Magnetic levitation 3D printed moon lamp

A 3D printing and magnetic levitation technology, which is applied in the field of moon lamps, can solve the problems of low changeability, inability to rotate light, low interest and viewing, and achieve high viewing, good visual enjoyment, and strong interest.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

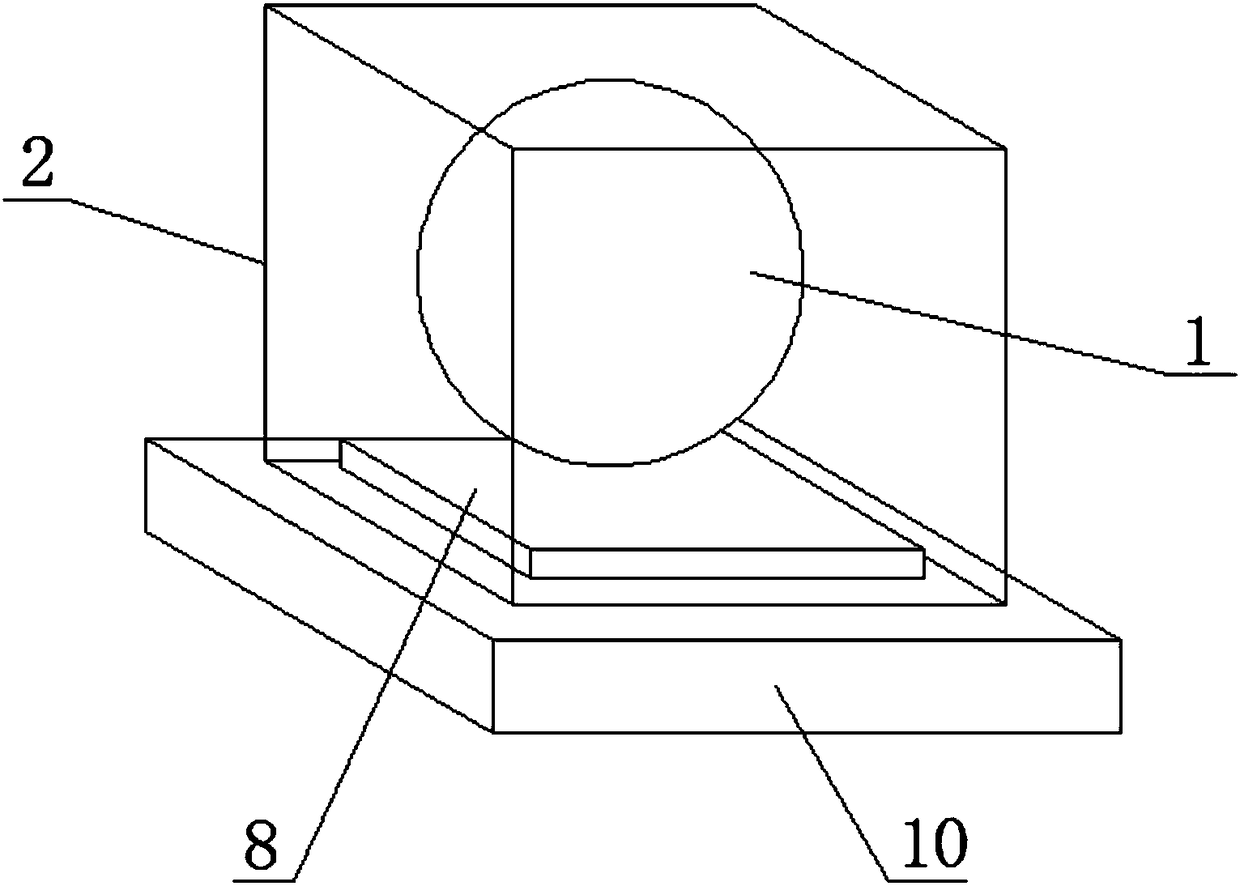

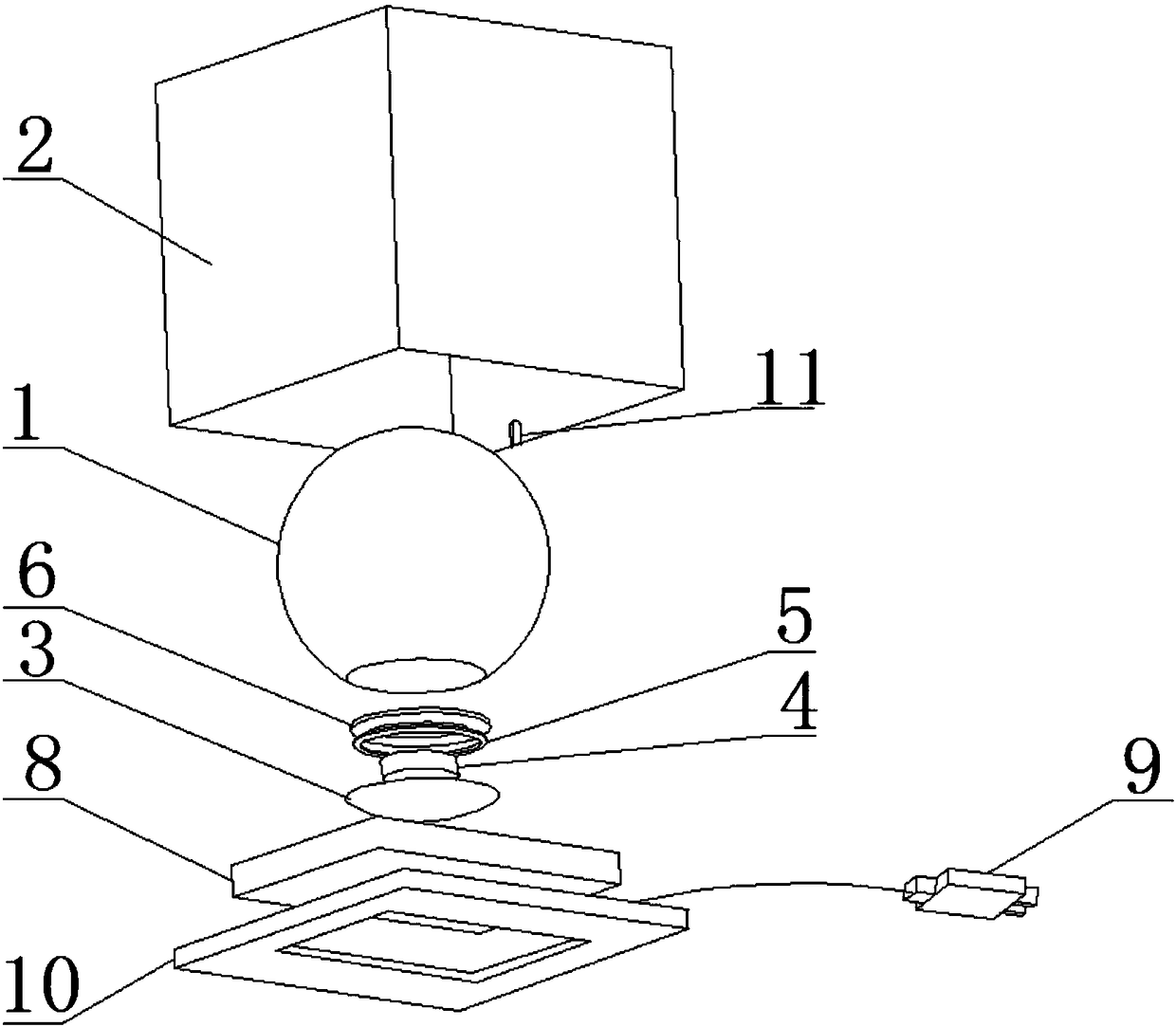

[0028] Such as Figure 1-4 As shown, a magnetic levitation 3D printing moon lamp, including:

[0029] The 3D printing sphere 1 is a hollow structure with an opening at its lower end, and the 3D printing material on its surface is a non-transparent light-transmitting material; the surface of the 3D printing sphere 1 is added with text, LOGO marks or pictures.

[0030] The acrylic cover 2 is located on the outside of the 3D printed sphere 1, and its function is to protect the entire suspension from external air flow and human touch, dust-proof and atmospheric in appearance; the lower end side wall of the acrylic cover 2 is provided with a The threading hole 11 through which the wires of the magnetic levitation base power adapter 9 pass.

