A kind of ferroelectric thin film material device and its preparation method

A ferroelectric thin film and device technology, applied in the field of ferroelectric thin film material devices and their preparation, to achieve the effects of superior ferroelectric photovoltaic performance, good ferroelectricity, and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

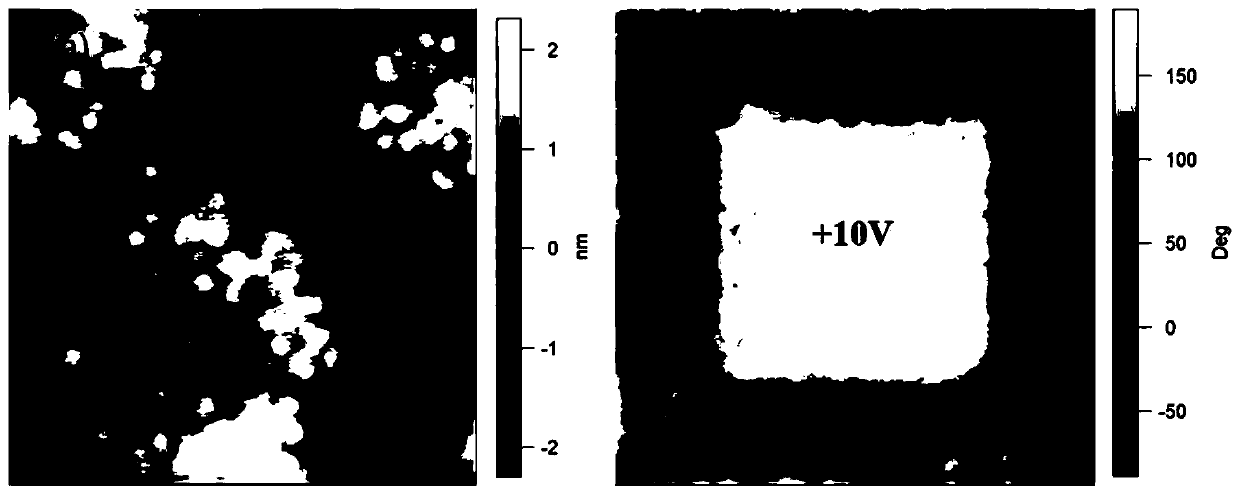

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

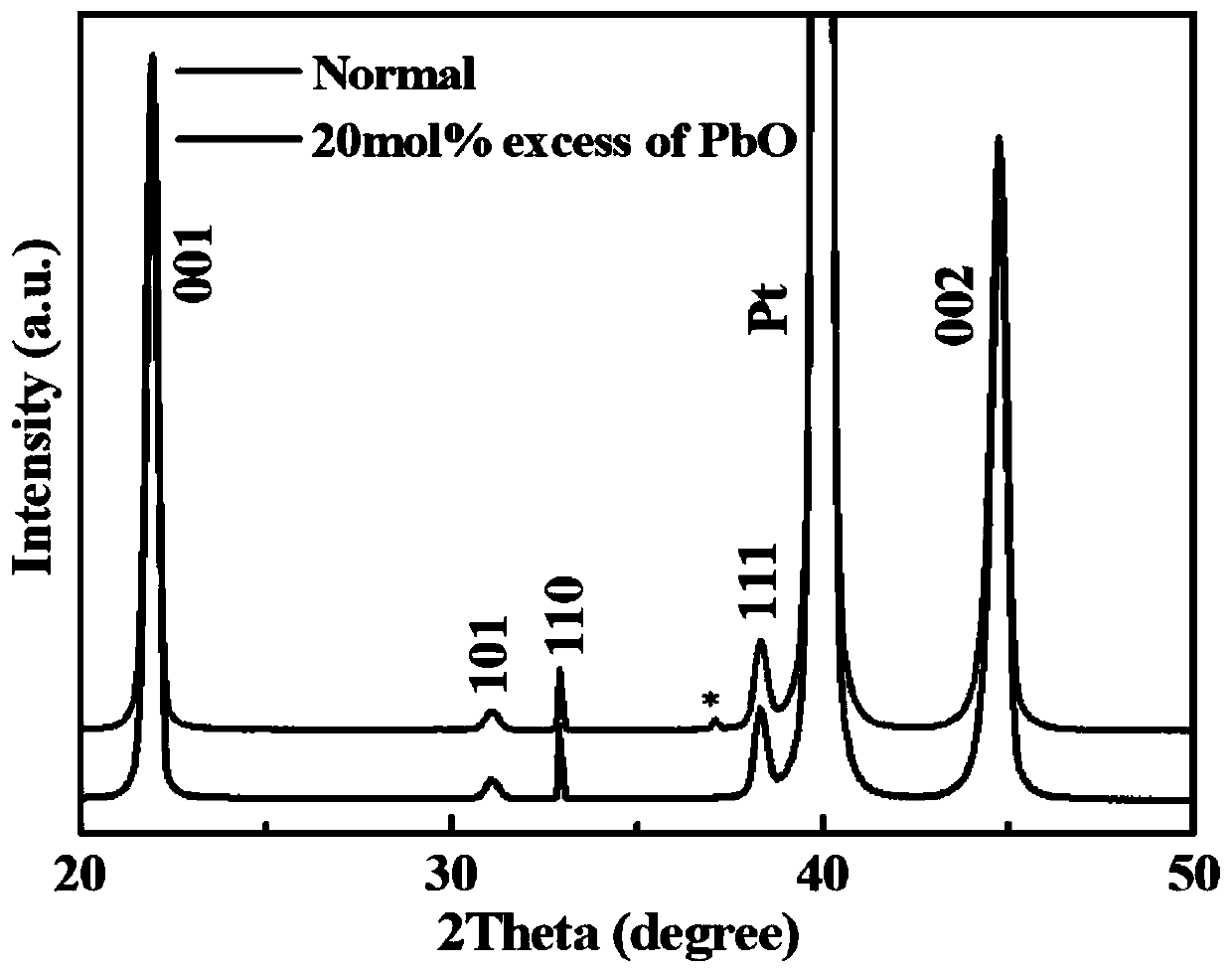

Embodiment 1

[0024] The preparation method of the ferroelectric thin film material device of the present invention comprises the following steps:

[0025] Step 1: Preparation of ferroelectric material lead zirconate titanate Pb(Zr 0.52 Ti 0.48 )O 3 (hereinafter referred to as PLZT) sol.

[0026] In this embodiment, the molar concentration of the PZT sol is 0.25 mol / L, and the volume is 100 mL. The preparation raw materials of PZT sol are shown in Table 1:

[0027] Table 1 Preparation materials of PZT sol

[0028] Drug Name molecular weight drug purity Experimental ratio stoichiometric number Weighing mass Lead acetate trihydrate 379.33 0.995 1.2 0.03 11.43 Zirconium n-propoxide 327.57 0.7 0.52 0.013 6.09 Titanium tetraisopropoxide 284.22 0.95 0.48 0.012 3.59

[0029] The specific preparation steps are as follows:

[0030] 1) Weigh the required raw materials according to the weighing quality in Table 1;

[0031] 2) adding lead ace...

Embodiment 2

[0043] This example is basically the same as Example 1, except that in the preparation raw materials of PZT sol, the lead in Example 1 is excessive by 20%, but the lead in this example is not excessive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| open-circuit voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com