Bottle cap and bottle plug capable of realizing automatic pressure relief

An automatic release and bottle cap technology, applied to bottle/container caps, capping, bottle filling, etc., can solve the problems of poor time control, safety hazards, time-consuming and labor-intensive problems, and achieve long-term use and good pressure relief effect , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

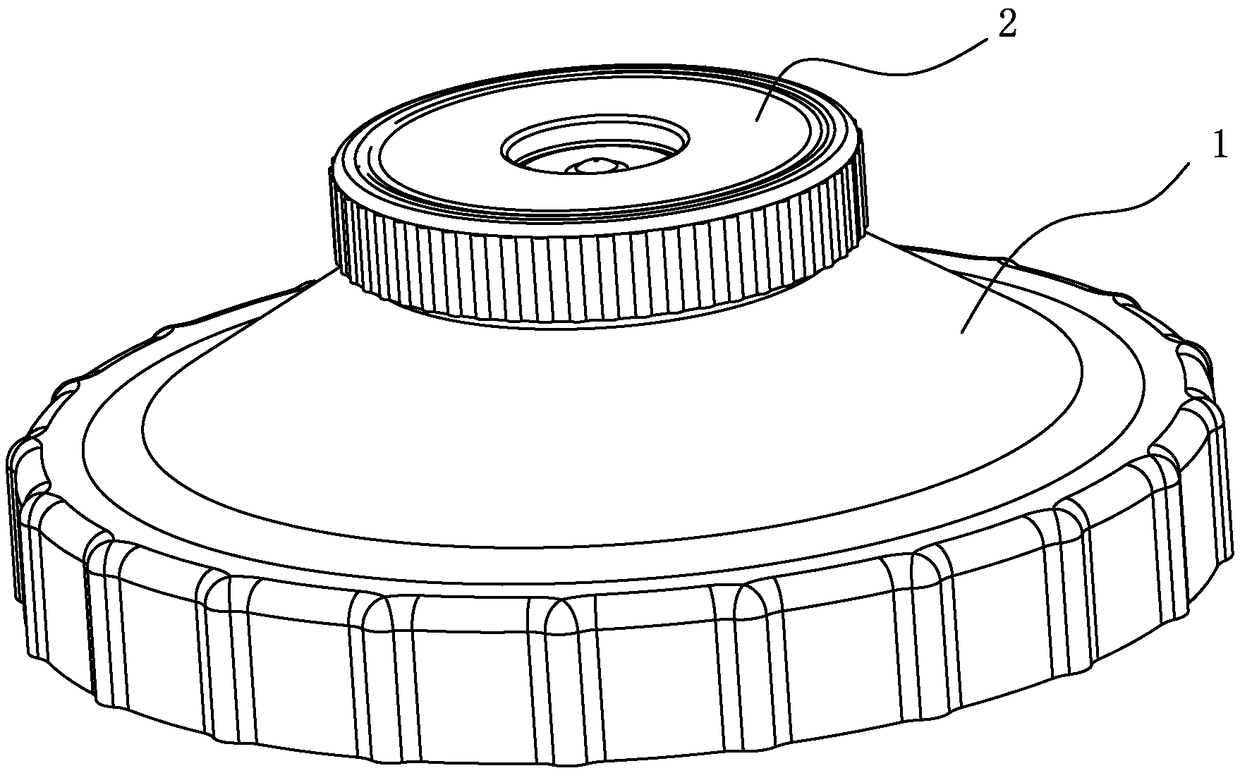

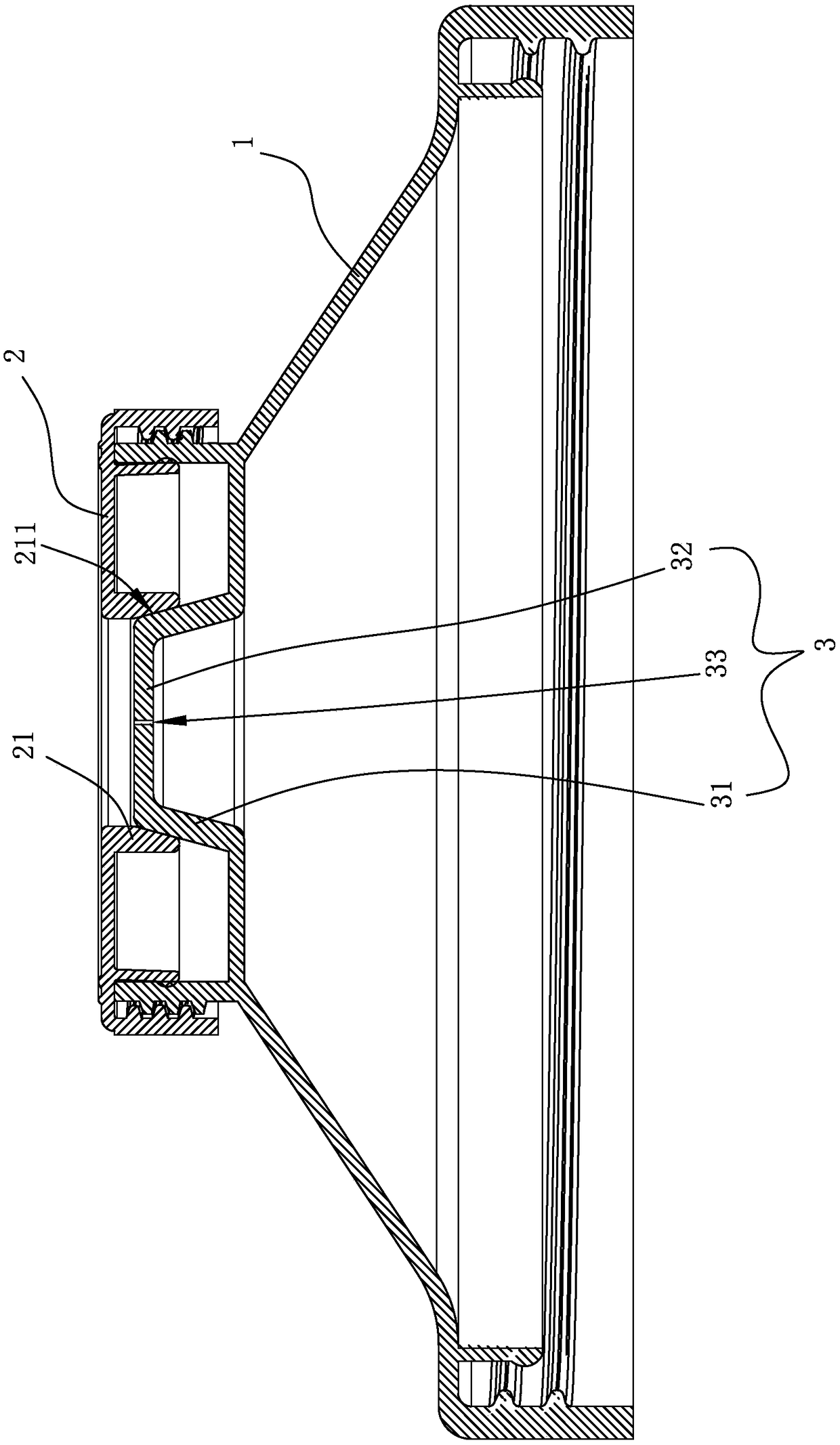

[0039] Such as figure 1 and figure 2 As shown, a bottle cap with automatic pressure relief in Embodiment 1 includes a base 1 connected to the opening of the container and an upper cover 2 connected to the base 1, and the outer side of the upper cover 2 is threaded on the base 1 Above, the base 1 is provided with a pressure relief structure 3, the pressure relief structure 3 is a trumpet-shaped structure with a small upper end and a larger lower end, and includes a conical connecting portion 31 and a circle connected to the upper end of the conical connecting portion 31. Shaped connecting portion 32, the circular connecting portion 32 is provided with a pressure relief slit 33 connecting the inner cavity of the container and the outside world, the pressure relief slit is to use a sharp knife to cut a hole on the circular connecting portion 32, When the pressure in the container is small, the pressure relief notch remains sealed. When the pressure of the container exceeds a ce...

