Textile equipment with heat dissipation function

A technology of textile equipment and functions, applied in the field of textile equipment with heat dissipation function, can solve the problems of no heat dissipation device, cumbersome operation, easy damage, etc., and achieve the effects of prolonging service life, improving safety and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

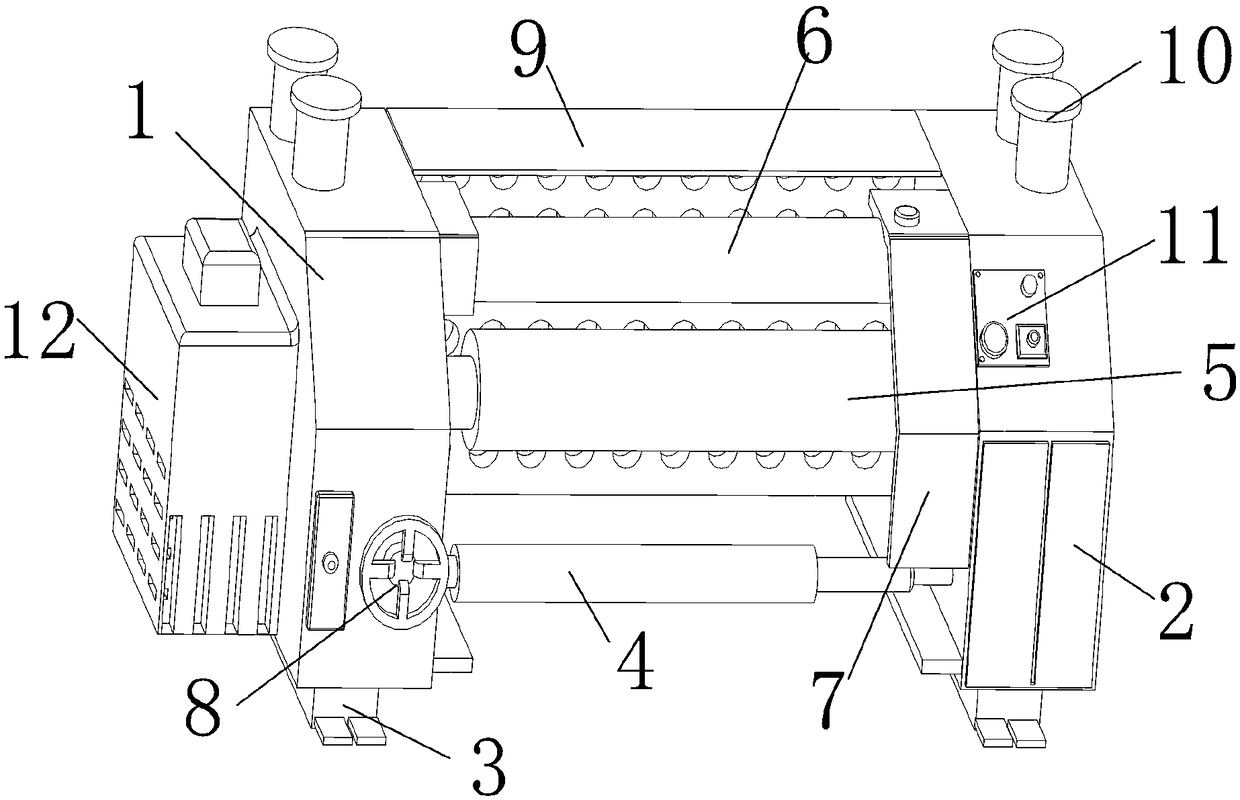

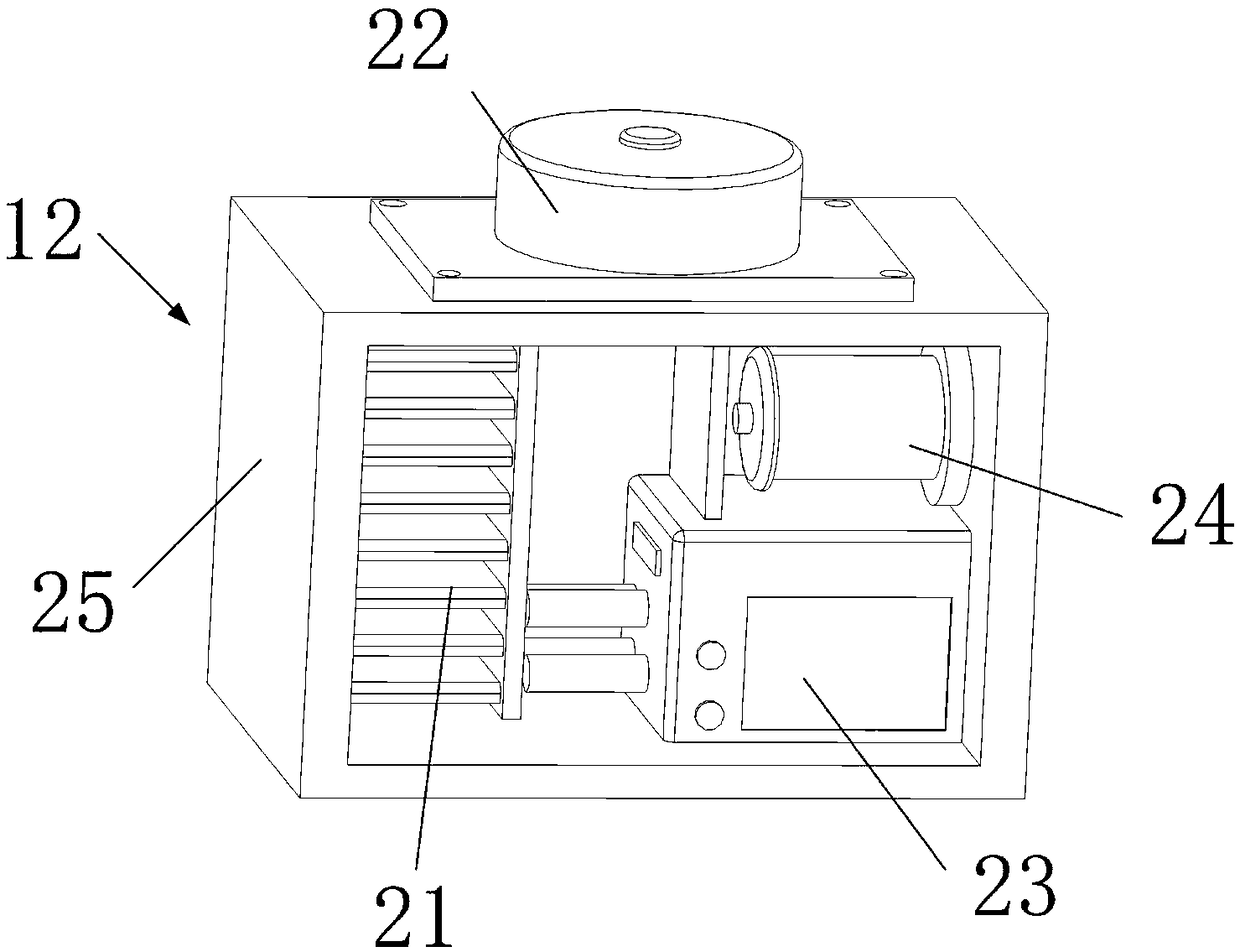

[0015] like Figure 1 to Figure 2 As shown, the textile equipment with heat dissipation function of the present invention includes a left textile machine platform 1, a right textile machine platform 2, a base 3, a cloth rolling rod 4, a cloth inspection rod 5, a spreading rod 6, a cloth inspection rod protection cover 7, a cloth rolling Rod regulating valve 8, rear baffle plate 9, balance column 10, control button 11, heat dissipation mechanism 12, one end of the left textile machine platform 1 is connected with the base 3, the right textile machine platform 2 is located under the balance column 10, and the base 3 is located at the right Below the textile machine table 2, the cloth rolling rod 4 is located under the cloth inspection rod 5, and the cloth inspection rod 5 is located in fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com