Multiple organic extraction device and method

An extraction device and multiple technologies, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve the problems of low purity of extracted products, waste of solvents, and poor temperature control, saving separation and inspection time and reducing raw materials. Waste, overcoming complex effects of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

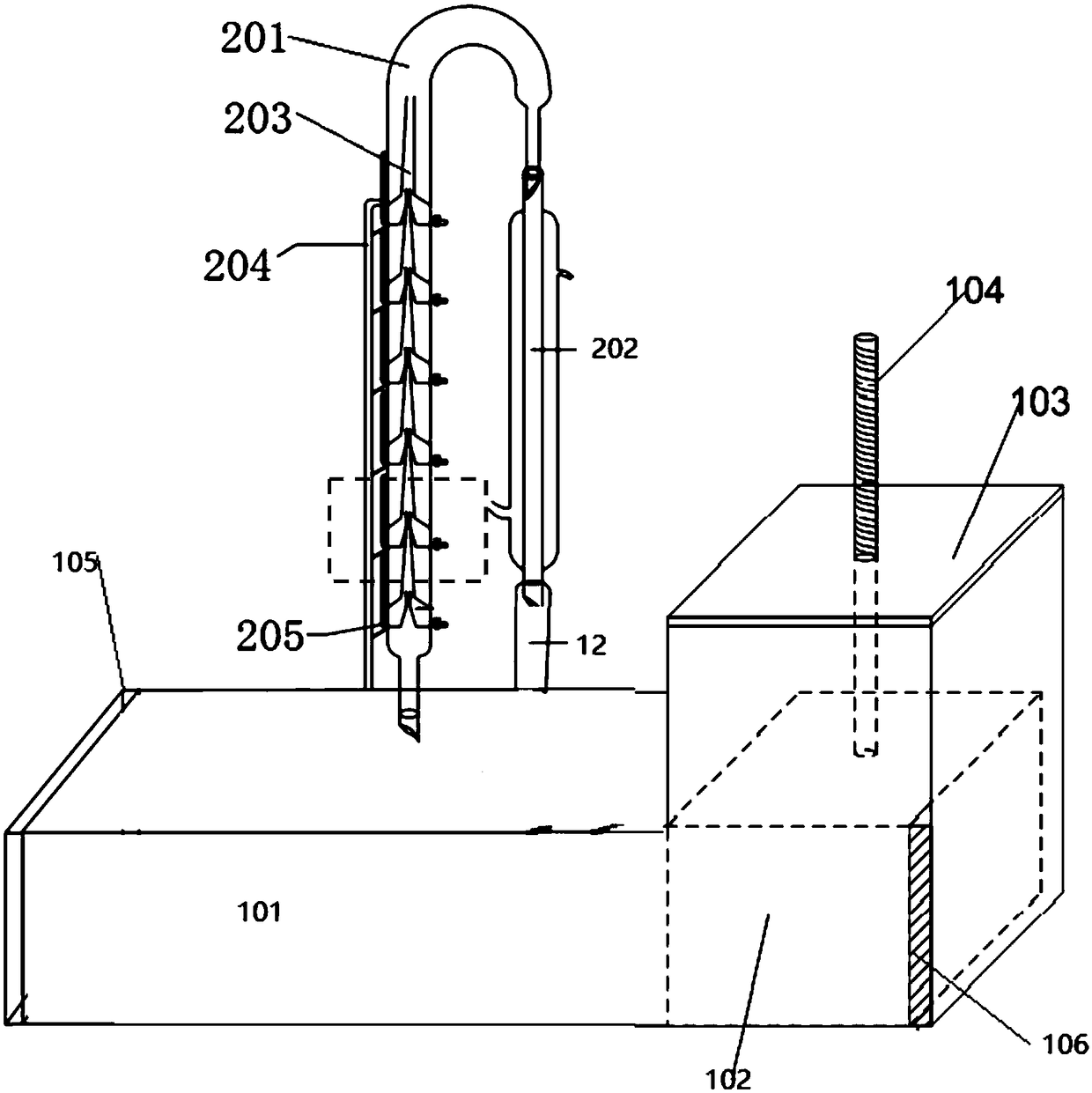

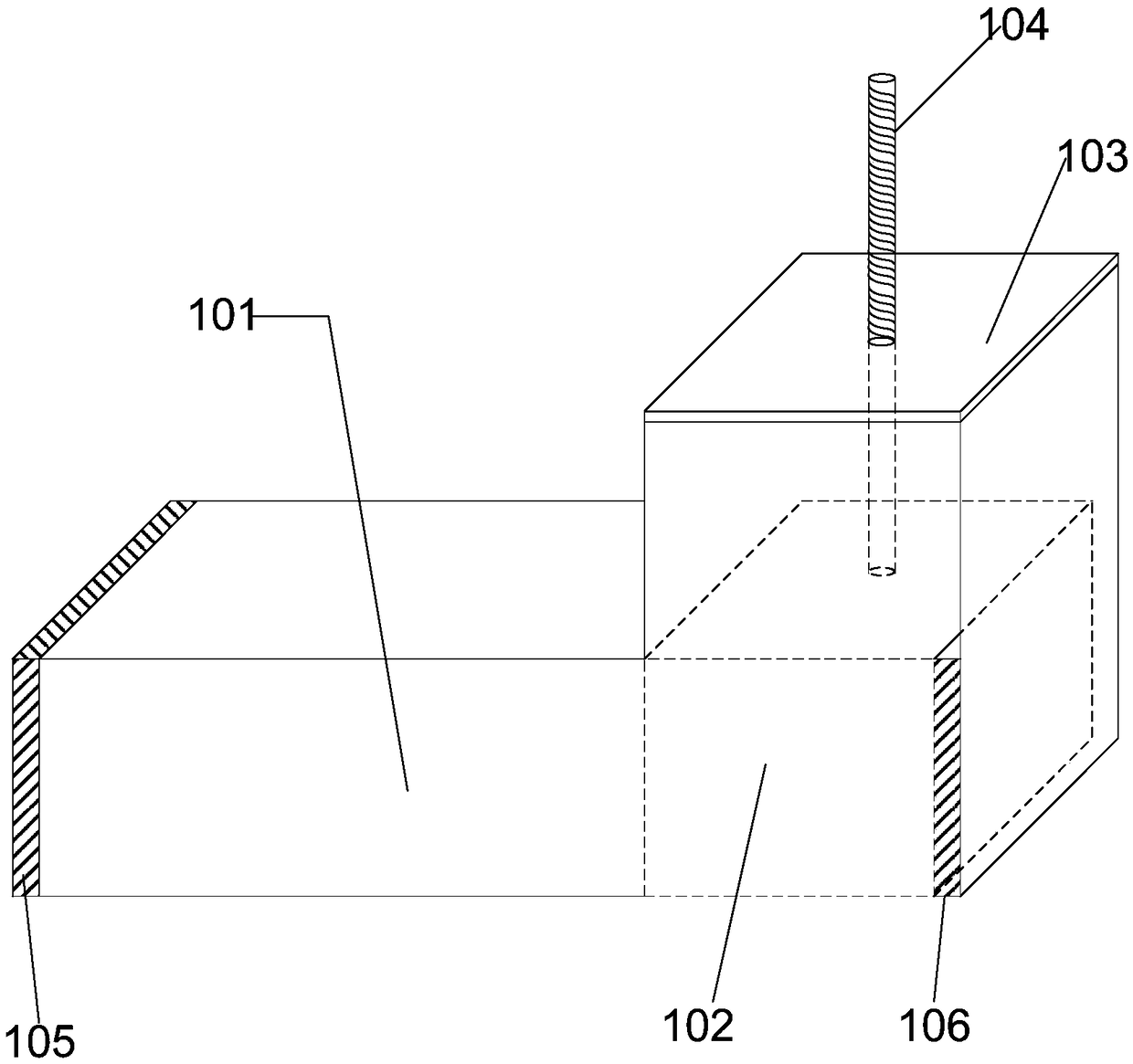

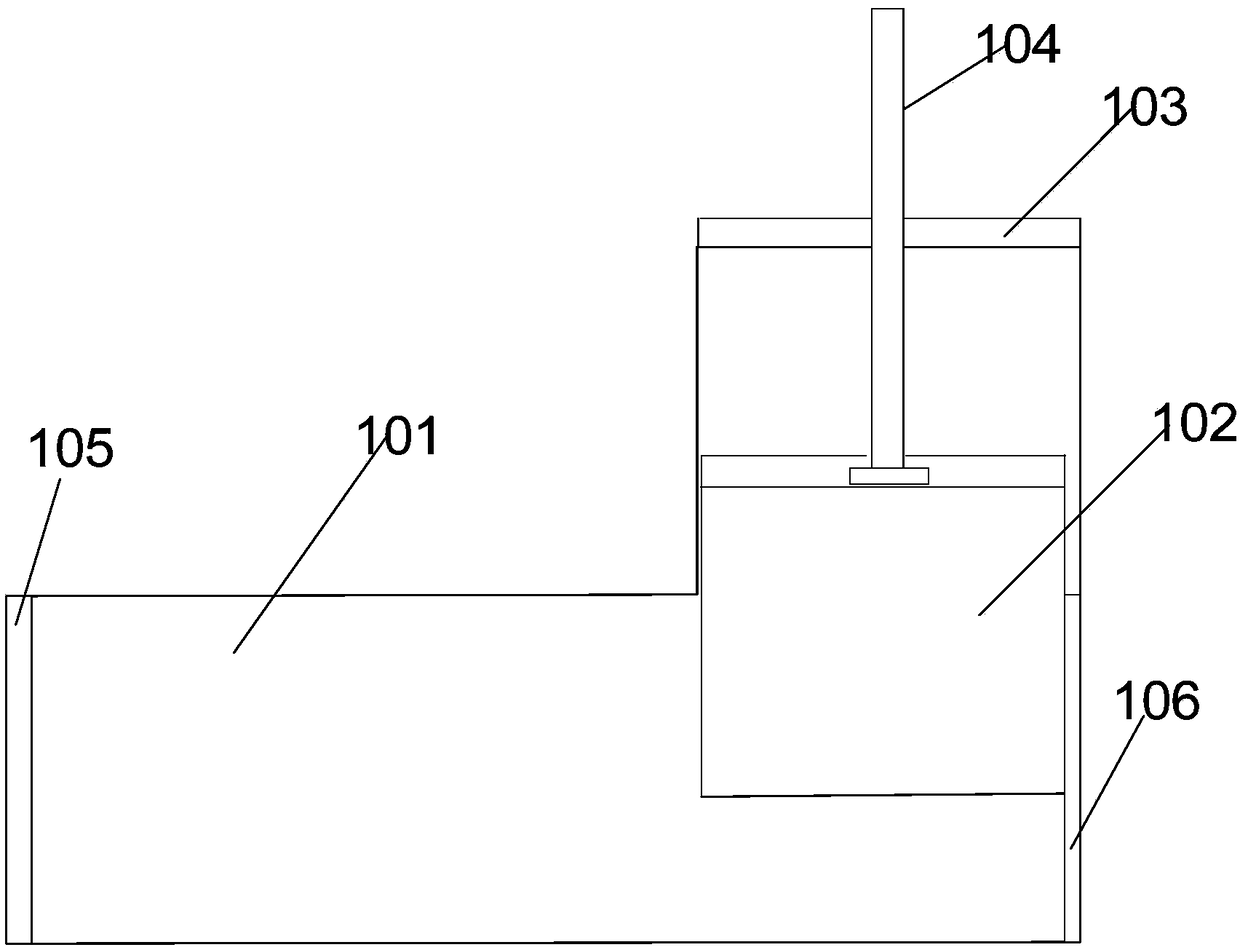

[0051] In this example, various organic substances in peppers were extracted. First dry 500g of chili and mash it. Open the top cover of the raw material pool, put the pretreated material in the raw material pool 102; place the raw material pool 102 loaded with materials in the dissolution pool, and the raw material pool is located in the lower cuboid processing pool. Inject solvent into ethanol through the solvent inlet on the back; start the ultrasonic wave source device through the controller, and ultrasonically oscillate and pulverize the material, while the material is completely soaked in the extraction solvent; repeatedly turn on the microwave wave source device intermittently through the controller to perform microwave frequency conversion extraction, so that The substance in the pepper is dissolved in the solvent passed through. Turn the screw 104 so that the raw material pool is completely located in the accommodation area. Next, the microwave wave source device is...

example 2

[0056] In this example, various organic substances in peppers were extracted. First dry 1000g of chili and mash it. Open the top cover of the raw material pool, place the pretreated material in the raw material pool 102; place the raw material pool 102 loaded with the material in the dissolution pool, and the raw material pool is located in the treatment pool of the cuboid structure of the bottom. Inject solvent into ethanol through the solvent inlet on the back; start the ultrasonic wave source device through the controller, and ultrasonically oscillate and pulverize the material, while the material is completely soaked in the extraction solvent; repeatedly turn on the microwave wave source device intermittently through the controller to perform microwave frequency conversion extraction, so that The substance in the pepper is dissolved in the solvent passed through. When the induction system of the microwave sensor detects that the solubility of capsanthin in ethanol in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com