Packaging machine

A technology of packaging machine and air extraction mechanism, which is applied in the directions of packaging, transportation packaging, transportation and packaging, etc., which can solve the problems of increased labor intensity, burns, and high risk factor of workers' working environment, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

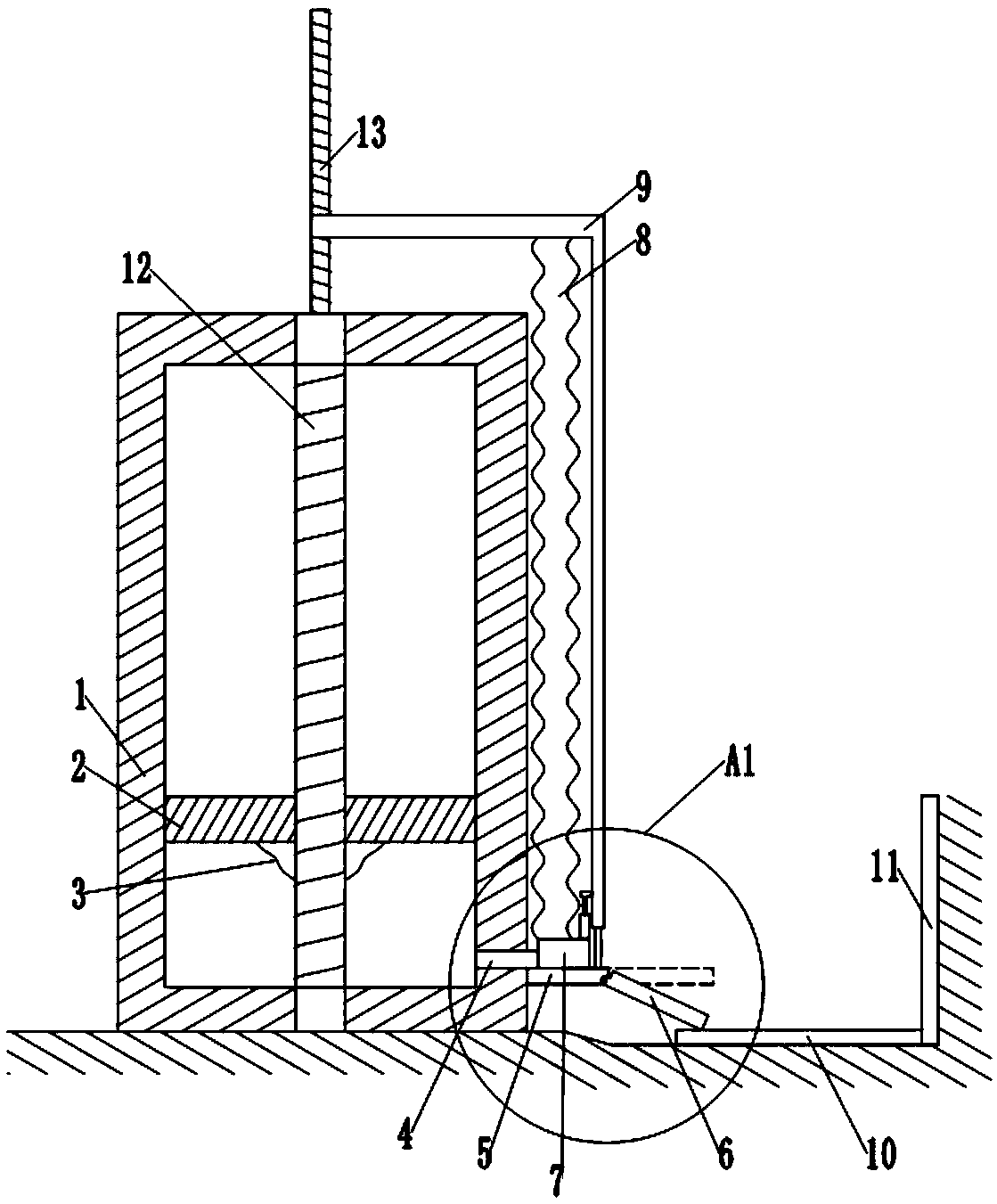

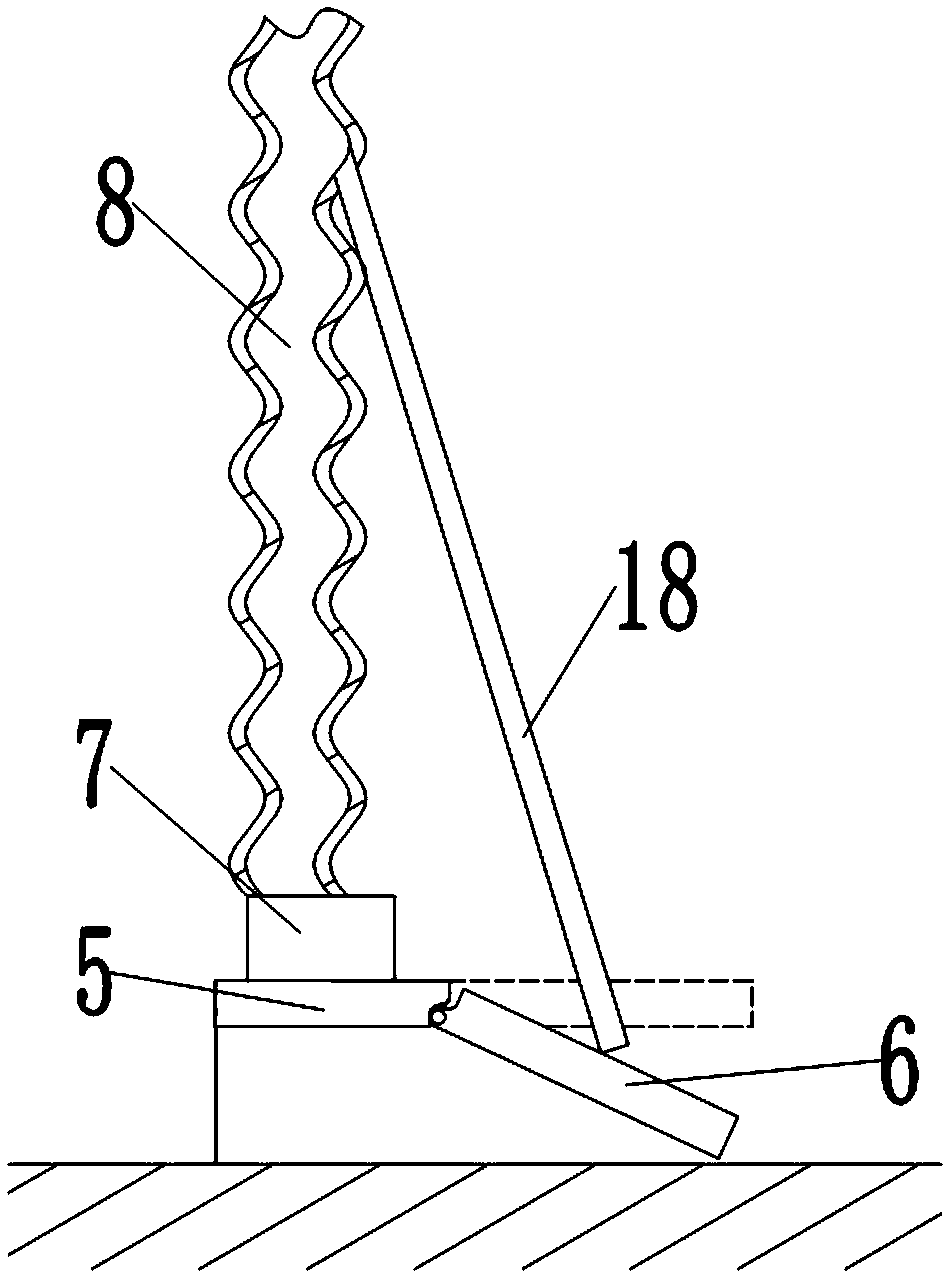

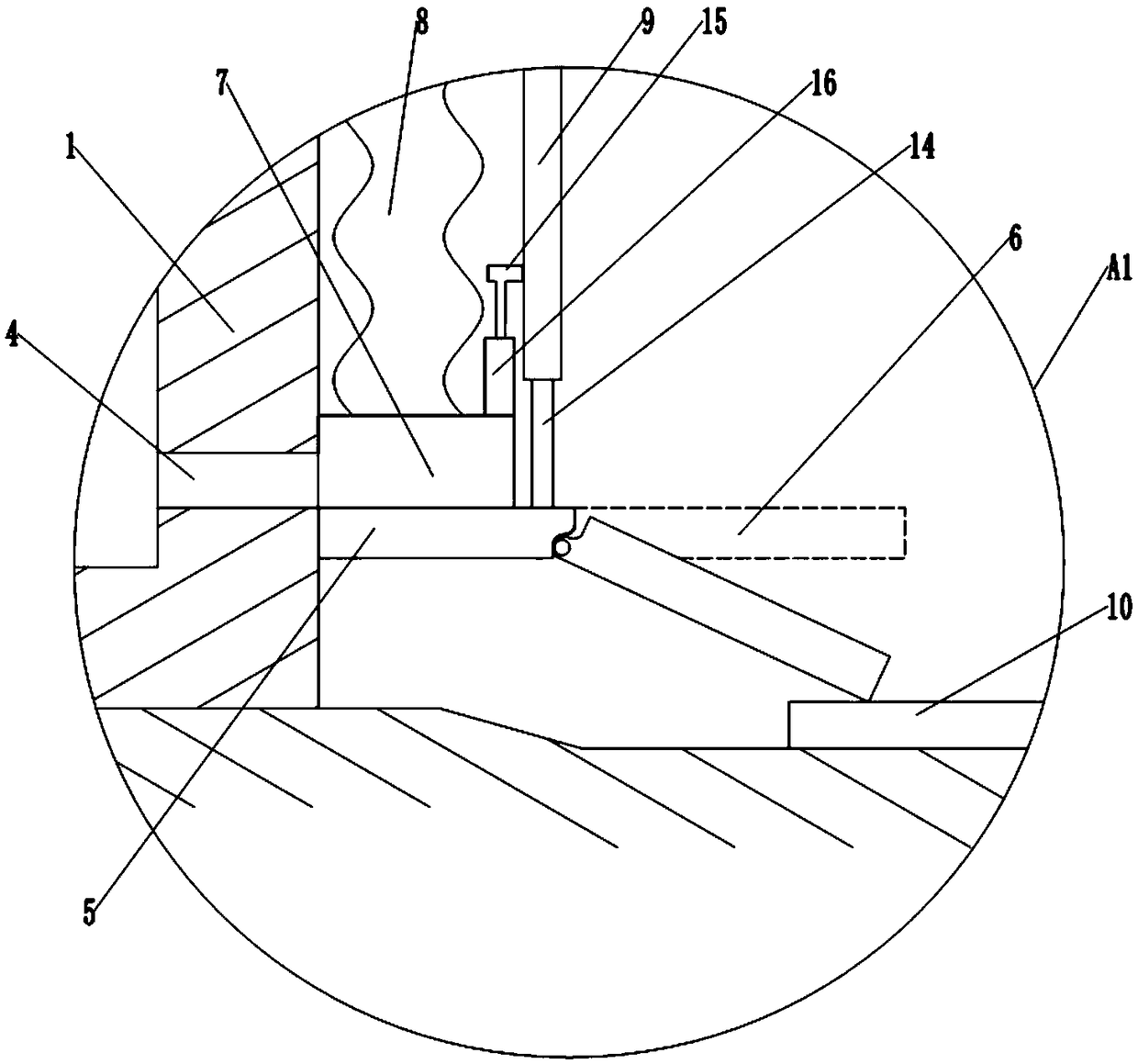

[0027] The reference signs in the drawings of the description include: cylinder 1, piston 2, retractable sealing membrane 3, vent hole 4, support platform 5, conversion plate 6, clamping block 7, elastic telescopic rod 8, connecting rod 9, conveyor belt 10 , baffle plate 11, lower leading screw 12, upper leading screw 13, heating block 14, card key 15, buckle lock 16, jaw 17, brake lever 18, through hole 41.

[0028] The embodiment is basically as attached figure 1 Shown:

[0029] A packaging machine includes a support, a clamping mechanism, an air suction mechanism and a packaging mechanism.

[0030] The air extraction mechanism includes a cylinder 1 and a lead screw connected in rotation with the cylinder 1. The bottom of the cylinder 1 is fixedly connected to the support, and the lead screw is connected with the output shaft of the motor. The lead screw is divided into an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com