A method for initializing and controlling the absolute humidity sensor of a microwave oven

A technology of humidity sensor and absolute humidity, which is applied in the direction of household stove/stove, electric heating fuel, lighting and heating equipment, etc. It can solve the problems of cooking performance error, false alarm, wrong initial standard value, etc., and achieve convenient and fast use, Strong practicality and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

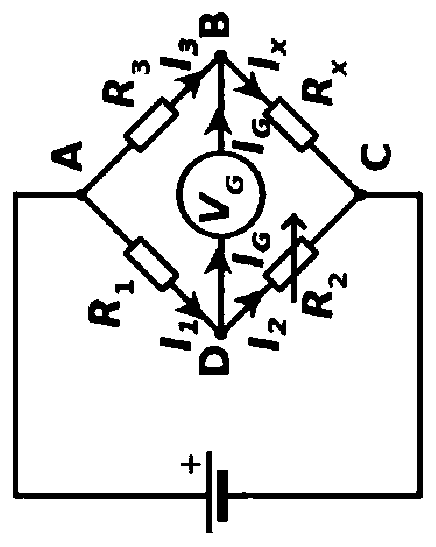

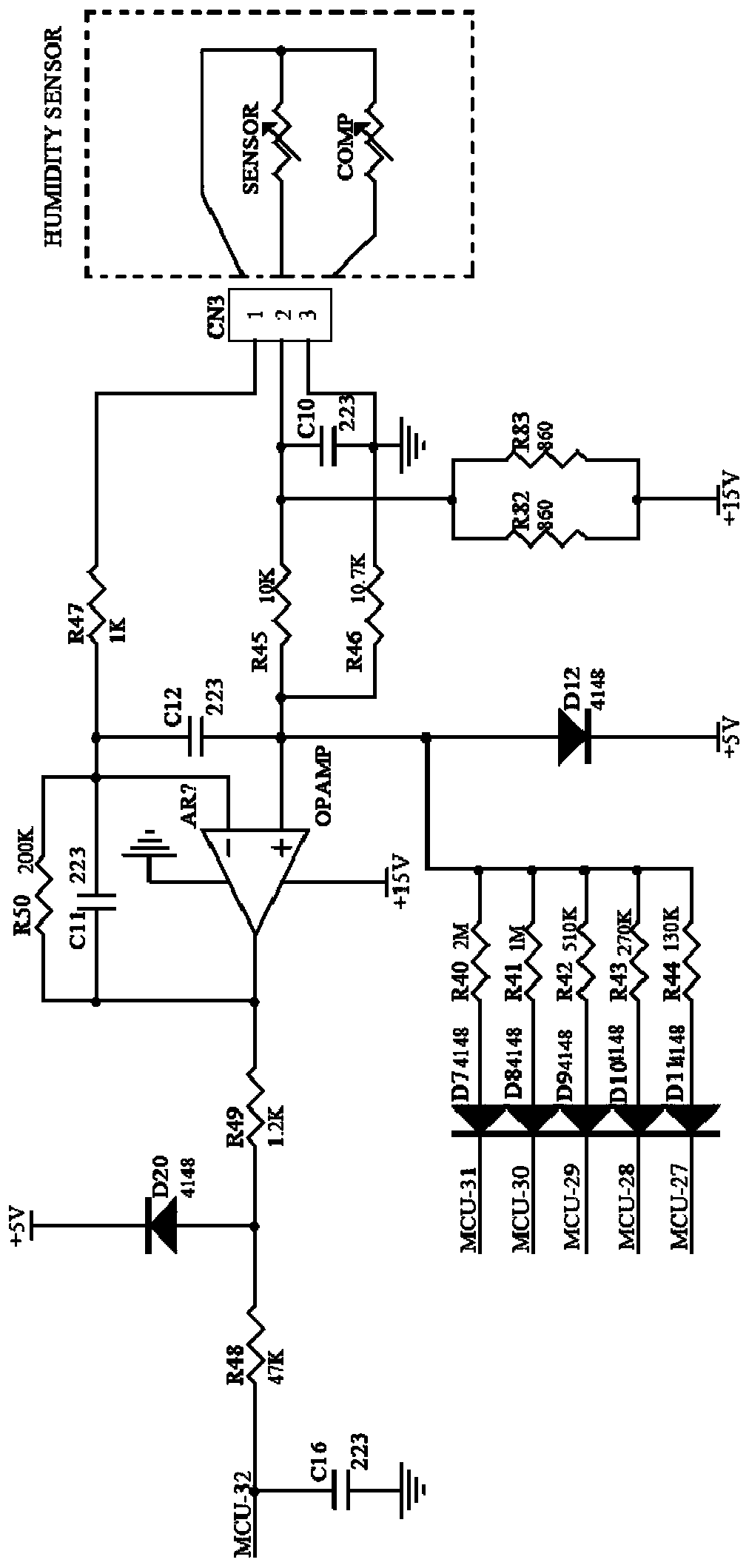

[0035] see image 3 , The initialization control method of the absolute humidity sensor of the microwave oven includes a Wheatstone bridge circuit arranged on the humidity sensor, and is characterized in that five parallel resistors are arranged in the Wheatstone bridge circuit.

