Multifunctional pipeline stress testing device

A testing device, a multi-functional technology, applied in the direction of measuring device, using stable shear force to test material strength, using stable tension/pressure to test material strength, etc., can solve the problem that the stress test position cannot be flexibly adjusted, etc. problems, to achieve the effect of improving overall stability, improving efficiency, and solving single test functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

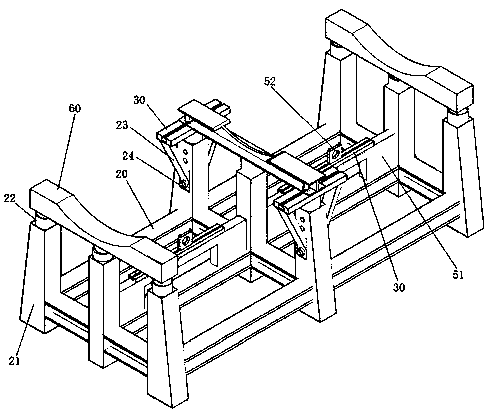

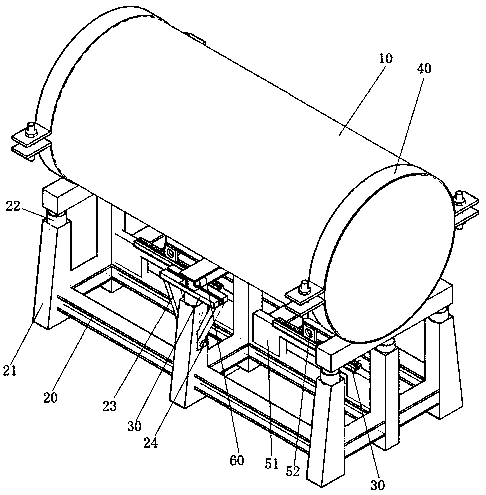

[0027] Such as figure 1 and as figure 2 As shown, the present invention provides a kind of multi-functional pipeline stress testing device, is provided with frame 20, is provided with fixing part 60 on frame 20, and fixing part 60 is arranged on the two ends of frame 20 and between two ends position, the fixing part 60 supports and fixes the pipeline 10 . The fixing part 60 is provided with an arc structure matching with the pipe 10 , and the arc structure improves the fit between the fixing part 60 and the pipe 10 .

[0028] Such as figure 1 As shown, a support member 21 is provided on the frame 20, and a lifting device 22 is provided on the support member 21. The lifting device 22 is a hydraulic lifting device 22, and the support is connected with the fixed part 60 through the lifting device 22, and the fixed part 60 is controlled to rise or fall. decline.

[0029] In this embodiment, three support members 21 are arranged side by side at or between both ends of the fram...

Embodiment 2

[0036]In this embodiment, three support members 21 arranged between the two ends of the frame 20 are provided side by side, and the support members 21 arranged on both sides are connected with the connecting rod 23, and the connecting rod 23 is connected with a slide rail 30, and the slide rail 30 can be connected with the lifting device 22 and can be displaced relative to the supporting member 21 under the action of the lifting device 22 .

[0037] After the slide rail 30 is displaced, the connecting rod 23 is fixedly connected to the support member 21 through the positioning screw 24 , so as to fix the position of the slide rail 30 relative to the support member 21 . The fixed part 60 is slidably connected to the slide rail 30 , the fixed part 60 can slide relative to the slide rail 30 , and the position of the fixed part 60 relative to the pipeline 10 can be adjusted to provide conditions for realizing the shear force test at different positions on the pipeline 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com