Road hedge pruning greening structure and its construction method

A hedge trimming and construction method technology, applied in the direction of hedge trimming equipment, etc., can solve the problems of low efficiency, large operator physical exertion, human injury, etc., achieve fast construction speed, improve trimming efficiency, save labor and labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

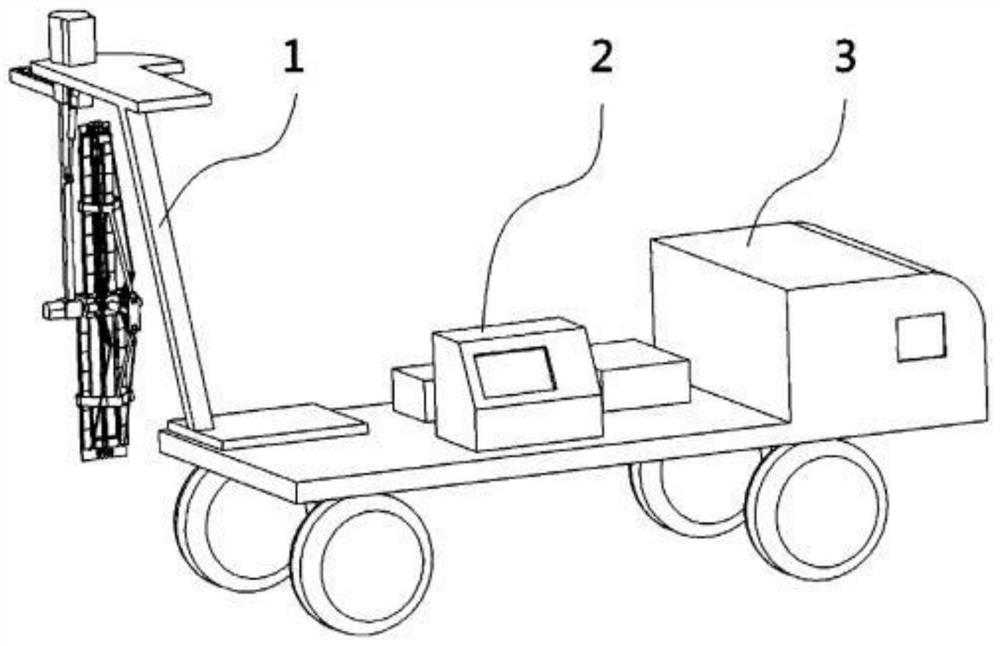

[0025] As shown in the figure, the road hedge pruning greening structure includes an engineering vehicle 3 on which a console 2 and a bracket 1 are installed; the console 2 is used to control the movement of electrical components in this embodiment.