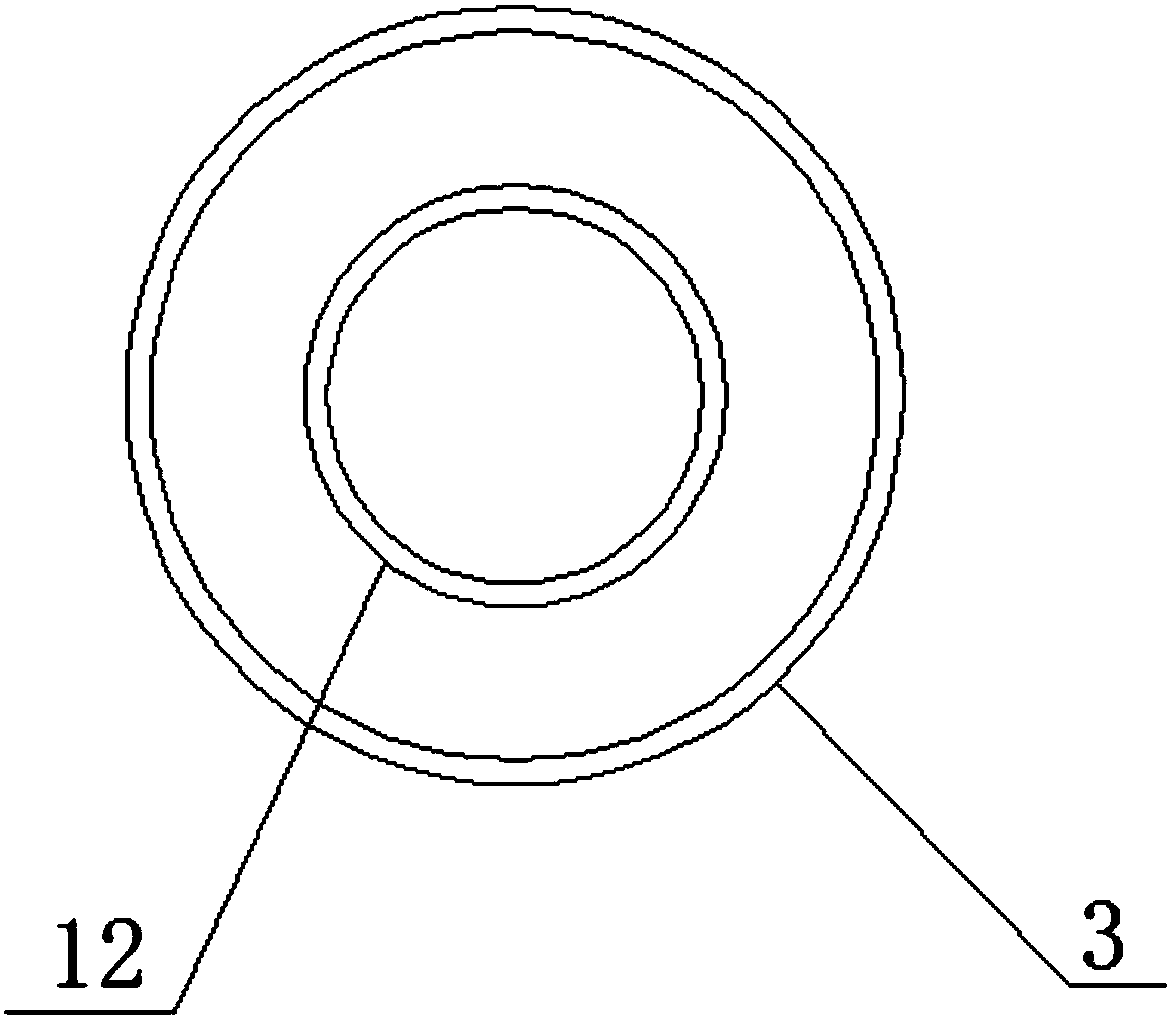

[0031] The 3D printed magnetic tray 3 is in the shape of an inverted hat as a whole, and is connected with the 3D printed sphere 1 to form a spherical shape, and its inner middle part is connected with a limiting ring 12; the 3D printed magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com