Pure electric vehicle and powertrain system

A technology for powertrains and automobiles, applied in the direction of electric power units, power units, vehicle components, etc., can solve the problems of poor use effect, increased motor volume, increased cost, etc., to simplify assembly and positioning relationships, and avoid reliability Low, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

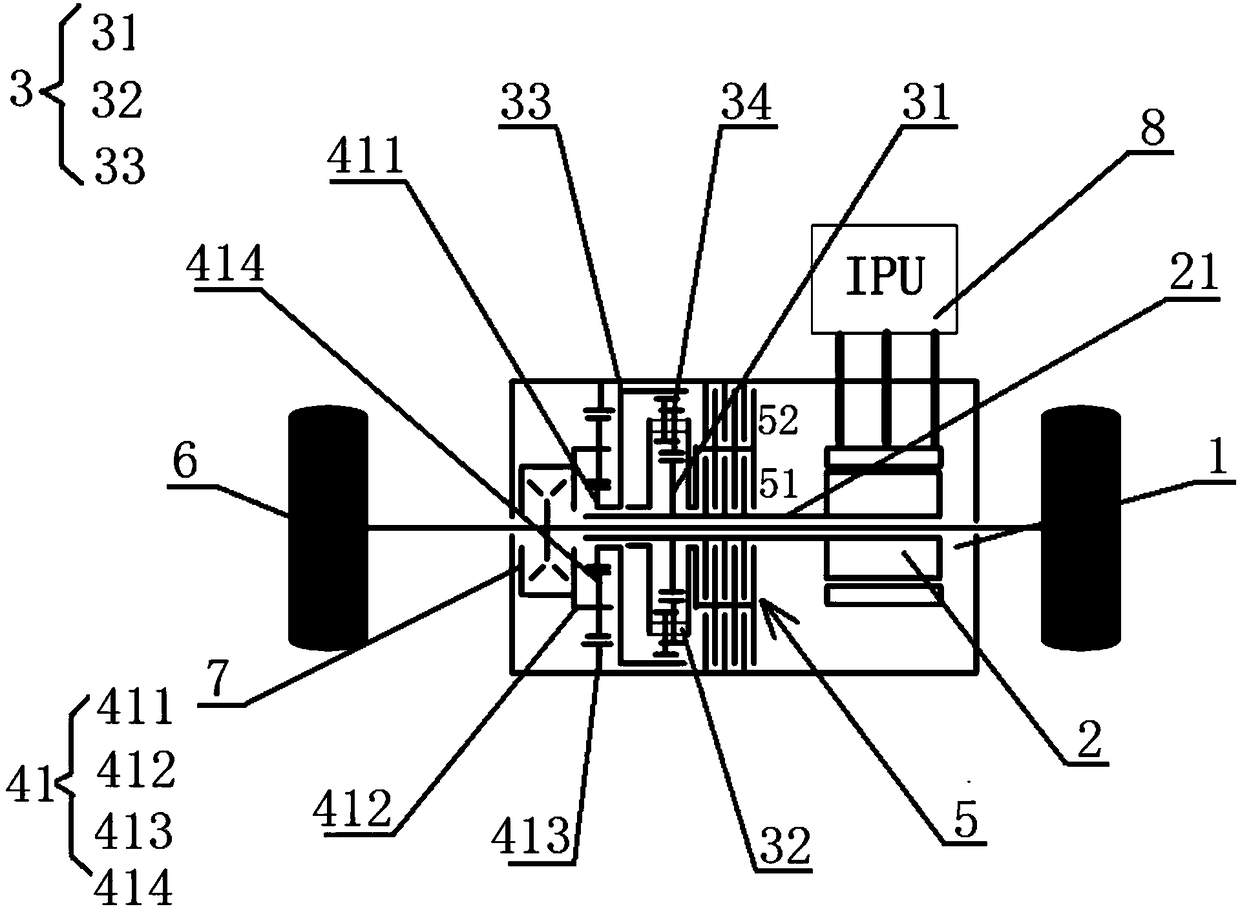

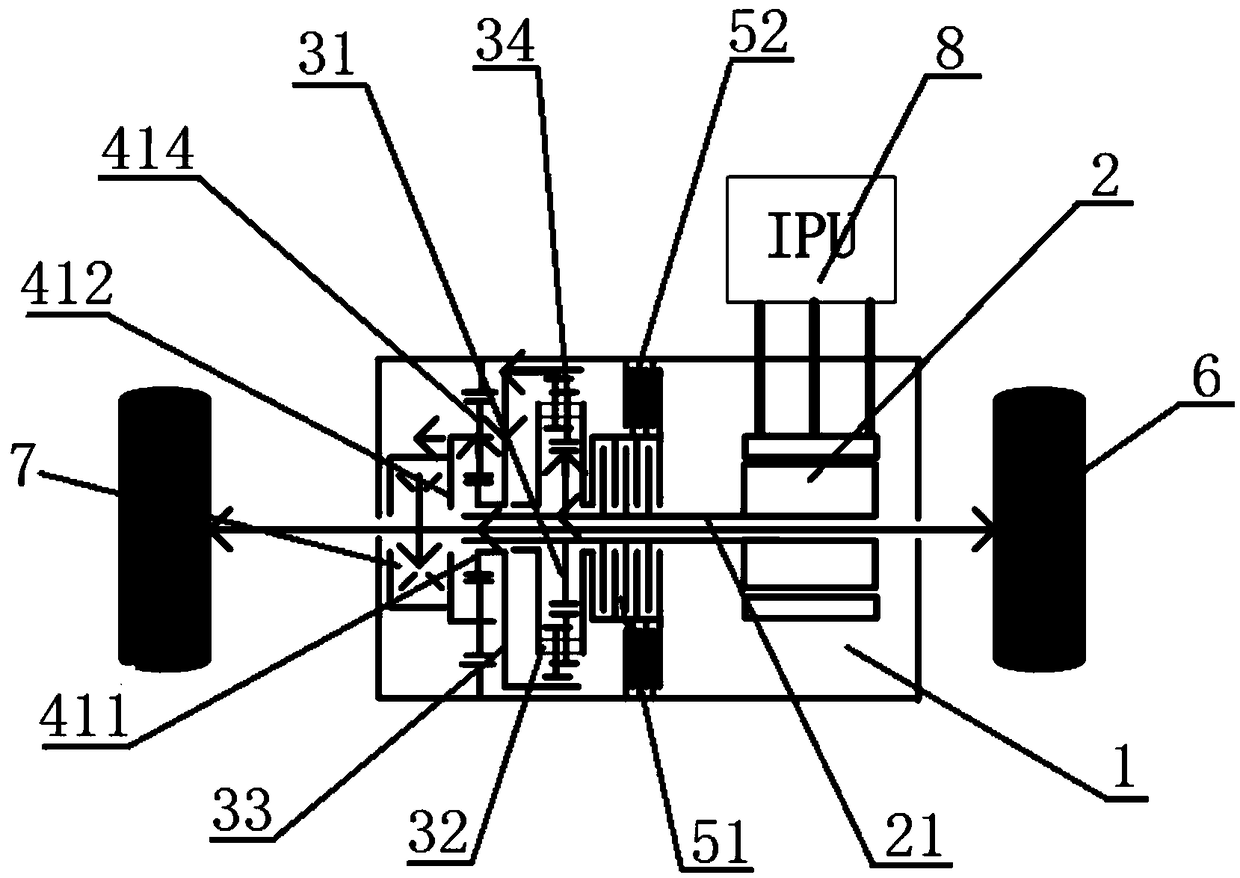

[0031] See Figure 1 to Figure 3 , The powertrain system of this preferred embodiment includes a housing 1, an electric motor 2, a first planetary row 3, a speed change mechanism 4 and a control shift device 5; the control shift device 5 is connected to the output shaft 21 of the motor and controls The shifting device 5 is connected to the housing 1, and the first planetary row 3 is connected between the control shifting device 5 and the speed change mechanism 4; the first planetary row 3 includes three first rotating elements, and the three first rotating elements are respectively The first sun gear 31, the first planet carrier 32, and the first ring gear 33; one of the three first rotating elements is connected to the housing 1, through the control shift device 5 The output shaft 21 of the electric motor is connected, and the control shift device 5 selectively works to realize the braking or rotation of the first rotating element connected with the output shaft 21 of the elec...

