Anti-blowout line pole hoisting frame

A technology of explosion-proof tire and hoisting frame, which is applied to cranes and other directions, can solve problems such as low efficiency, waste of manpower, and difficulty in lifting, and achieve the effects of small footprint, simple structure and manpower saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

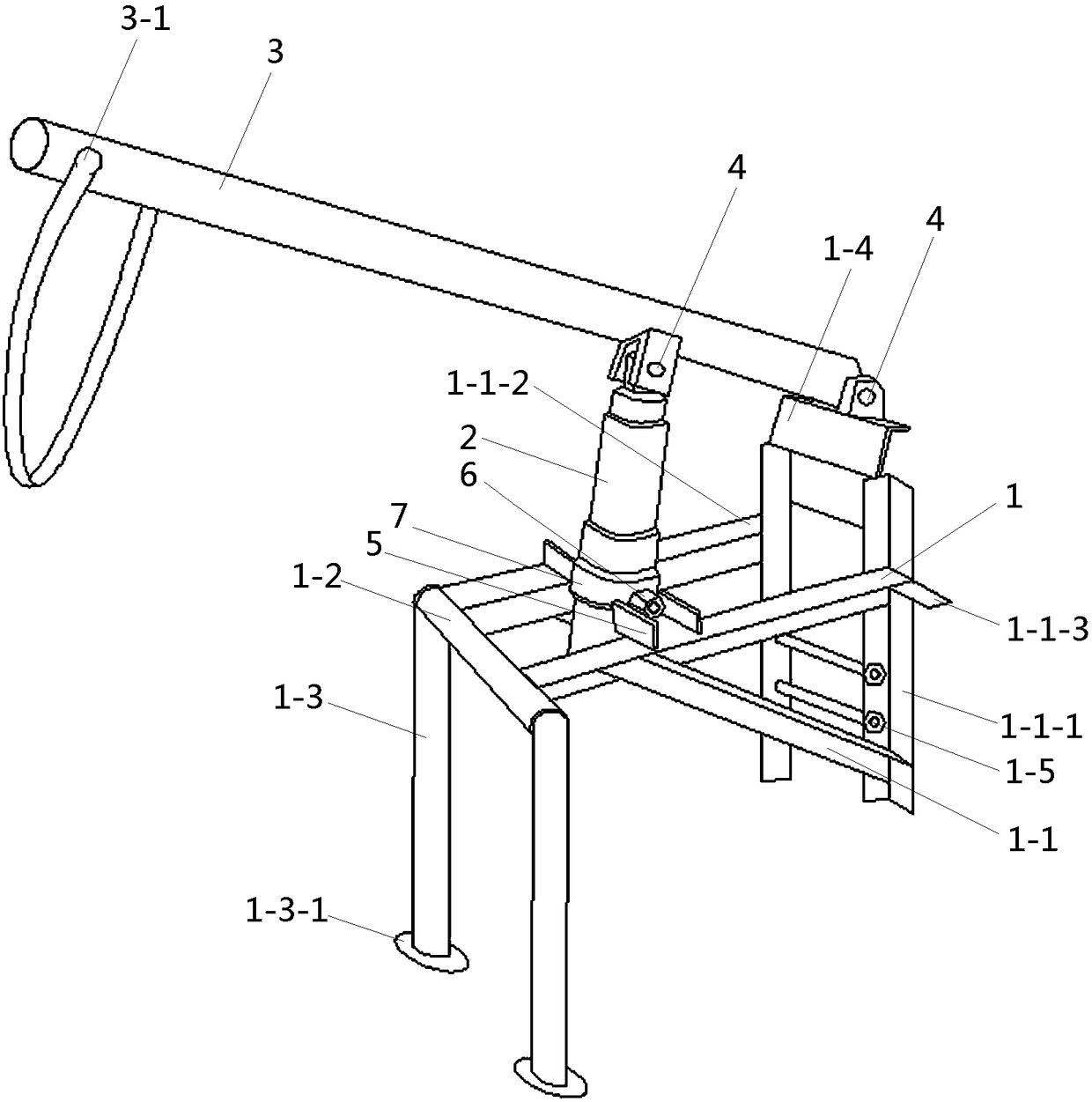

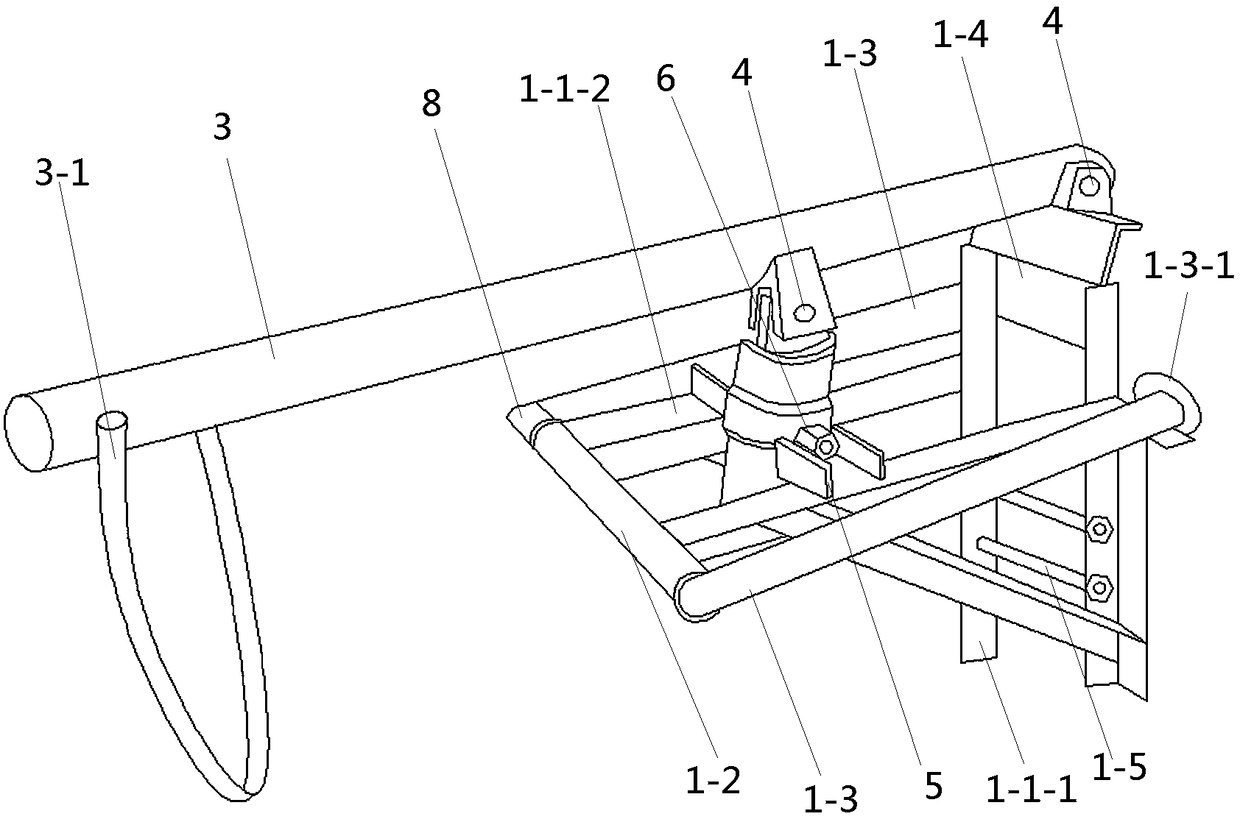

[0015] Embodiment 1, a kind of run-flat tire wire rod hoisting frame, such as figure 1 As shown, it includes a bracket 1, a hydraulic telescopic cylinder 2 connected to the bracket 1, and a lifting rod 3, and the front end of the lifting rod 3 is connected with a lifting wire rope 3-1. Support 1 provides supporting force for hydraulic telescopic cylinder 2, hydraulic telescopic cylinder 2 is used for lifting and lowering lifting rod 3, and the wire rope 3-1 at the front end of lifting rod 3 is used for lifting common utility pole. On the whole, although the above structure is simple and easy to implement, the present invention cleverly solves a series of problems in the prior art through structure refinement and application in specific scenarios.

[0016] The support 1 and the vehicle frame carrying a plurality of utility poles are jointly connected at the trailing end of the tractor tail, and the oil port of the hydraulic telescopic cylinder 2 is connected with the hydraulic ...

Embodiment 2

