Power equipment abnormality monitoring system and method based on multi-vision

A technology for power equipment and abnormal monitoring, which is applied to components of TV systems, radiation pyrometry, components of color TV, etc., can solve the problems of low degree of automation, missed detection, poor real-time performance, etc. The effect of avoiding failure, great economic value and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

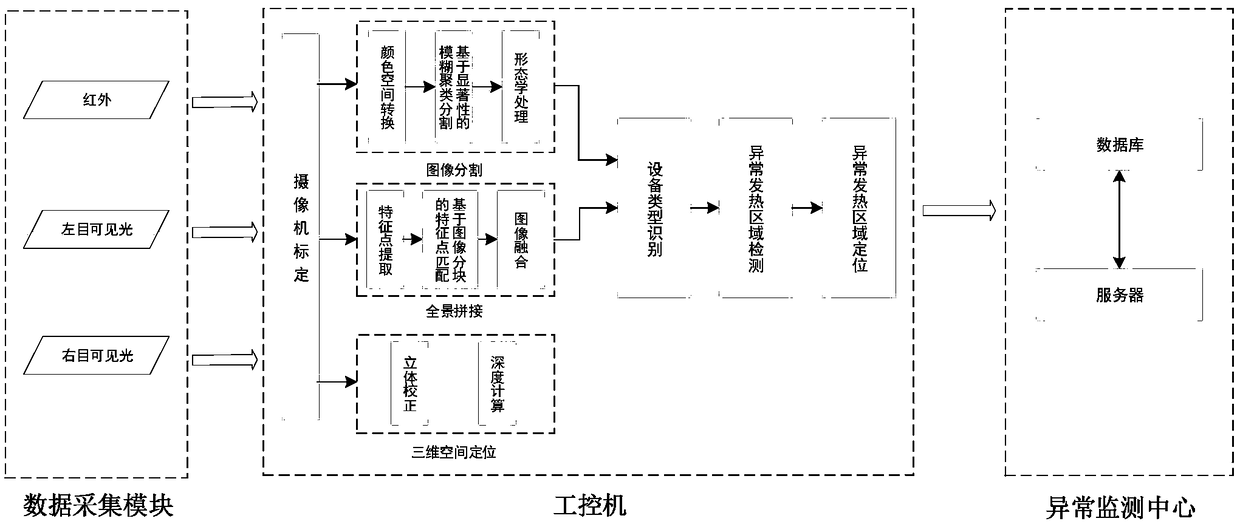

[0072] like figure 1 As shown, a multi-eye vision-based power equipment abnormality monitoring system provided by the present invention includes a data acquisition device, an industrial computer, and an abnormality monitoring center; the data acquisition device includes an infrared camera for collecting infrared images of the area where the power equipment is located and a collection The left-eye visible light camera and the right-eye visible light camera of the visible light image of the area where the power equipment is located; the industrial computer analyzes and processes the infrared image and the visible light image, detects the abnormal heating area of the power equipment and locates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com