Embodiment 2

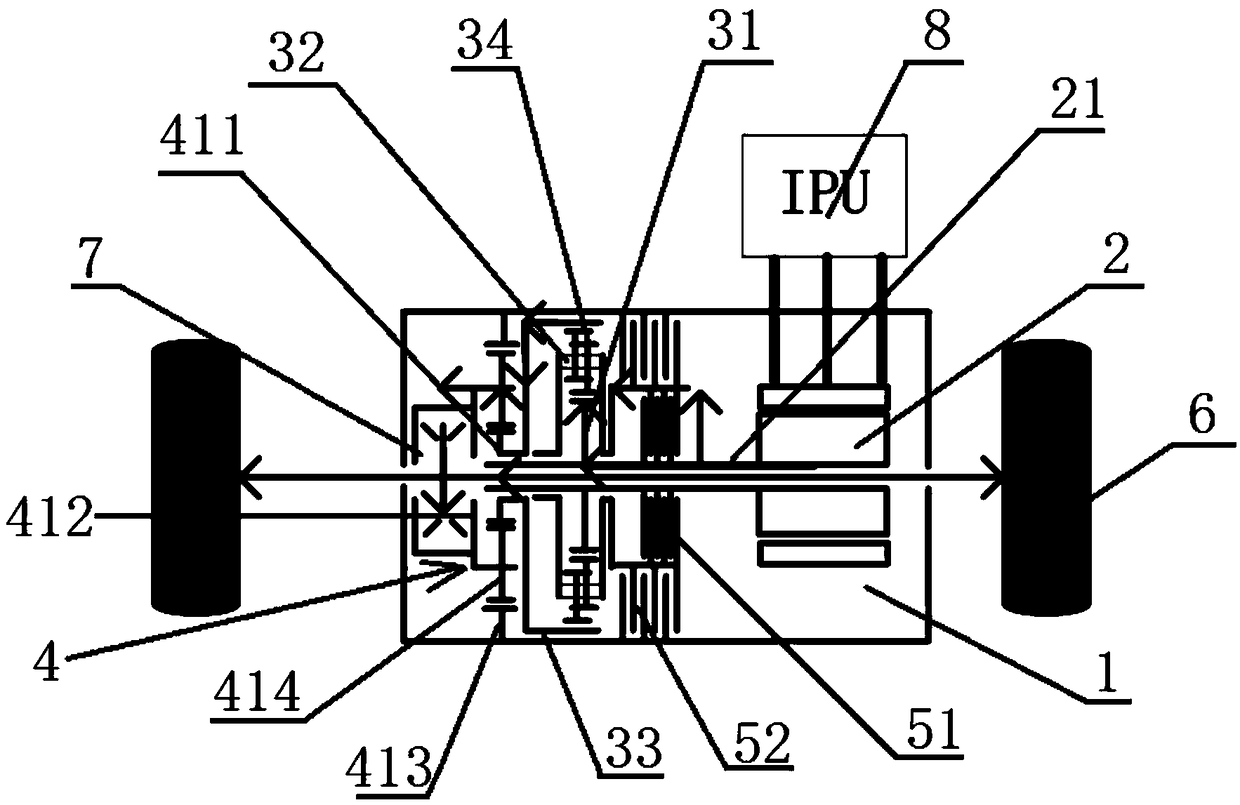

[0039] See Figure 4 The structural layout of the powertrain system in this preferred embodiment is substantially the same as that in the first embodiment, except that the speed change mechanism 4 includes a first gear device 42, a rotating shaft 43, and a second gear device 44. The first gear The device 42 is connected to the second gear device 44 through the shaft 43, the first gear device 42 is connected to the first ring gear 33, and the second gear device 44 is connected to the wheel end 6 of the automobile. The first gear device 42 includes a first gear device. The driving gear and the first driven gear. The second gear device 44 includes a second driving gear and a second driven gear. The power of the first planetary row 3 is transmitted through the first ring gear 33. A driving gear is connected to drive the first driving gear to rotate. The first driving gear and the first driven gear are meshed with each other. Power is transmitted from the first driven gear. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com