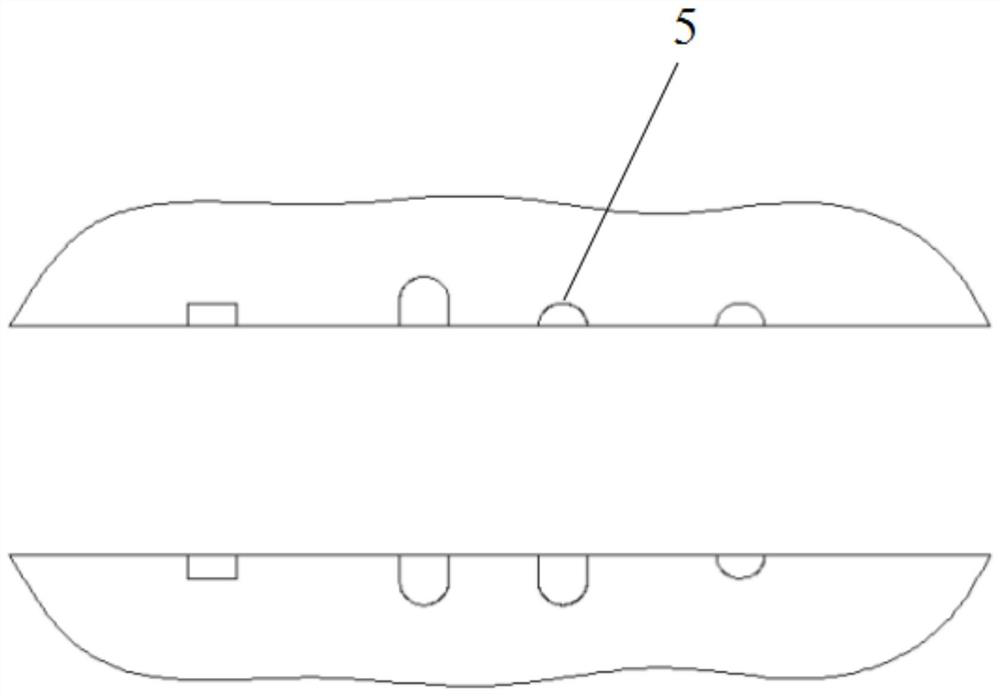

[0026] like figure 1 , figure 2 As shown, a low-pressure liquid circuit integrated block, the liquid circuit integrated block 7 includes a lower substrate 2, an intermediate substrate 3 and an upper substrate 4, the upper surface of the lower substrate 2, the front and back of the intermediate substrate 3 and the lower surface of the upper substrate 4 Half of the flow channel groove 5 is provided on the surface, the middle layer substrate 3 is bonded to the lower layer substrate 2 and the upper layer substrate 4 respectively, half of the flow channel groove 5 on the lower surface of the middle layer substrate 3 is connected to half of the upper surface of the lower layer substrate 2 The two runner grooves 5 are mirror images of each other, and the runner grooves 5 that are mirror images of each other are bonded to form a sealed runner 6. Half of the runner grooves 5 on the upper surface of the middle layer substrate 3 and half of the lower surface of the upper substrate 2 Th...

Embodiment 2

[0030] A processing technology for a low-pressure hydraulic circuit integrated block, the processing technology includes the following steps:

[0031] (A) Select the lower substrate 2, the middle substrate 3 and the upper substrate 4 for making the integrated block 7, the materials of the lower substrate 2, the middle substrate 3 and the upper substrate 4 are polymethyl methacrylate (PMMA), and use CNC precision milling technology mills half of the runner groove 5 on the upper surface of the lower substrate 2, the front and back of the middle substrate 3, and the lower surface of the upper substrate 4, and the half runner groove 5 on the lower surface of the middle substrate 3 is connected with the lower surface. Half of the flow channel grooves 5 on the upper surface of the substrate 2 are mirror images of each other, and half of the flow channel grooves 5 on the upper surface of the intermediate layer substrate 3 and half of the flow channel grooves 5 on the lower surface of ...

Embodiment 3

[0036] A processing technology for a low-pressure hydraulic circuit integrated block, the processing technology includes the following steps:

[0037] (A) Select the lower substrate 2, the middle substrate 3 and the upper substrate 4 for making the integrated block 7, the materials of the lower substrate 2, the middle substrate 3 and the upper substrate 4 are selected from polyetherimide, and the CNC precision milling technology is used The upper surface of the lower substrate 2, the front and back of the intermediate substrate 3, and the lower surface of the upper substrate 4 are milled out half of the flow channel groove 5, and the half of the flow channel groove 5 on the lower surface of the intermediate layer substrate 3 is connected with the upper surface of the lower substrate 2. Half of the flow channel grooves 5 are mirror images of each other, half of the flow channel grooves 5 on the upper surface of the middle layer substrate 3 and half of the flow channel grooves 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com