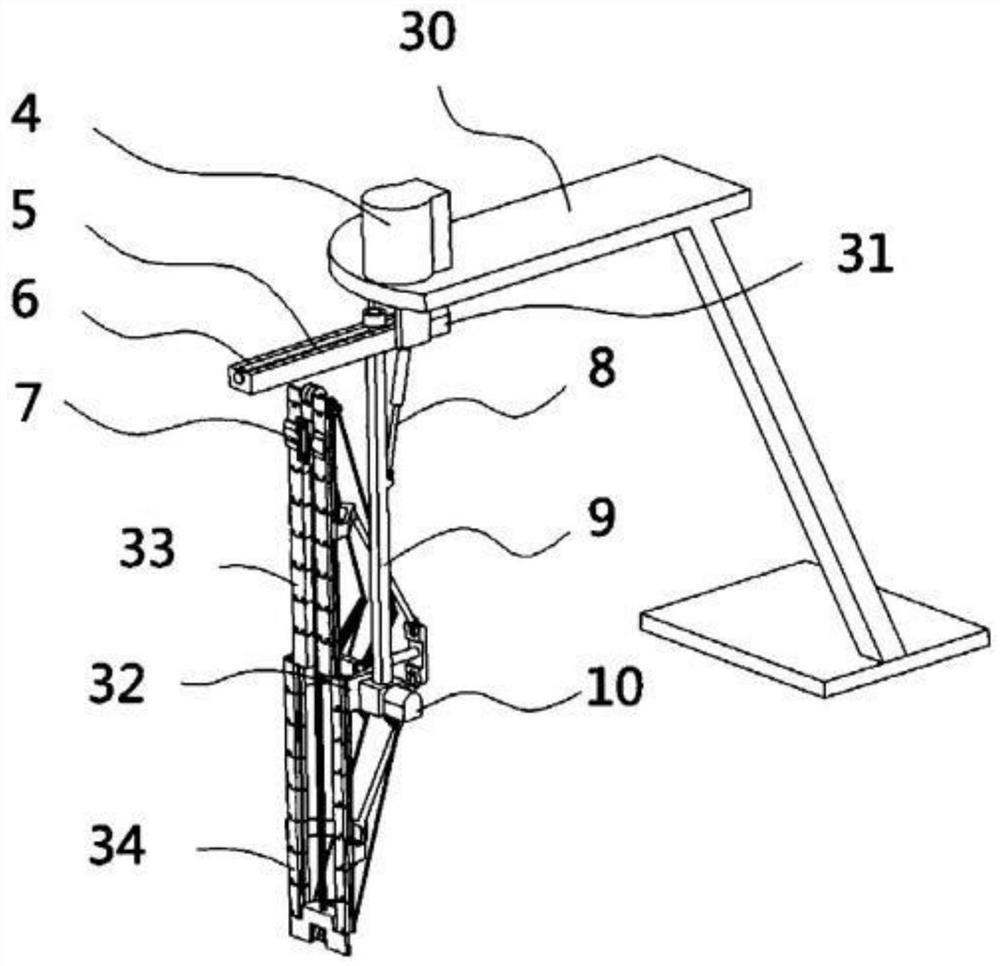

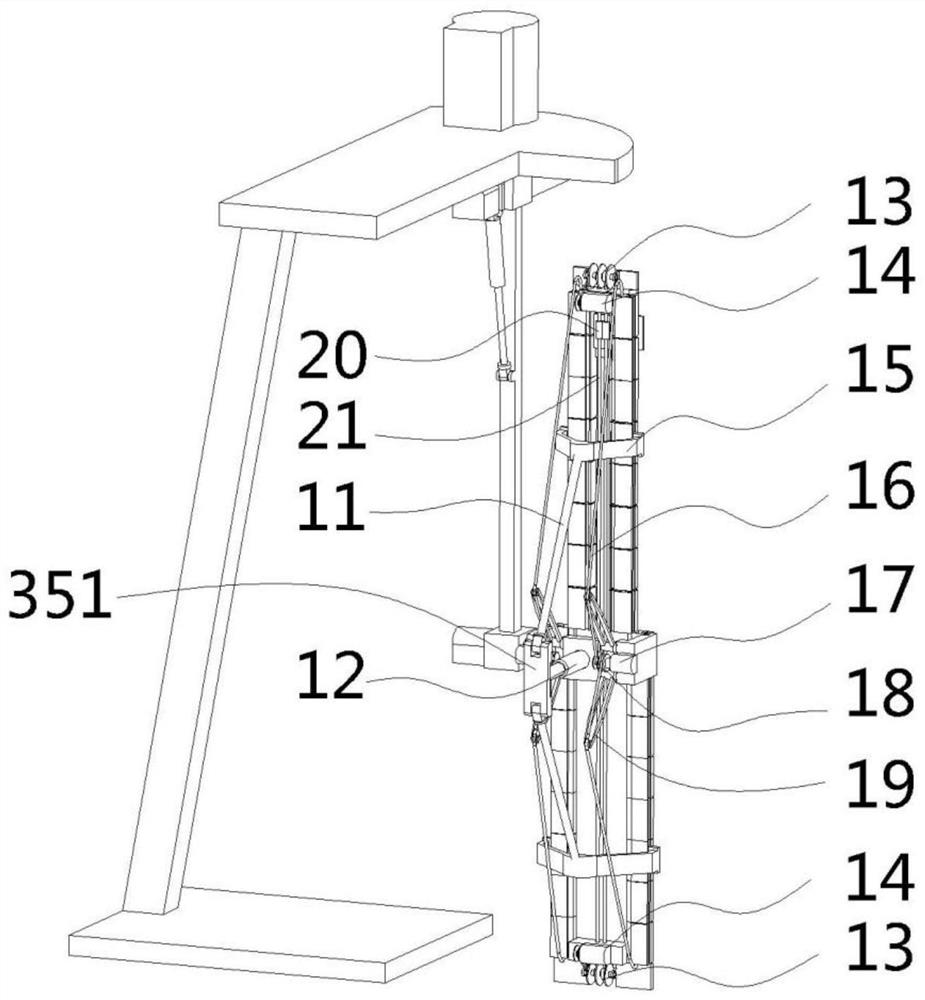

[0026] A top plate 30 is installed on the support 1, and a rotating arm 6 is installed below the top plate 30. The rotating arm 6 is driven to rotate by a motor one 4, and the motor one 4 is installed above the top plate 30. Two 31 drive the rotating feed screw 5, the feed screw 5 is equipped with a connecting arm 9, and the connecting arm 9 is equipped with an intermediate frame 32 driven by the motor three 10 to rotate. Motor two 31 drive feed screw rod 5 to rotate and make connecting arm 9 move back and forth and carry out deep or shallow pruning to hedge.

[0027] The both sides of intermediate frame 32 are equipped with track one 33 and track two 34 respectively, and described track one 33 and track two 34 all adopt a plural...

Embodiment 2

[0035] The road hedge pruning greening structure includes an engineering vehicle 3 on which a console 2 and a bracket 1 are installed; the console 2 is used to control the movement of electrical components in this embodiment.

[0036] A top plate 30 is installed on the support 1, and a rotating arm 6 is installed below the top plate 30. The rotating arm 6 is driven to rotate by a motor one 4, and the motor one 4 is installed above the top plate 30. Two 31 drive the rotating feed screw 5, the feed screw 5 is equipped with a connecting arm 9, and the connecting arm 9 is equipped with an intermediate frame 32 driven by the motor three 10 to rotate. Motor two 31 drive feed screw rod 5 to rotate and make connecting arm 9 move back and forth and carry out deep or shallow pruning to hedge.

[0037] The both sides of intermediate frame 32 are equipped with track one 33 and track two 34 respectively, and described track one 33 and track two 34 all adopt a plurality of plates 35 to be h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com