A preparation method of a shielded gate power device

A technology for power devices and shielded gates, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of large static power loss, large switching power loss of shielded gate power MOSFETs, and large on-state resistance, etc. The effect of improving reverse withstand voltage, small on-state resistance and reducing capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

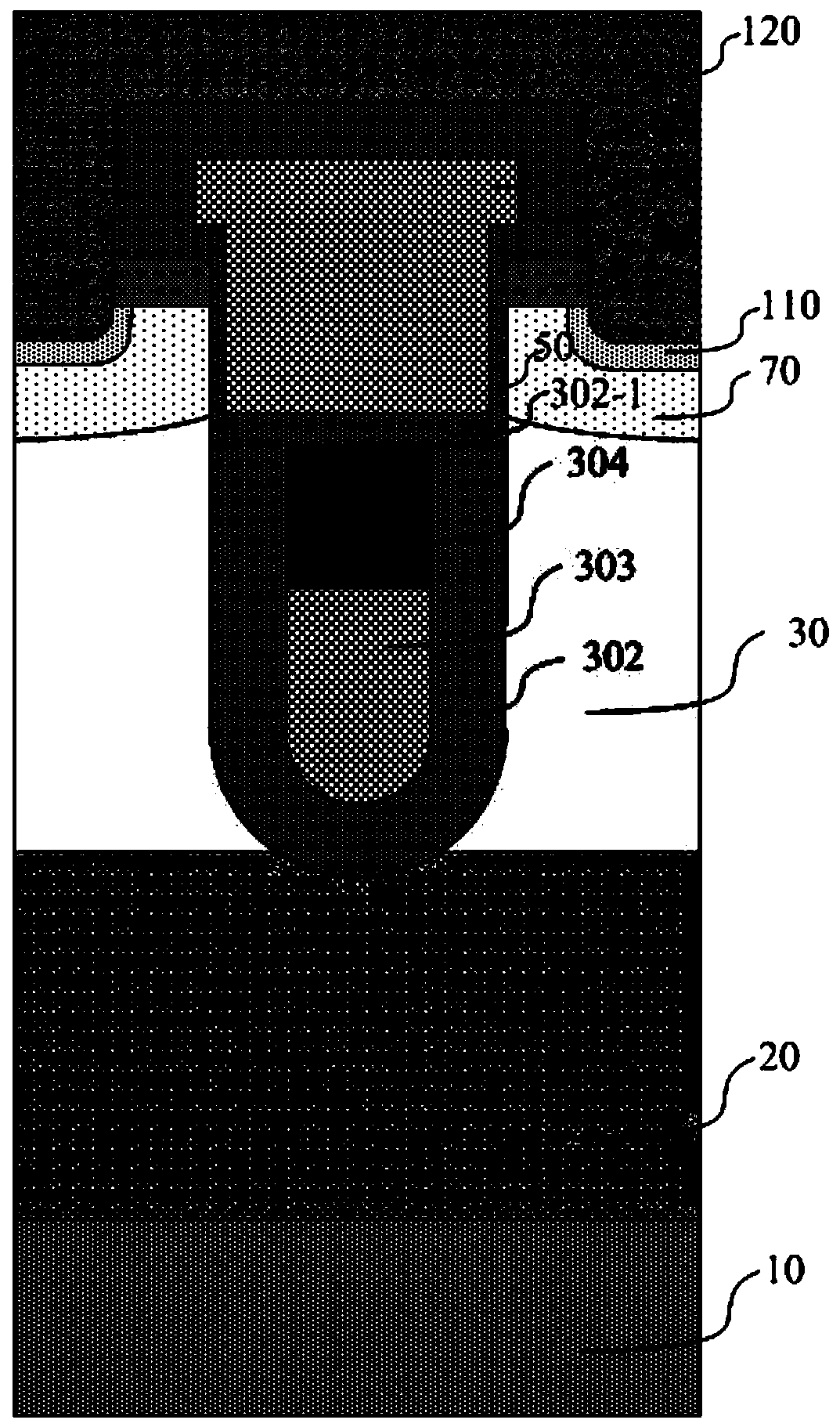

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] As shown in the figure, a method for manufacturing a shielded gate power device includes the following steps:

