Electronic tag that monitors bolt looseness

An electronic label and bolt loosening technology, which is applied to record carriers, instruments, computing and other directions used by machines, can solve the problems of difficult construction, loss of life and property, and high processing costs, so as to improve labor efficiency, prevent oil pollution, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

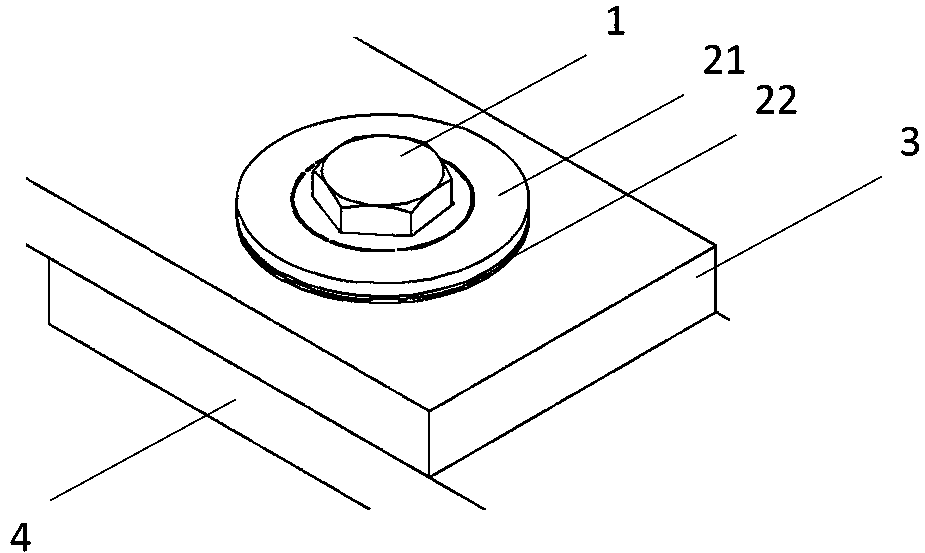

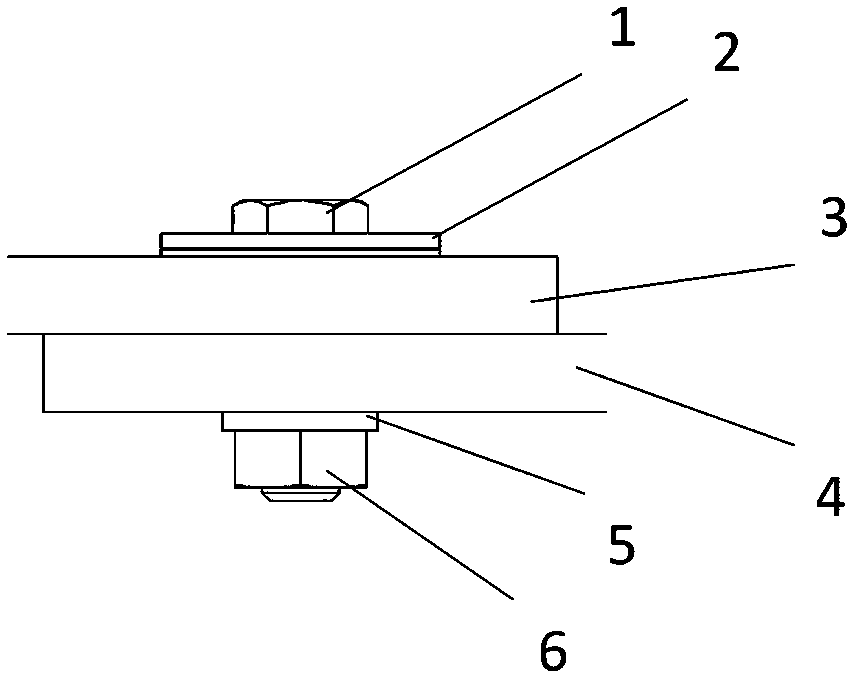

[0037] Such as Figure 4 As shown, an electronic tag 2 for monitoring bolt looseness mainly includes an electronic tag body 21 and an electronic tag base 22 .

[0038] The electronic tag body 21 includes a counterbore 212 , a non-fixed part 218 , a fragile area 211 , a fixed part 217 and a radio frequency circuit.

[0039] Preferably, the electronic tag main body 21 is made of ABS thermoplastic polymer material.

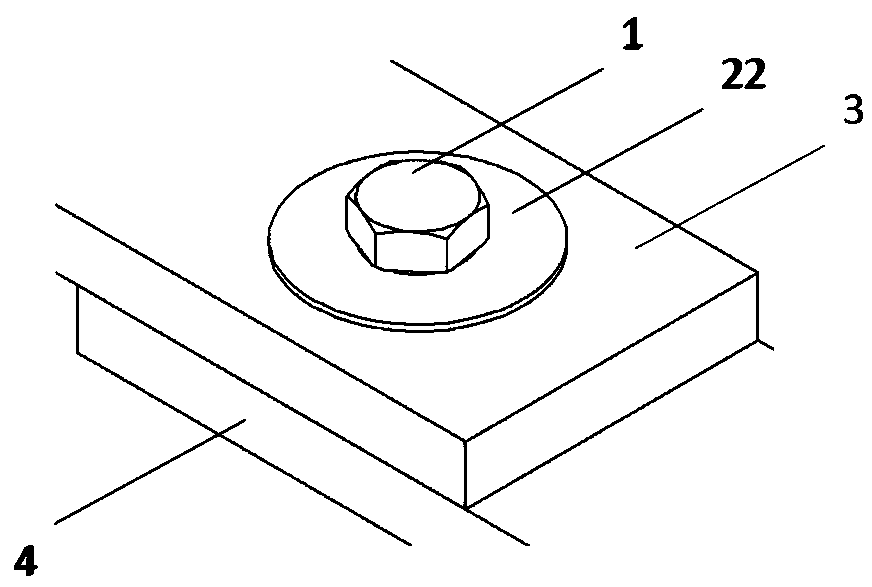

[0040] Such as figure 1 As shown, the external dimensions of the counterbore 212 are determined according to the external dimensions of the bolt head, so as to ensure that when the bolt 1 rotates, the non-fixed part 218 is driven to rotate under force.

[0041] Such as Image 6 As shown, the radio frequency circuit includes a radio frequency chip 213 , an antenna 214 and an anti-ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com