Method for correcting delay link of calorimetric process of calorimeter by utilizing transfer function

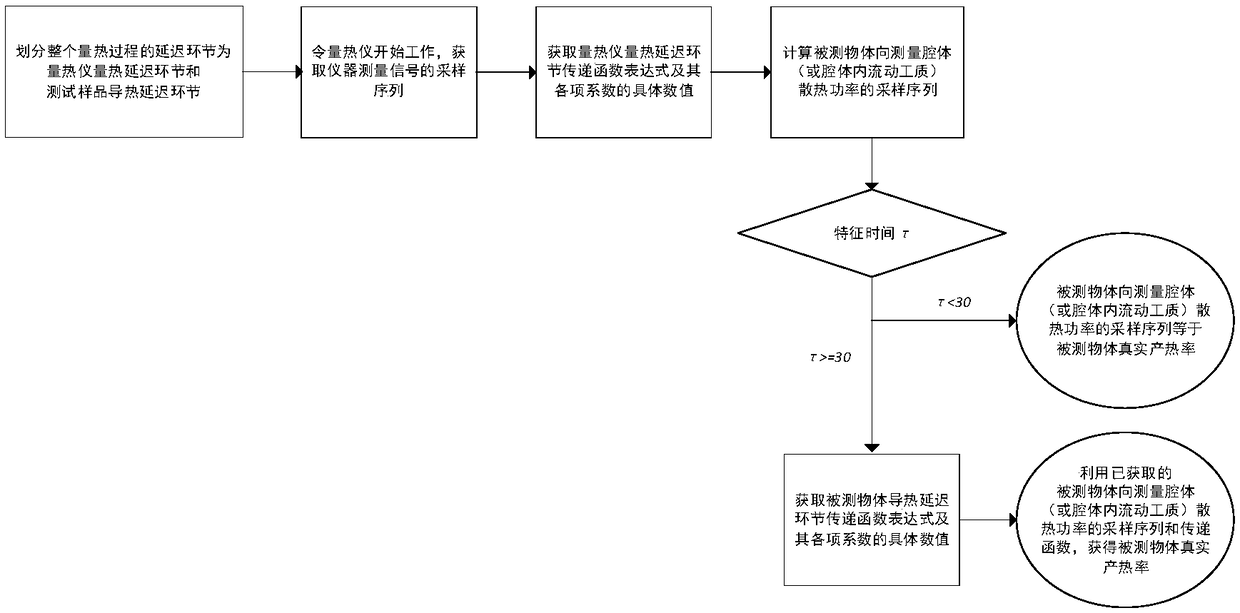

A technology of transfer function and process delay, applied in the field of calorimeter, can solve the problem that the influence of delay link cannot be completely eliminated, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

