Tea frying machine

A tea frying machine and blower technology, which is applied in the field of tea frying machines, can solve the problems of low tea frying efficiency, decline in tea quality, poor tea heating uniformity, etc., and achieve the effect of improving aroma and quality, improving quality, and evenly heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

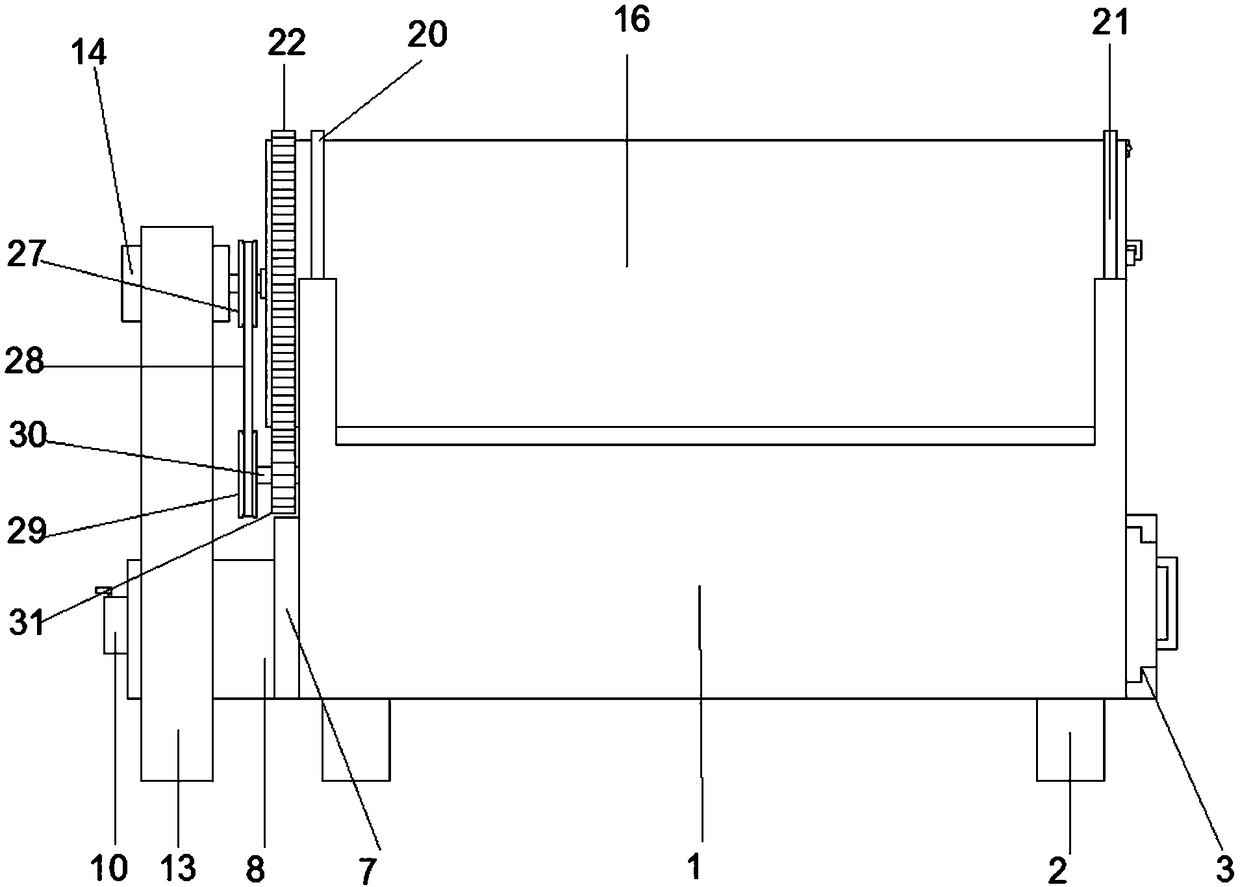

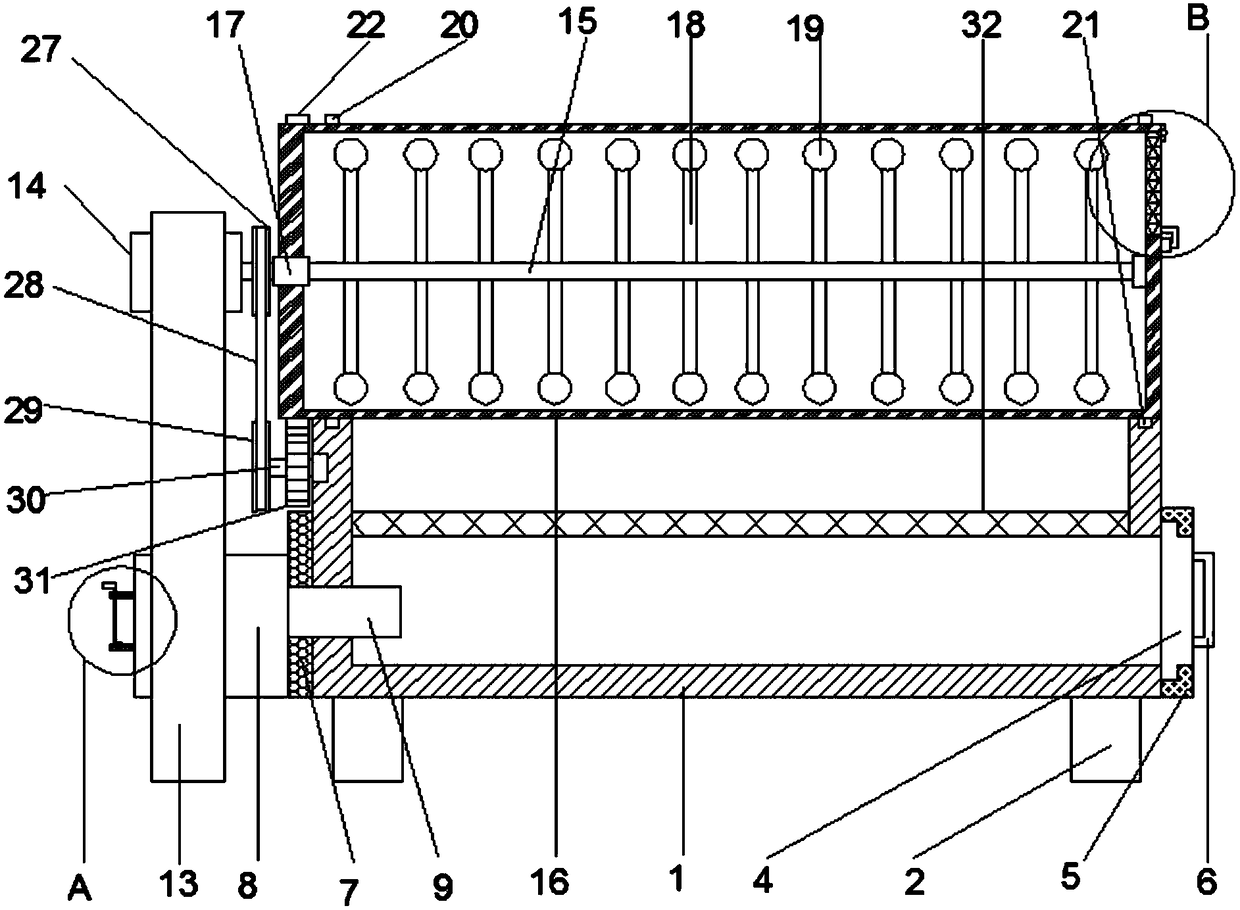

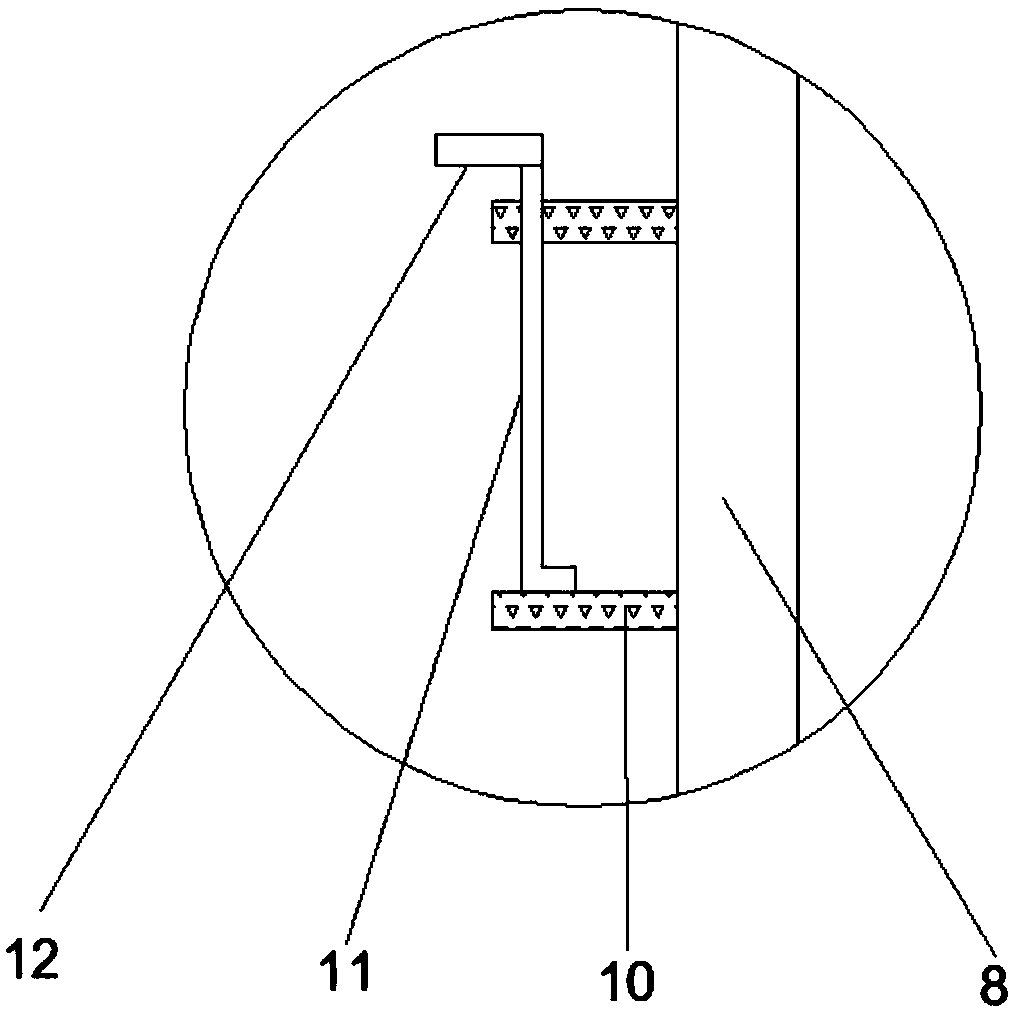

[0020] like Figure 1-Figure 4 As shown, a tea frying machine proposed by the present invention includes a coal furnace shell 1, a waste discharge door assembly 3, a blower 8, a motor 14, a tumble barrel 16 and a kneading ball 19, and the left and right sides of the lower end of the coal furnace shell 1 are provided There are support legs 2, a waste discharge door assembly 3 is provided at the lower end of the right side of the coal furnace shell 1, a coal rack 32 is provided at the inner middle of the coal furnace shell 1, and a heat insulation board 7 is provided at the lower left side of the coal furnace shell 1, and the heat insulation board 7 The blower 8 is arranged on the left side, and the middle part of the right side of the blower 8 is provided with a blowing pipe 9. The right end of the blowing pipe 9 runs through the heat shield 7 and communicates with the coal furnace shell 1. The left side of the blower 8 is provided with a suction pipe 10, and the left side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com