[0019] Embodiment 2, a kind of run-flat tire wire rod hoisting frame, the hinge structure of the base of the hydraulic telescopic cylinder 2 and the horizontal beam 1-1-2 of the tripod 1-1 includes a U-shaped groove 5 and a rotating sleeve 6, U There are two U-shaped grooves 5, and the two U-shaped grooves 5 are symmetrically fixedly connected to the upper surface of the horizontal beam 1-1-2, and the two U-shaped grooves 5 are welded with rotating sleeves 6 at the ends close to each other. The base of the hydraulic telescopic cylinder 2 is provided with a fixed flange 7 , and the oil port is located in a rotating column vertically passing through the fixed flange 7 , and the rotating column is rotatably connected with the rotating sleeve 6 . The oil port of the hydraulic telescopic cylinder is rotatably matched with the rotating sleeve in the U-shaped groove, which is not only simple in structure, but also convenient and practical.

[0020] Other structures of this embodiment...

Embodiment 3

[0021] Embodiment 3 is a hoisting frame for run-flat tire poles. The horizontal bar 1-2 is a hollow tube, and a horizontal core column 8 is inserted in the hollow tube, and the two ends of the horizontal core column 8 protrude from the hollow tube. Two swivel legs 1-3 are provided, and the two swivel legs 1-3 are fixedly arranged at the end of the horizontal stem 8 . The horizontal bar is designed as a hollow tube, which not only bears the force evenly, but also facilitates the integrated design with the rotating outrigger, which simplifies the structure and facilitates the rotation.

[0022] Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com