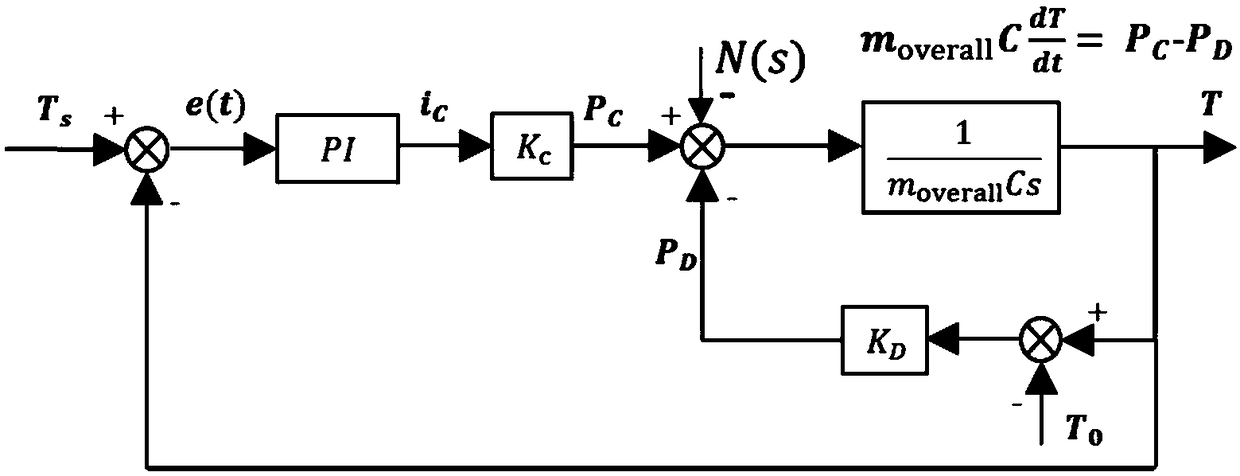

Method used

Image

Examples

Embodiment 1

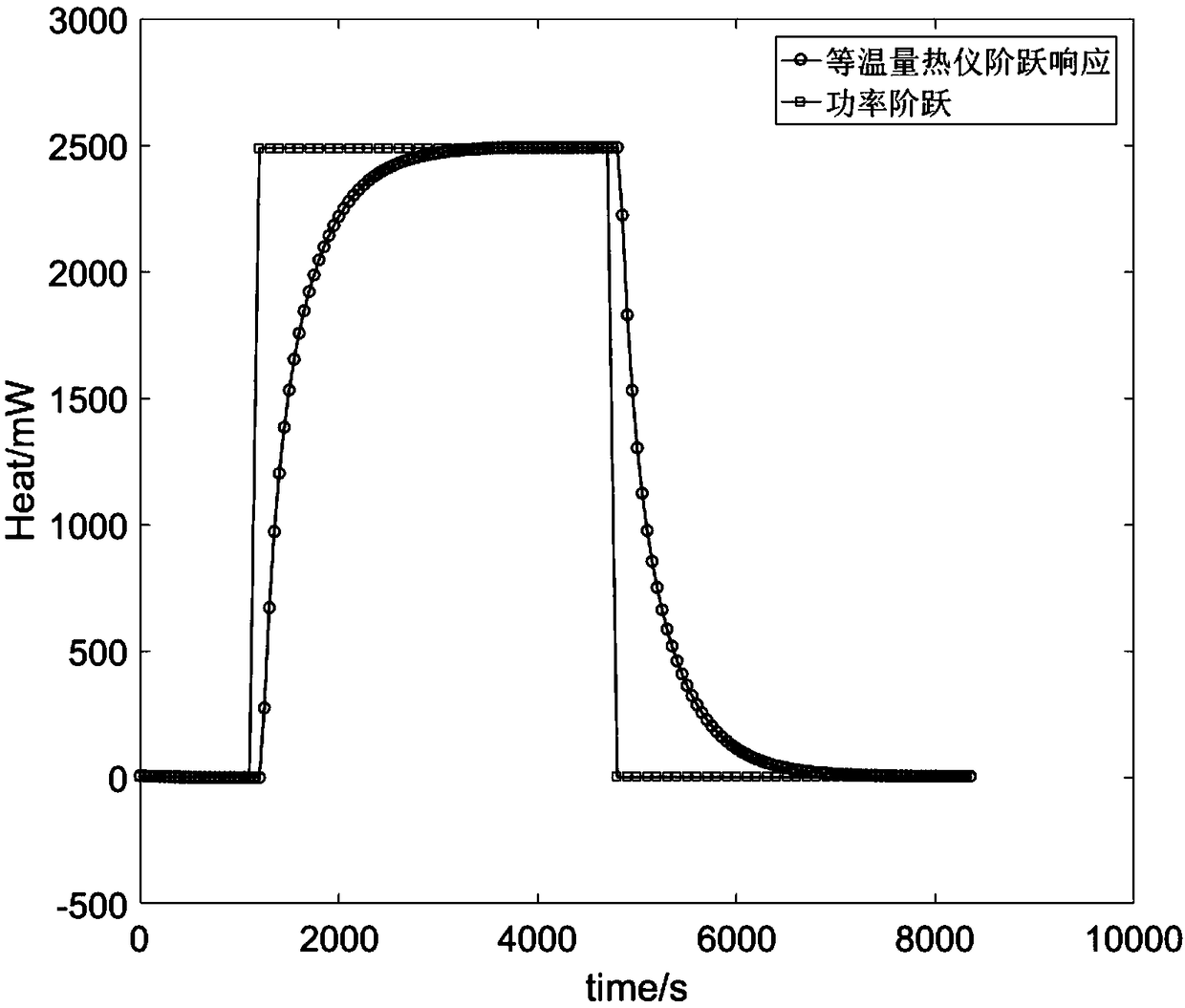

[0063] Taking the calibration resistance as the measured object, the step response correction of an isothermal calorimeter is used as embodiment 1;

[0064] 1) Select the isothermal calorimeter IBC-18650 of THT (Thermal Hazard Technology) company, select a cylindrical aluminum calibration resistor with a cross-sectional diameter of 26mm and a height of 65mm as the measured object, and take the calorimeter’s calorimetric process The delay link is divided into the heat delay link of the calorimeter and the heat conduction delay link of the measured object.

[0065] 2) Put the measured object selected in step 1) into the calorimeter, and the calorimeter starts to work and generates a continuous instrument measurement signal P c =P c (t), where t is a time-domain variable. The calorimeter samples the signal, the sampling interval is Δt, and the discrete instrument measurement signal sequence is obtained as P c (k)=P c (t k ), where k is a non-negative integer, and t k = kΔt....

Embodiment 2

[0085] Taking a 18650 battery as the measured object, the calorimetric correction of 0.5C, 1C, and 2C rate discharge at 25°C is used as Example 2;

[0086] 1) Select an isothermal calorimeter identical to that in Example 1, choose a 18650 battery with a cross-sectional outer diameter of 18 mm, an inner diameter of 2 mm, and a height of 65 mm as the measured object, and the delay link of the calorimetric process of the calorimeter It is divided into the heat delay link of the calorimeter and the heat conduction delay link of the measured object.

[0087] 2) Put the measured object selected in step 1) into the calorimeter, and the calorimeter starts to work and generates a continuous instrument measurement signal P c =P c (t), where t is a time-domain variable. The calorimeter samples the signal, the sampling interval is Δt, and the discrete instrument measurement signal sequence is obtained as P c (k)=P c (t k ), where k is a non-negative integer, and t k = kΔt.

[0088]...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap