Active overvoltage protection gap with plug-and-pull function in gas environment

A gas environment and protection gap technology, applied to overvoltage arresters, circuits, spark gaps, etc. that apply spark gaps, can solve problems such as inability to reduce the pressure ratio of overvoltage protection gaps, surface pollution of flashover rods along the surface, and reduced safety. , to achieve strong trigger carrier release capability, fast lightning overvoltage response characteristics, and reduce the effect of pulse breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

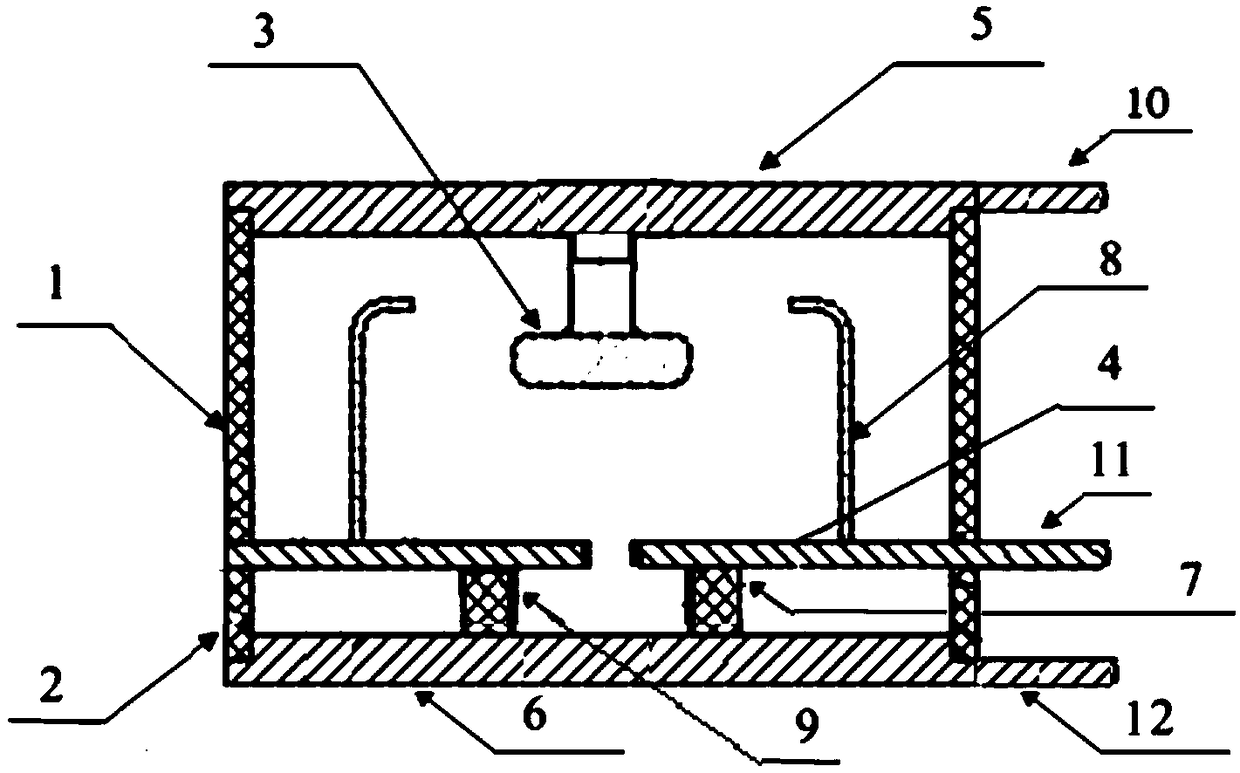

[0018] Example 1, see figure 1 , the present invention includes the upper insulating shell 1, the lower insulating shell 2, the upper end flange 5 and the lower end flange 6, and the air pressure is 10 0 ~10 3 or 10 4 ~5×10 5 The cavity of Pa is provided with an upper electrode 3 installed on the upper flange 5 in the cavity, and a ring-shaped intermediate electrode 4 with a thickness of 3-6mm is installed between the upper insulating shell 1 and the lower insulating shell 2, and the upper The main discharge gap is formed between the electrode 3 and the ring-shaped middle electrode 4. Between the lower end flange 6 and the ring-shaped middle electrode 4, an inner diameter of 5-12mm, a ring width of 4-10mm, and a height of 5-15mm are installed for insulation and isolation. The annular surface flashover insulating dielectric material 7, the surface discharge trigger forming the active overvoltage protection gap between the lower flange 6, the annular surface flashover insulat...

