Flexible welding and positioning device for sheet parts

A technology for welding positioning and parts, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of complex design structure, complex structure, single height, etc., and achieve high reuse rate, simple device structure, and increased flexibility. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

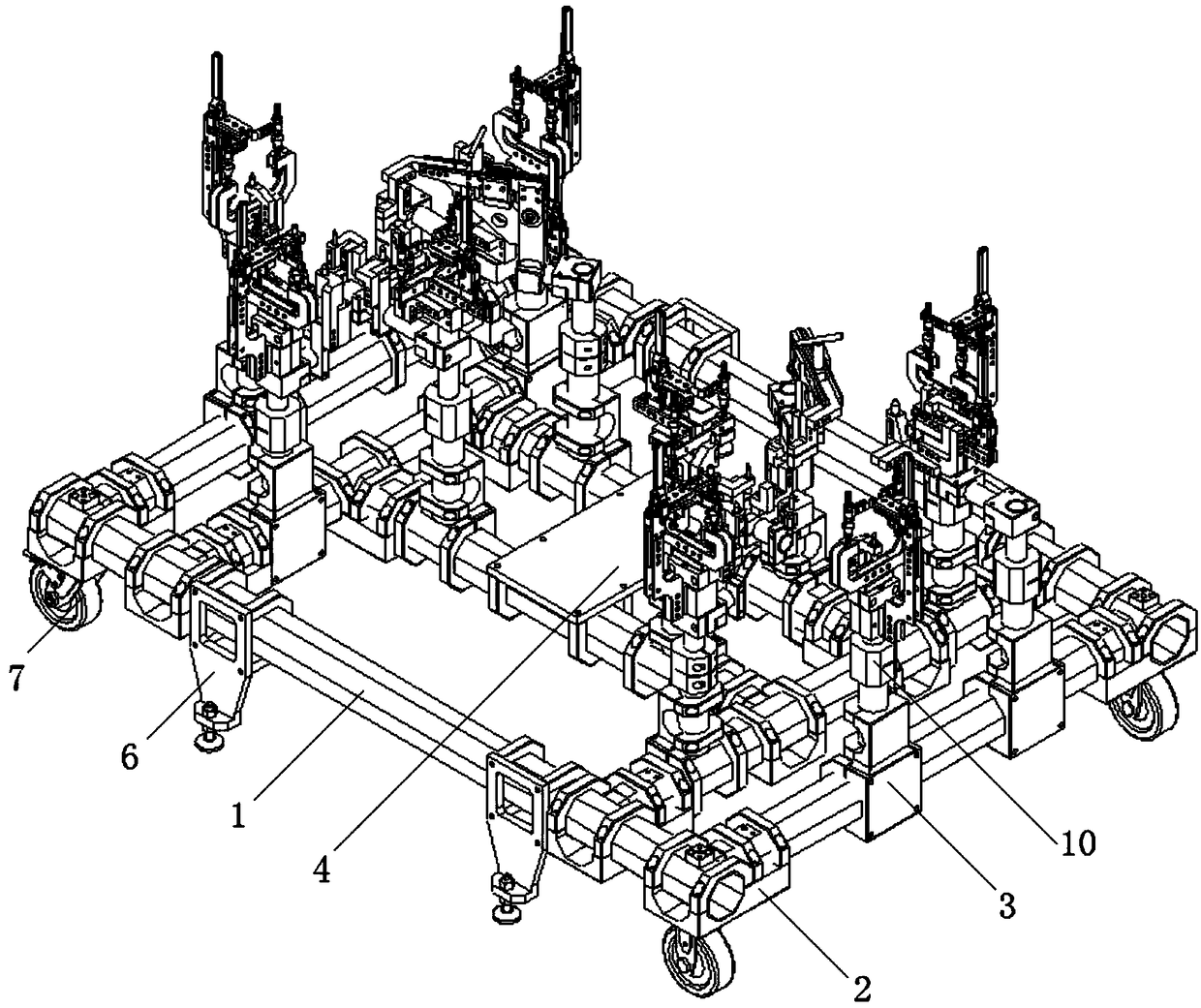

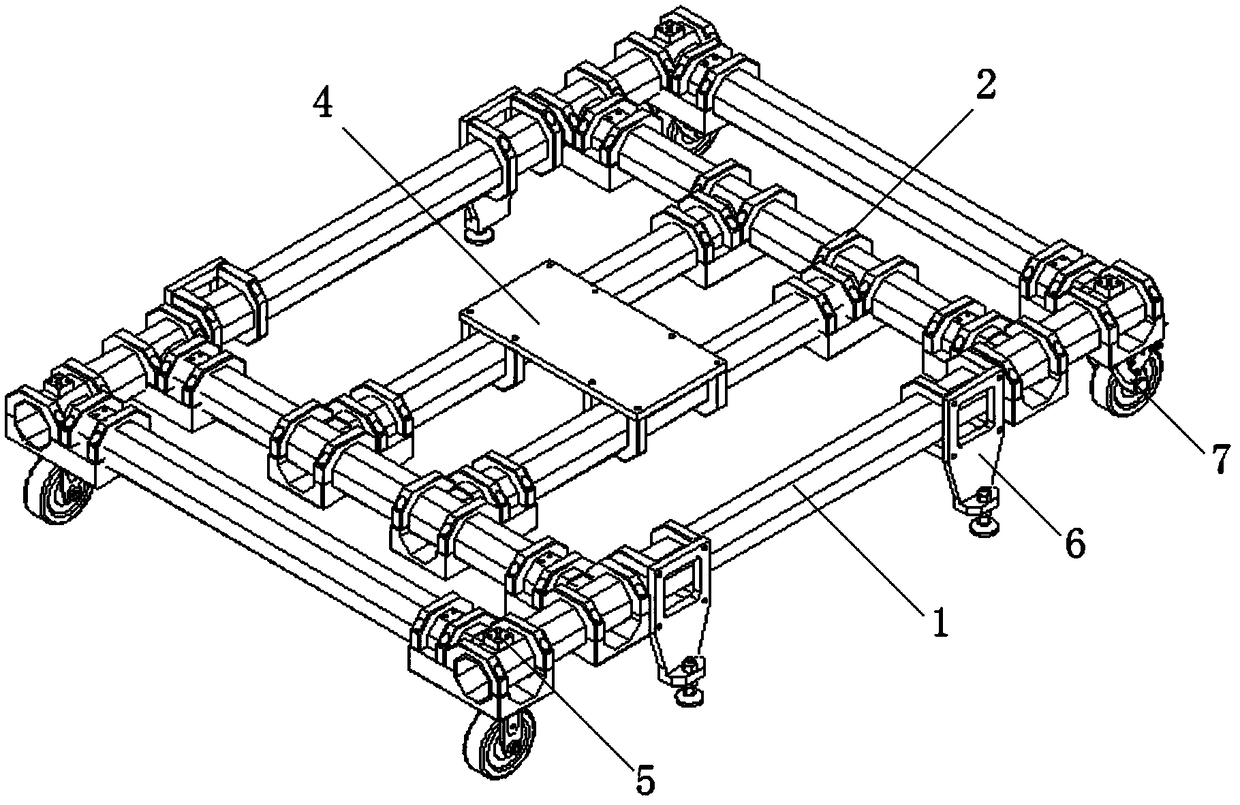

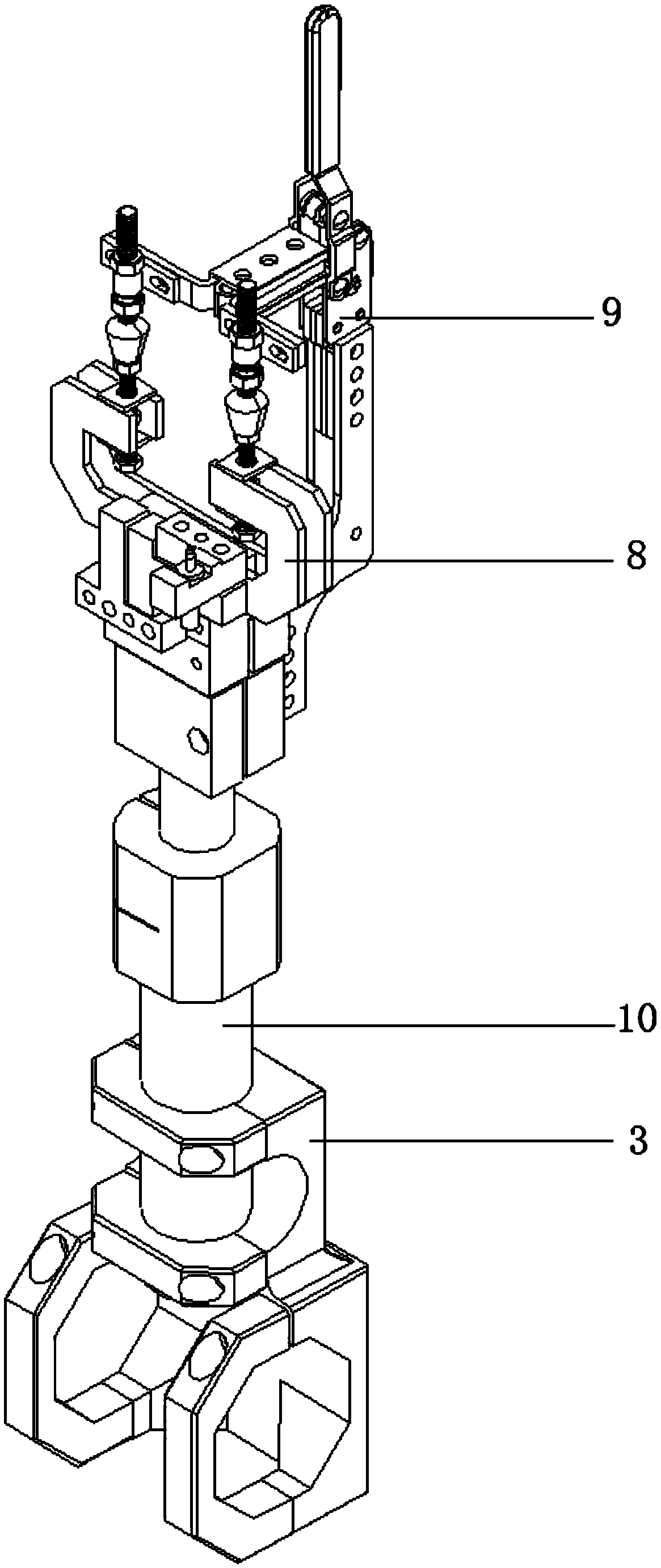

[0039] A flexible welding positioning device for thin plate parts, such as figure 1 As shown, the welding positioning tool for thin plate parts includes a flexible tooling base and a column mechanism on the flexible tooling base, such as figure 2, the flexible tooling base is a square frame structure composed of multiple long rod profiles 1 through profile buckles 2, the lower end of the column mechanism is fixed on the long rod profile 1 through the column buckles 3, and can be moved along the plane of the flexible tooling base The position of the long pole profile 1 can be adjusted arbitrarily. The flexible tooling base is arranged parallel to the long rod profiles 1 in the length direction or width direction, the long rod profiles 1 in the length direction and width direction are perpendicular to each other, and the profile buckles 2 are arranged at their joints and locked by positioning pins. In this embodiment The long rod profile 1 is an octagonal hollow tube. Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com