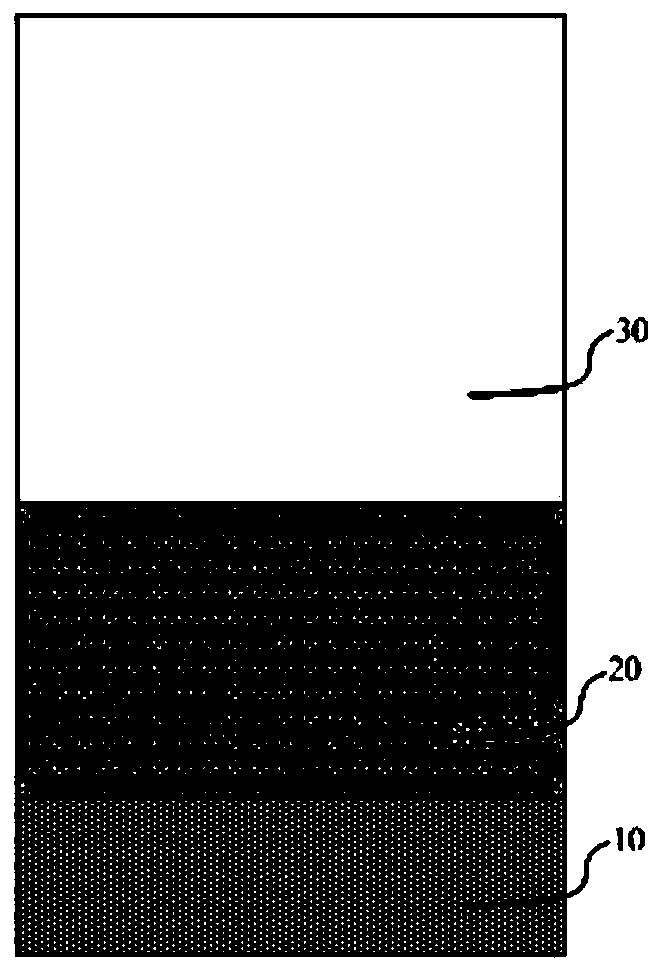

[0027] Step 1. Provide an N-type heavily doped semiconductor substrate (10), grow a first epitaxial layer and a second epitaxial layer on the N-type heavily doped semiconductor substrate (10), and the first epitaxial layer is The low resistance layer (20), and the second epitaxial layer is a high resistance layer (30). The gate oxide extends vertically toward the drain, and the Resurf technology is used to optimize the lateral electric field distribution of the upper high-resistance layer (30) to improve the reverse withstand voltage of the device, and the lower layer is epitaxy to reduce the device’s On-state resistance;

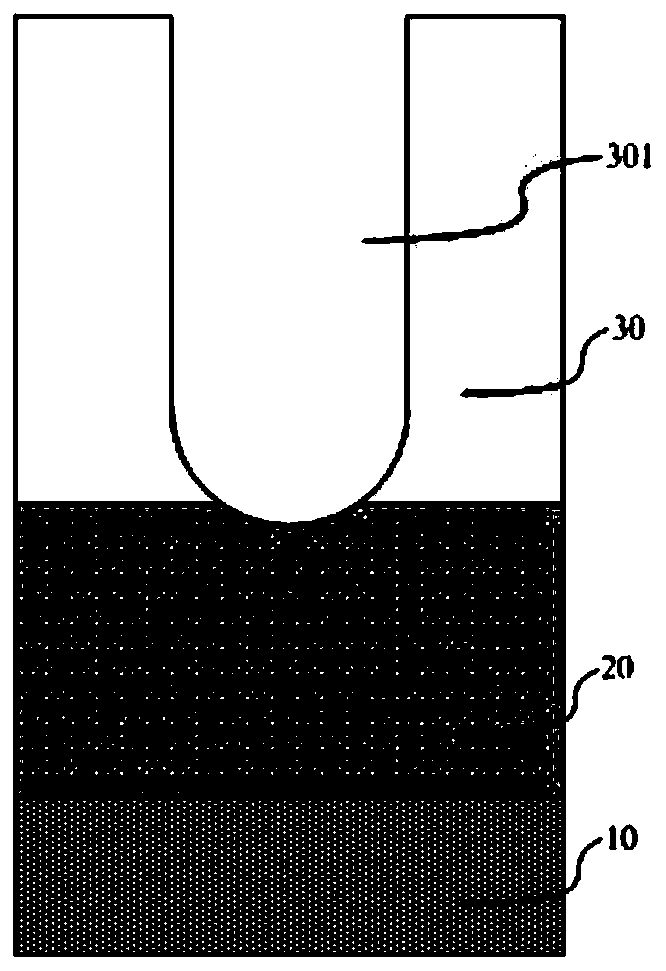

[0028] Step 2, etching the high-resistance layer (30) to form a trench (301), the bottom of the trench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com