Embodiment 2

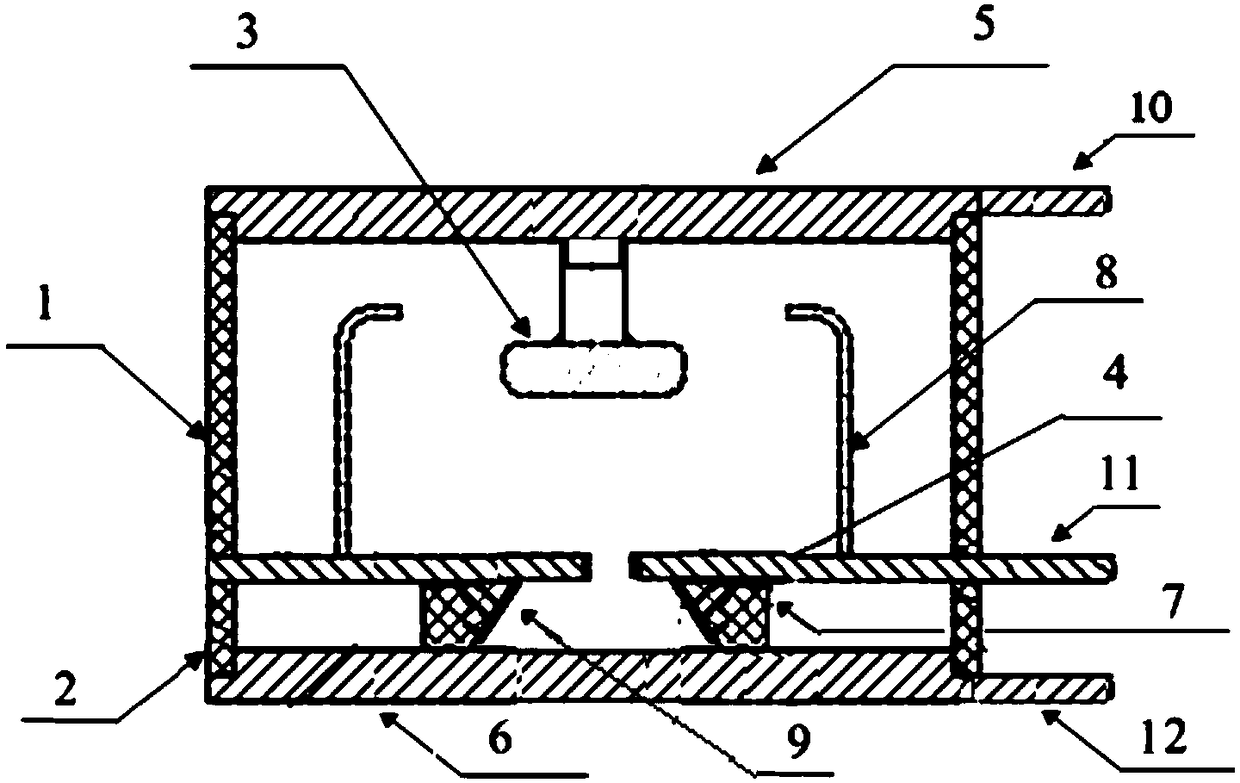

[0019] Example 2, see figure 2 , the lower part of the annular surface discharge insulating dielectric material 7 of the present invention is cylindrical, and the inner side of the upper cylinder is trapezoidal, and the contact between the annular surface discharge insulating dielectric material 7 and the upper surface of the annular intermediate electrode 4 and the lower flange trigger electrode 6 A surface flashover discharge interface 9 is formed between the points, and the acute angle between the surface flashover discharge interface 9 and the upper surface of the lower flange 6 is 30°-70°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com