Sand blasting cleaning equipment for inner wall and outer wall of steel pipe and cleaning method

A technology for blast cleaning, inner and outer walls, applied in metal processing equipment, used abrasive treatment devices, abrasives, etc. The effect of air pollution, improving production efficiency and fast cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

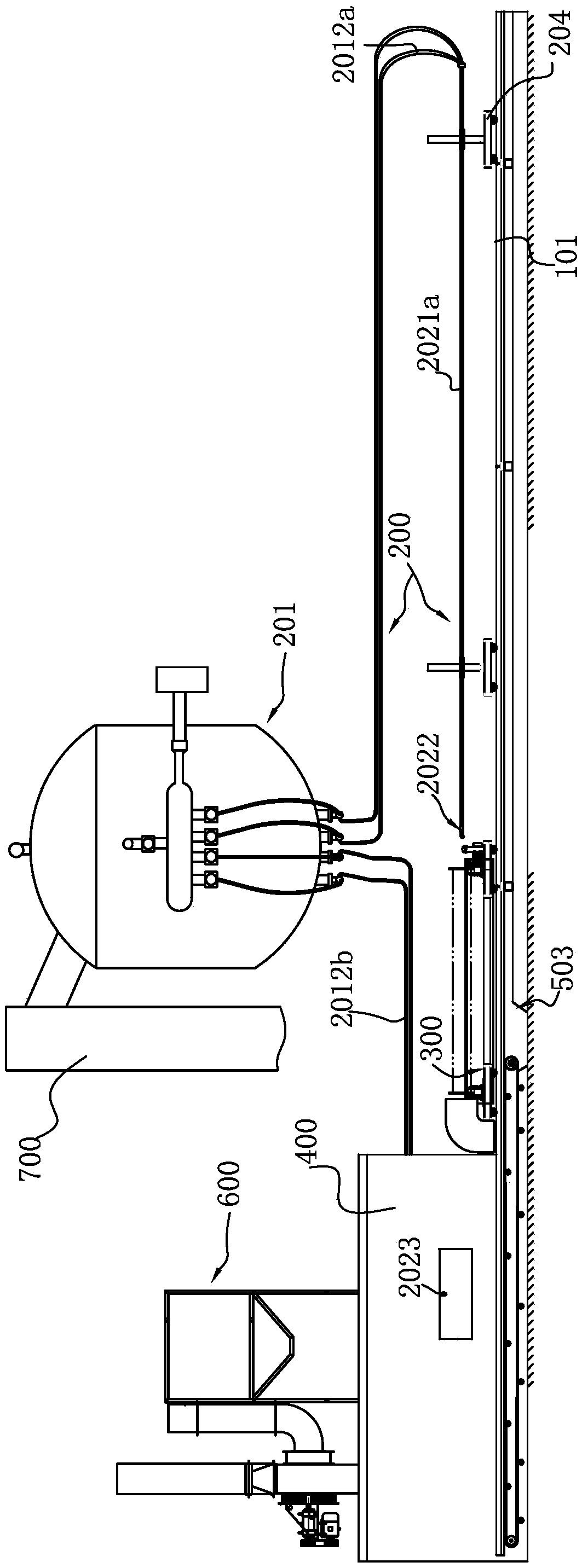

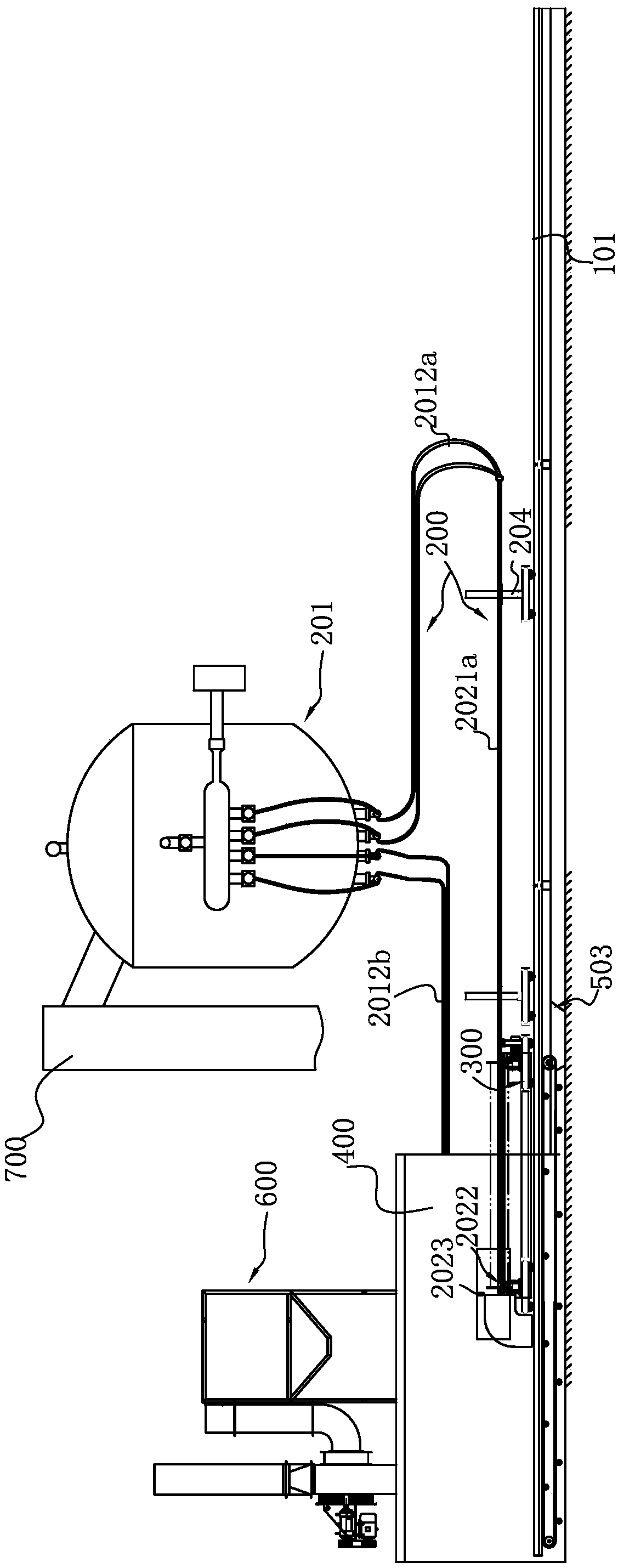

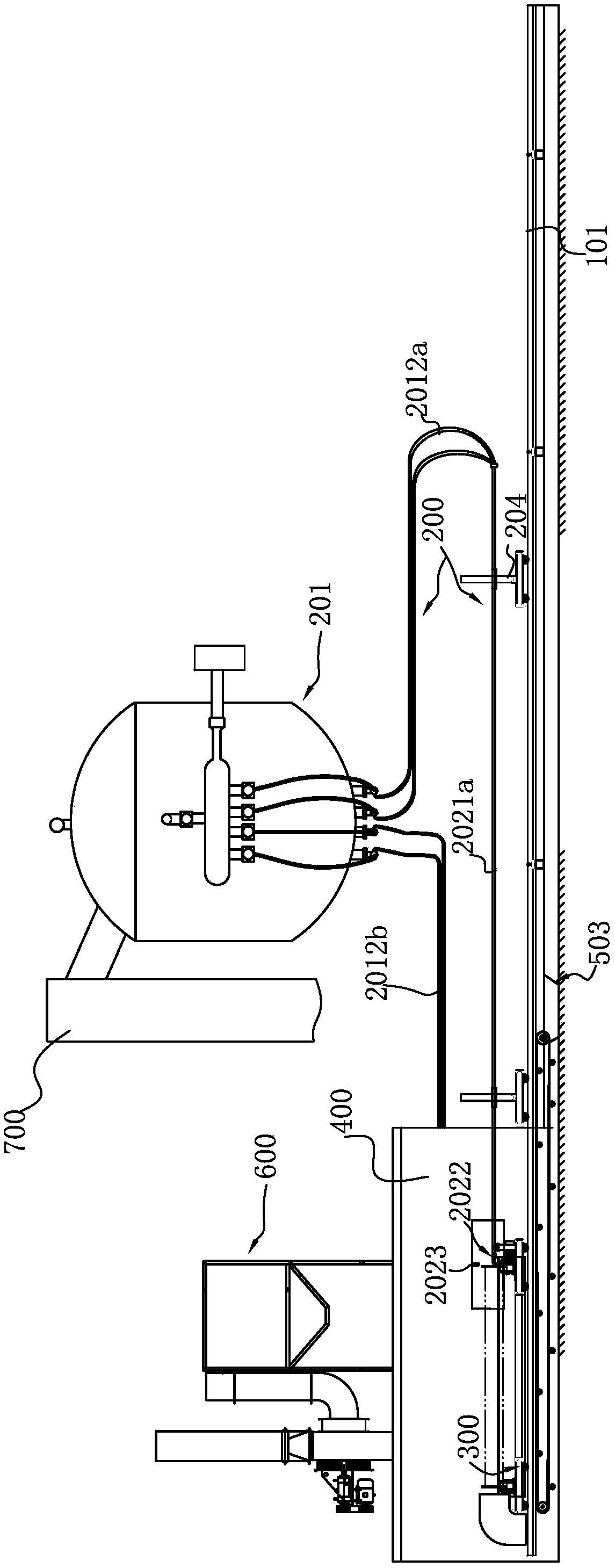

[0048] Such as Figure 1 to Figure 6 In the sand blasting cleaning equipment for inner and outer walls of steel pipes shown together, the guide rail 101 extends into the cleaning chamber 400 from one end;

[0049] The material loading system 300 includes a material loading vehicle 301 driven by the first walking power device (not shown in the figure) and a steel pipe rotating device 302 arranged on the material loading vehicle 301. The material loading vehicle 301 is arranged on the guide rail 101, and the steel pipe rotates The rotation axis of the steel pipe H supported by the device 302 is set parallel to the guide rail 101;

[0050] The sand blasting system 200 includes a sand outlet tank 201 controlled by compressed air, a sand delivery pipe 2012, a spray pipe 2021, a nozzle device 202 and a steel grit collection device. The steel grit collection device recycles the steel grit ejected from the nozzle device 202 to the sand outlet tank 201;

[0051] The nozzle device 202...

Embodiment 2

[0071] The only difference between this embodiment and Embodiment 1 is that, as Figure 7 and Figure 8As shown together, the inner wall nozzle device 2022 includes a nozzle body 2022a and a nozzle connector 2023a connected together. The nozzle body 2022a is provided with a straight-through spray hole, and the spray hole includes two tapered holes opposite to each other. Throat holes 20220 are arranged between the tapered holes, and the axes of the two tapered holes and the throat holes 20220 are on the same straight line. A cage 2024 is arranged between the head 2023a and the nozzle 2021a on the inner wall, and the cage 2024 bends the hose 2025 so that the nozzle body 2022a maintains a fixed spraying angle, which avoids gaps in the spray hole of the nozzle body 2022a during sandblasting, which affects the steel grit. The range of spraying will affect the cleaning effect of the inner and outer walls of the steel pipe.

[0072] The cleaning equipment in this embodiment is mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com