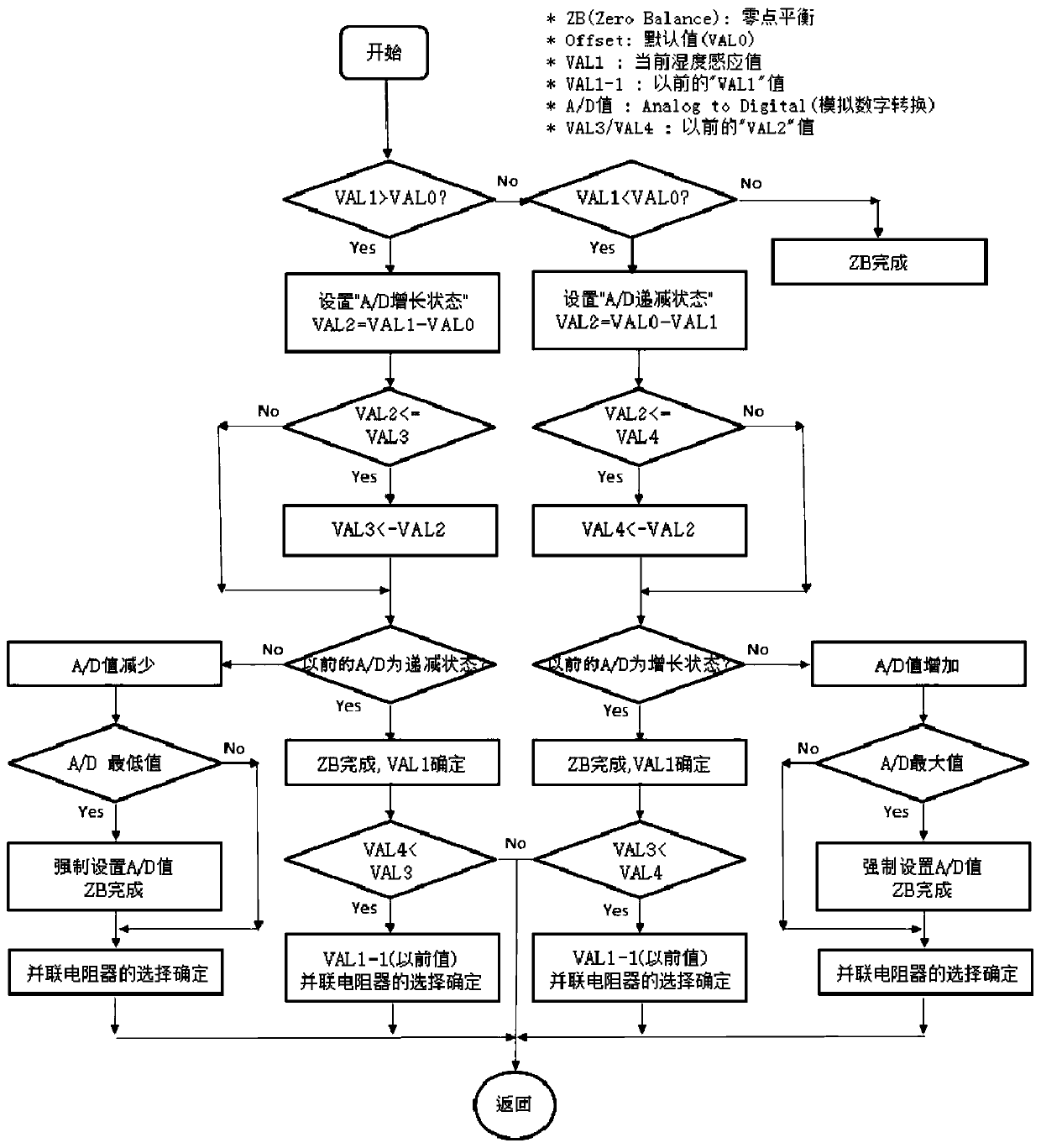

[0036] When the humidity sensor starts to cook in the microwave oven, first check whether the initialization is completed. If it is not initialized, consider the characteristics of the absolute humidity sensor and the best standard value of the change value of the humidity sensor value as the standard, select the parallel resistance value in turn, and then find out The best initial balance value, this is the first initialization method.

[0037] When selecting a parallel resistance, compare the current humidity sensor voltage value with the previous humidity sensor voltage va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com