Embodiment 2

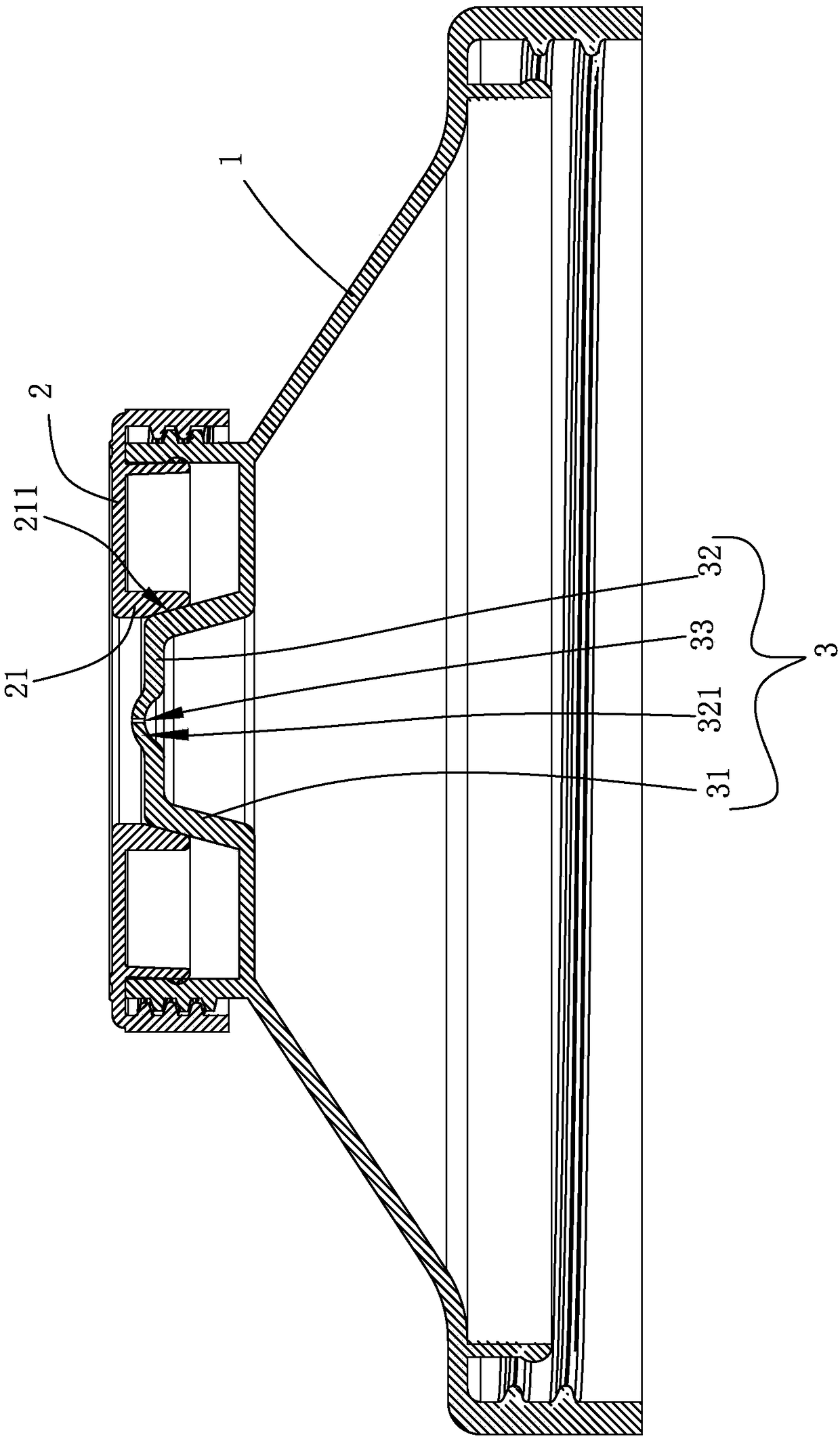

[0041] Such as image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that on the basis of Embodiment 1, an upwardly arched curved transition portion 321 is provided at the circular connection portion 32 and at the pressure relief slit 33, so The above-mentioned pressure relief slit 33 is arranged on the top of the curved transition portion 321 so that the pressure relief slit 33 remains in a sealed state; Provide greater extrusion force and improve the sealing effect of the pressure relief notch 33 .

Embodiment 3

[0043] Such as Figure 4As shown, a bottle cap that can automatically release pressure in embodiment 3 includes a base 1 connected to the opening of the container and an upper cover 2 connected to the base 1, and the outer side of the upper cover 2 is threaded on the base 1 Above, the upper cover 2 is provided with a pressure relief structure 3, the pressure relief structure 3 is a trumpet-shaped structure with a large upper end and a smaller lower end, and includes a conical connecting portion 31 and a conical connecting portion 31 connected to the lower end. Circular connecting portion 32, said circular connecting portion 32 is provided with a pressure relief slit 33 connecting the inner cavity of the container with the outside world, and the pressure relieving slit is to use a sharp knife to cut a hole on the circular connecting portion 32 When the pressure in the container is small, the pressure relief notch remains sealed. When the pressure in the container exceeds a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com