Fixture with high-sealing property for abrasive flowing polishing of inner surface of linear tube

An inner surface, abrasive flow technology, applied in the direction of grinding workpiece supports, can solve the problems of poor economy, waste of resources, low viscoelastic effect, etc., and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

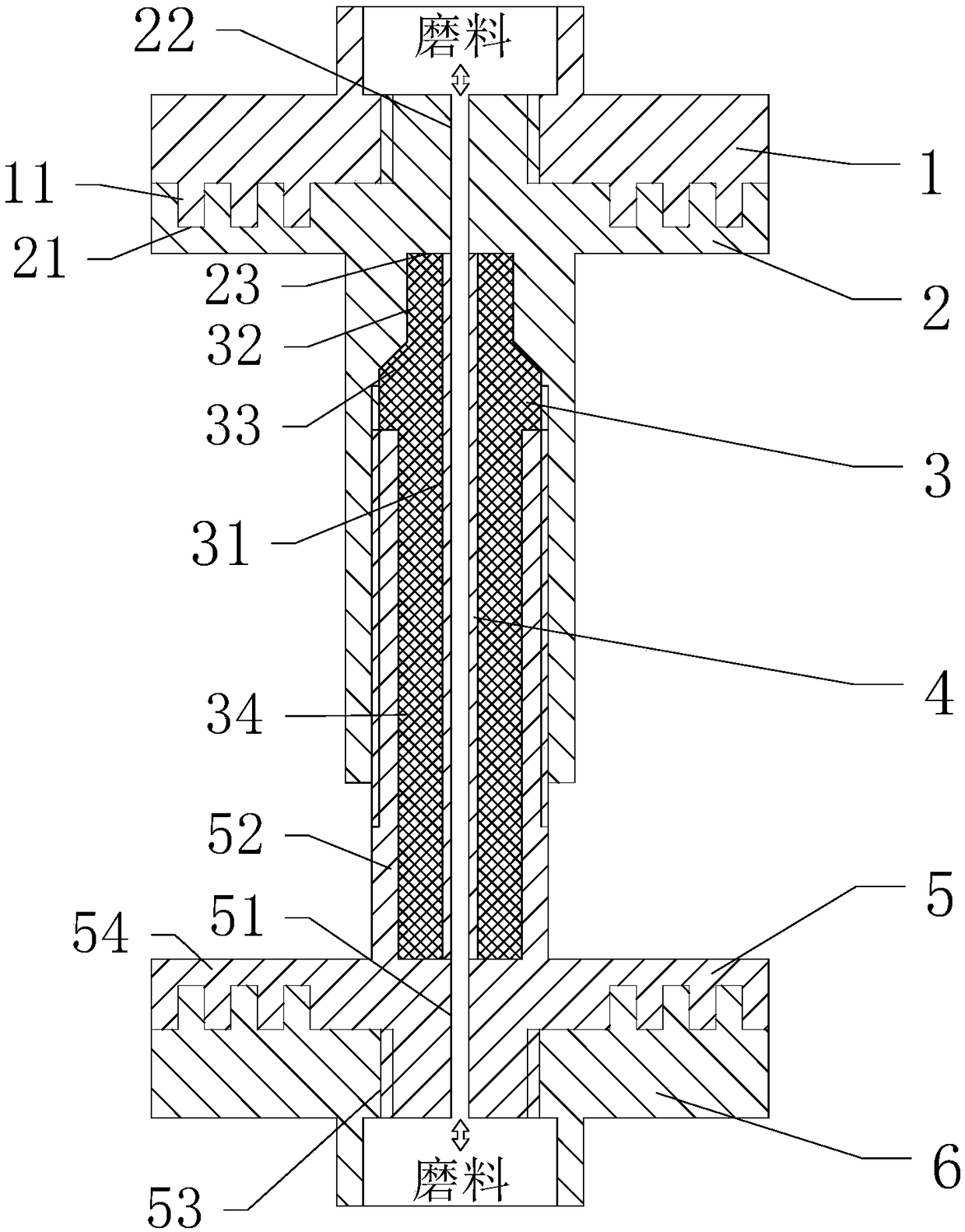

[0025] like figure 1 A high-tightness jig for abrasive flow polishing of the inner surface of a straight pipe is shown, including: a feeding cylinder 1 , an outer buckle jig 2 , a nylon bushing 3 , an inner buckle jig 5 and a lower material cylinder 6 .

[0026] The feeding cylinder 1 has a cylindrical body with a certain inner diameter and length, the top is provided with an abrasive chamber A for containing abrasives, and the bottom of the feeding cylinder 1 has an internal thread at the center;

[0027] The upper part of the outer buckle fixture 2 is provided with an external thread, which is connected with the internal thread at the bottom of the feeding cylinder 1. Its height is the same as the length of the internal thread of the feeding cylinder 1. The end surface is fitted with a rotary seal on the lower surface of the feeding cylinder 1. The deep groove 21, the lower surface of the feeding cylinder 1 is provided with the end face rotating tooth 11 that cooperates with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap