Transfer device

A technology for transferring equipment and equipment, applied in mechanical equipment, trolleys, transportation and packaging, etc., can solve the problems of easy discomfort, unable to provide facial cooling for workers, and hot working environment, and achieve the effect of avoiding physical discomfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

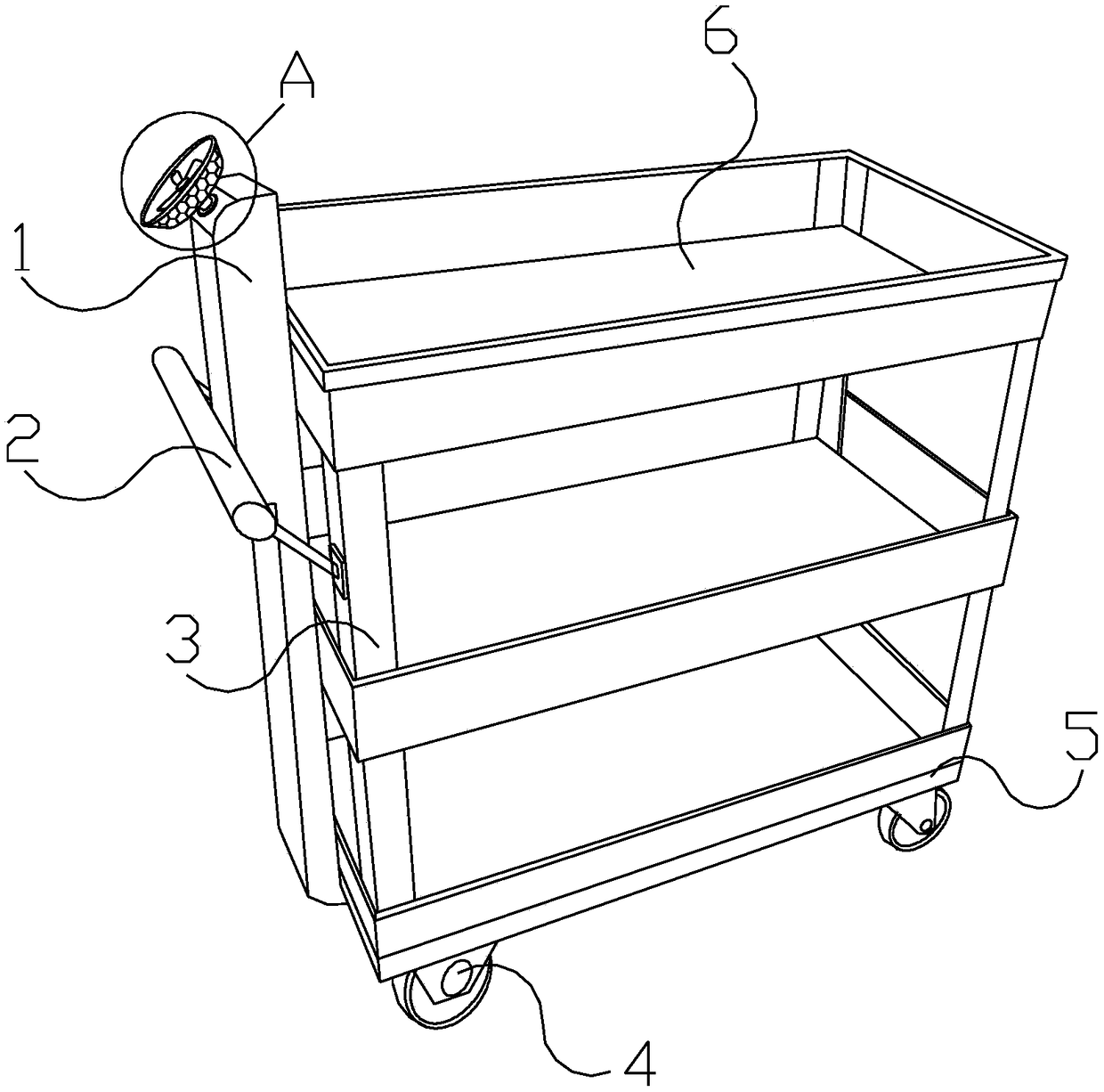

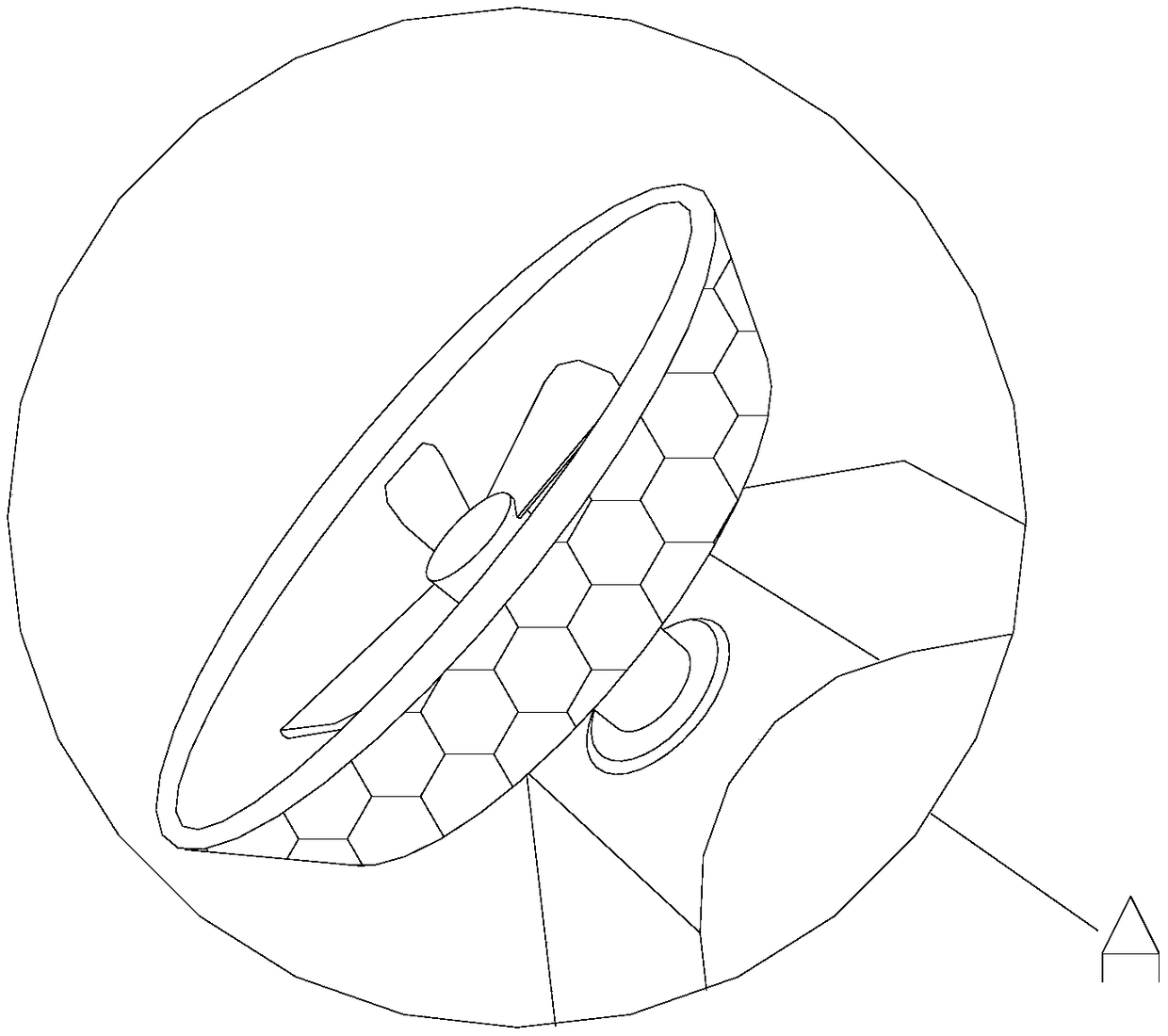

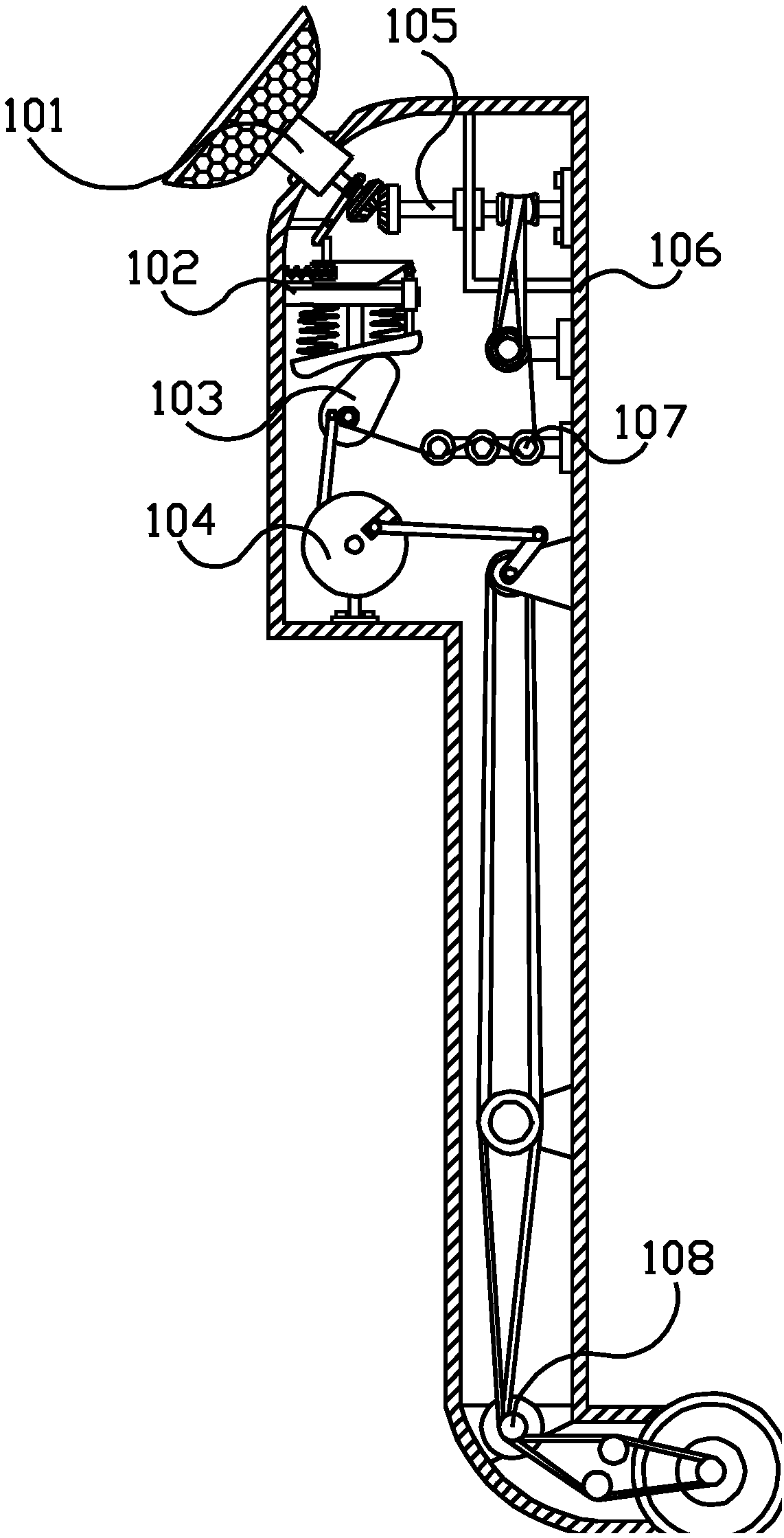

[0024] see Figure 1-Figure 6, the present invention provides a transfer device, the structure of which includes a cooling device 1, a device handle 2, a fixed bracket 3, a moving wheel 4, a device base 5, and a storage box 6. Installed on the four corners of the bottom of the equipment base 5, the upper end of the equipment base 5 is provided with a fixed bracket 3, and the upper left end of the fixed bracket 3 is provided with an equipment handle 2, and the cooling device 1 is installed on the fixed bracket by buckling At the left end of the bracket 3, there are three placement boxes 6 in total, which are evenly and equidistantly arranged inside the fixed bracket 3 by means of fitting. The cooling device 1 includes a blowing mechanism 101, a reset mechanism 102, a linkage mechanism 103, and a swing device. 104. The main transmission mechanism 105, the housing 106, the second transmission mechanism 107, and the third transmission mechanism 108. The inner lower end of the hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com