A fully automatic rubbing production system and its production method

A fully automatic, electric push rod technology, applied in stamping, printing, etc., can solve the problems of inconvenient tool management and use, lack of coherence in the overall operation, and inability to make finished products well, so as to achieve convenient and efficient management and use , The overall operation is smooth and coherent, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

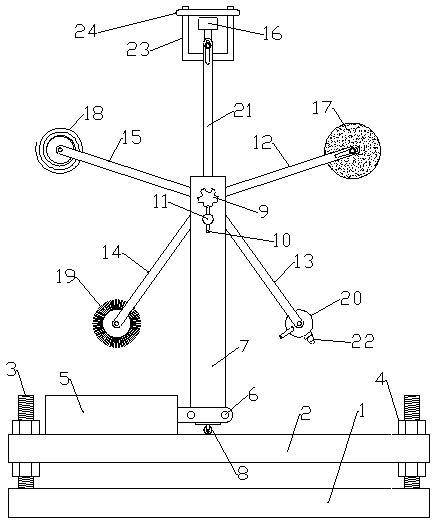

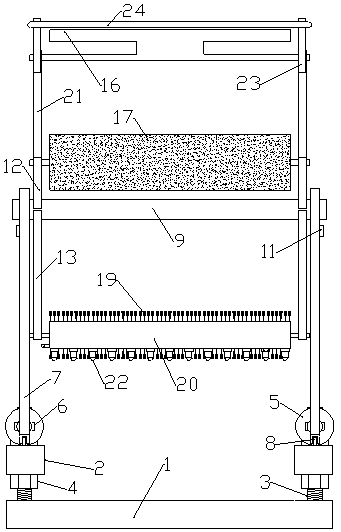

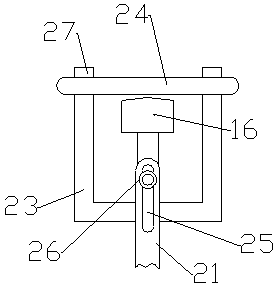

[0023] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, a fully automatic rubbing making system includes a base 1, on which two supporting rails 2 that can move longitudinally are arranged in parallel, and on the two supporting rails 2 There is a fully automatic rubbing device. Described full-automatic rubbing device comprises the electric push rod 5 that is horizontally fixedly installed on each support track 2, and the output end of each electric push rod 5 is all vertically fixedly installed with upright bar 7, and the upper part of two upright bar 7 is laterally Connected to the supporting rotating shaft 9, the first supporting rod 12, the second supporting rod 13, the third supporting rod 14, the fourth supporting rod 15 and the fifth supporting rod are equally arranged on the circumferential direction of the supporting rotating shaft 9. Rod 21, the first support rod 12 is provided with an ink bag 17, the second support rod 13 is provided with a water outlet pipe 20 with a hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com