Furnace kiln cooling wall image information collection unit and device and cooling wall detection method

A technology of image information and acquisition unit, applied in the field of detection, can solve the problem of inconvenient detection of cooling walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

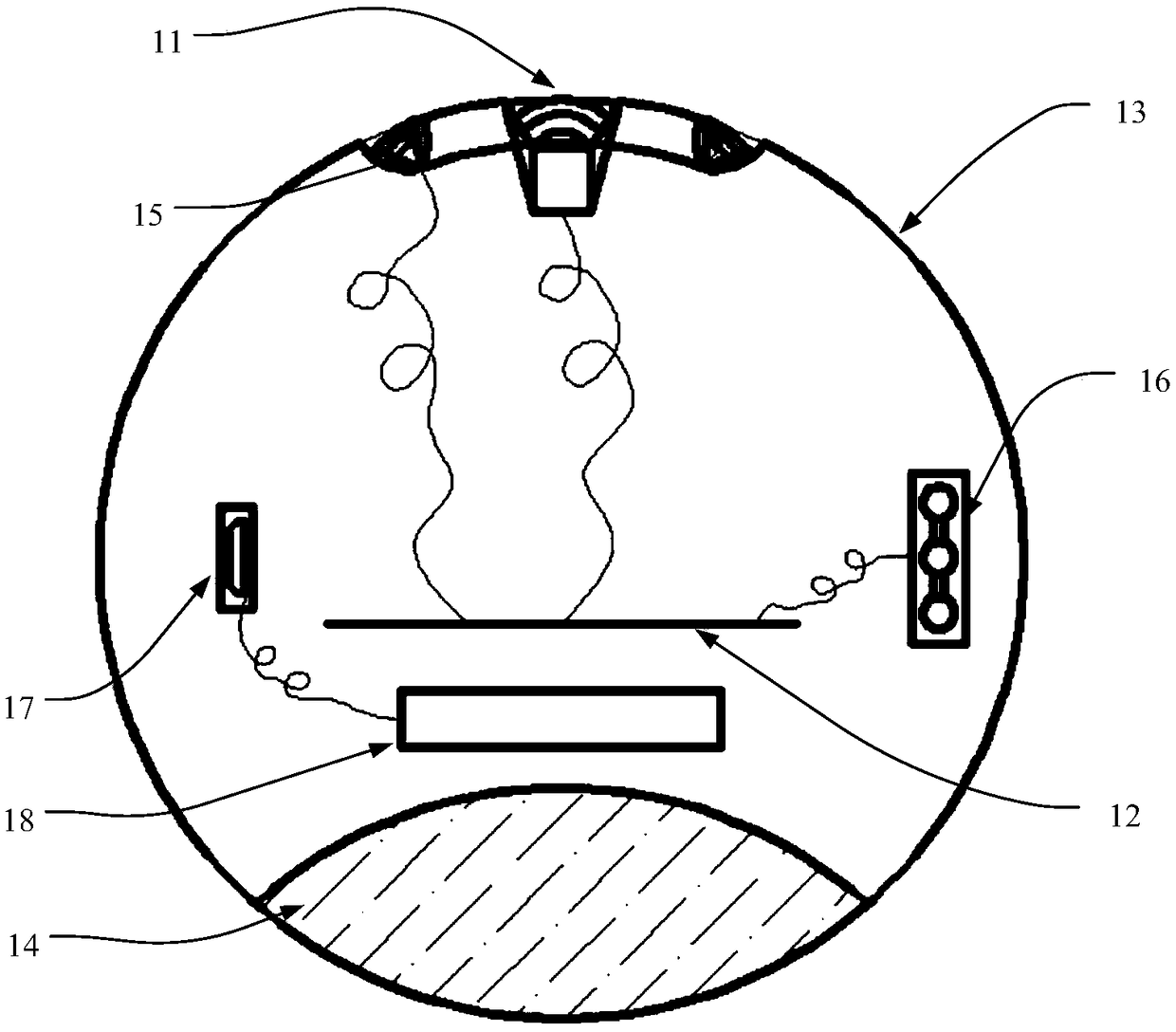

[0051] See figure 1 with figure 2 One side of the housing 13 of the acquisition unit is provided with a camera 11, and a supplementary light 15 is also provided for the camera 11 accordingly. The camera 11 and the supplementary light 15 are both connected to the integrated circuit board 12 and integrated on the integrated circuit board 12. There is a data storage module. The camera 11 collects the image information of the cooling stave and stores the image information on the integrated circuit board 12. The collection unit also includes a switch 16, an interface 17 and a battery 18. The switch 16 includes on, off and reset keys. Press the open key before use, then turn on the acquisition unit, then press the reset key and reset the data of the data storage module. After the acquisition unit is captured, press the key to complete data collection. The interface 17 is used to read the image information collected offline. According to actual working conditions, the interface 17 is ...

Embodiment 2

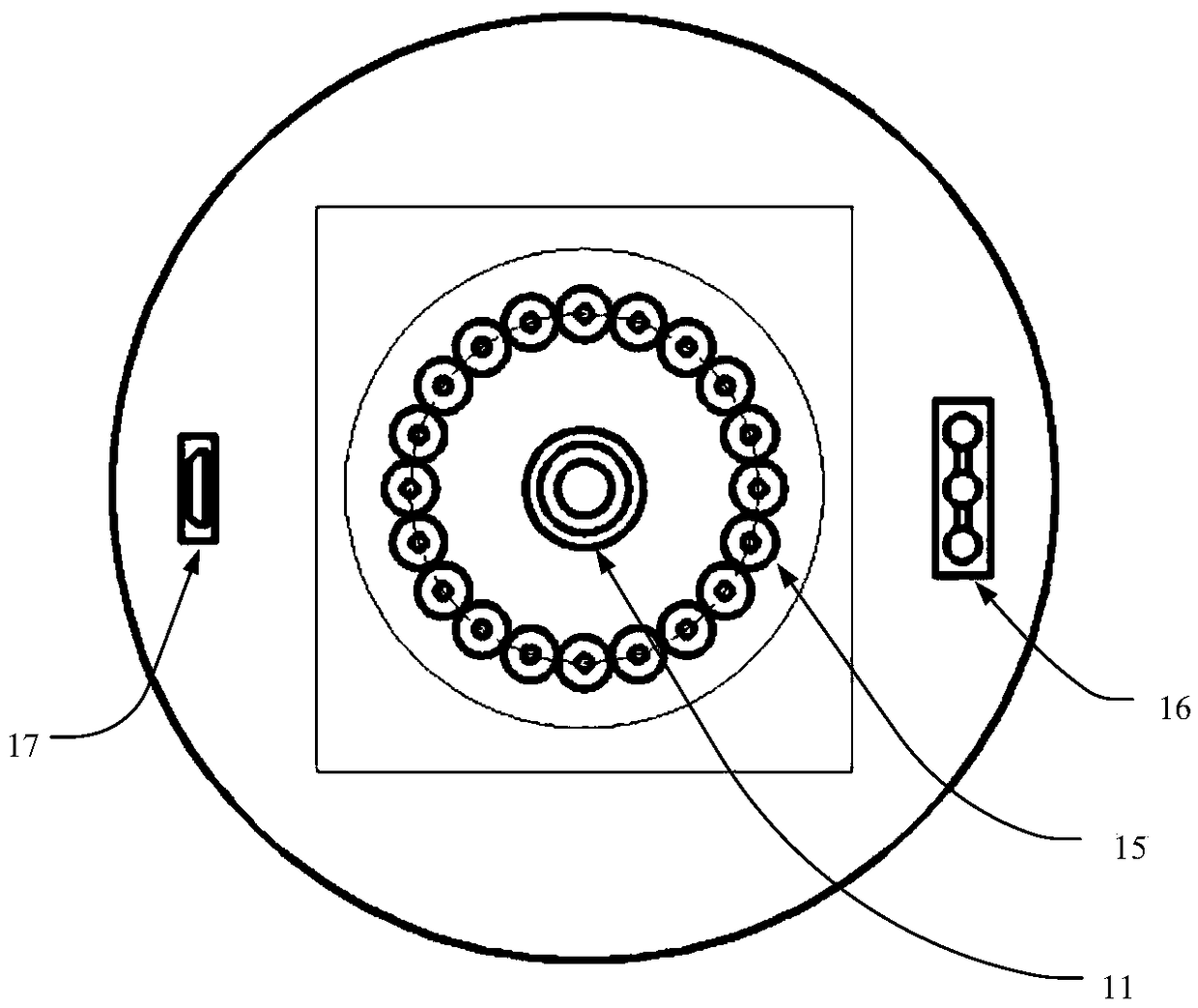

[0053] See image 3 with Figure 4 The number of cameras 14 can be selected as 3, 4,..., N, where N is a positive integer. In this embodiment, the number of cameras 11 is taken as an example for illustration, which is convenient for those skilled in the art to understand the technical solution, and it is not essential The limitation is that the three cameras 11 are arranged in a "equal triangle" arrangement. With this solution, the angle of view taken by the camera is increased, achieving the purpose of collecting image information at a wide angle. Multiple cameras 11 collect image information of the same area, increasing image information The signal clarity reduces image noise or distortion. Correspondingly, the light supplement lamps 15 are arranged in a "ring" shape around the equilateral triangle to increase the light supplement effect. Further, the inside of the shell 13 is hollow and can be filled with inert gas, which reduces internal pressure fluctuations caused by chan...

Embodiment 3

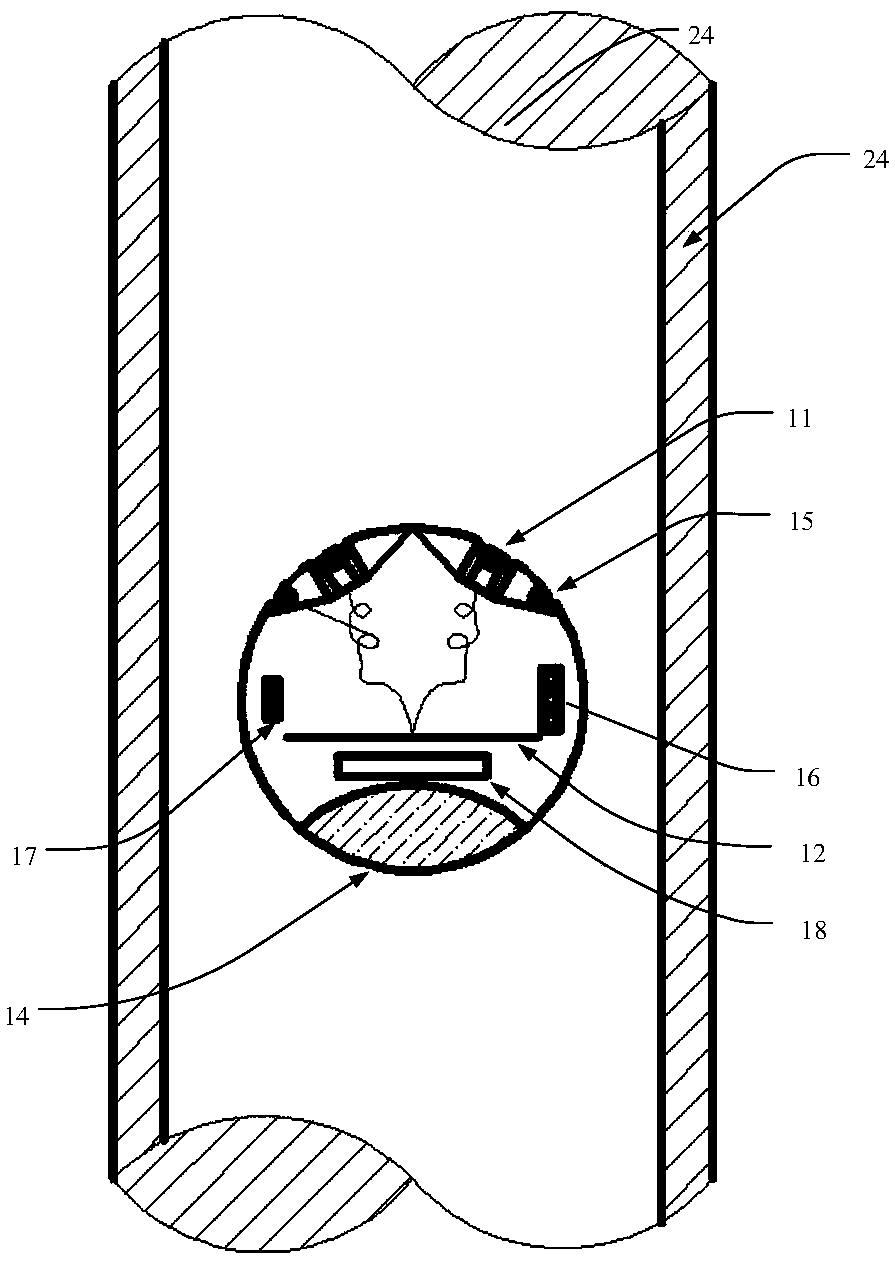

[0055] See Figure 5 The cooling channel includes at least a first valve 21 for opening or closing the cooling channel and a second valve 22 for releasing the image information acquisition unit of the kiln stave. The first valve 21 is a two-way valve The second valve 22 is a three-way valve. The second valve 22 includes a first interface for communicating with the cooling channel, a second interface, and a second interface for releasing the image information collection unit of the kiln stave. Three ports, specifically, the second valve is a T-shaped three-way valve.

[0056] First close the first valve 21, open the first port (water inlet) and the second port (water outlet) of the second valve 22; turn on the switch of the collection unit, put the collection unit into the third port, and turn the second valve 22 on Pipe; then open the first valve 21, the water supply pipe 23 provides cooling liquid, under the action of the cooling liquid and buoyancy, the collection unit moves al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com