Double-column super-high rigid frame pier connected by multi-heavy steel members

A double-column, rigid-frame pier technology, applied in the field of double-column ultra-high rigid-frame piers, to achieve the effects of clear structural force transmission, good compressive performance, and enhanced seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

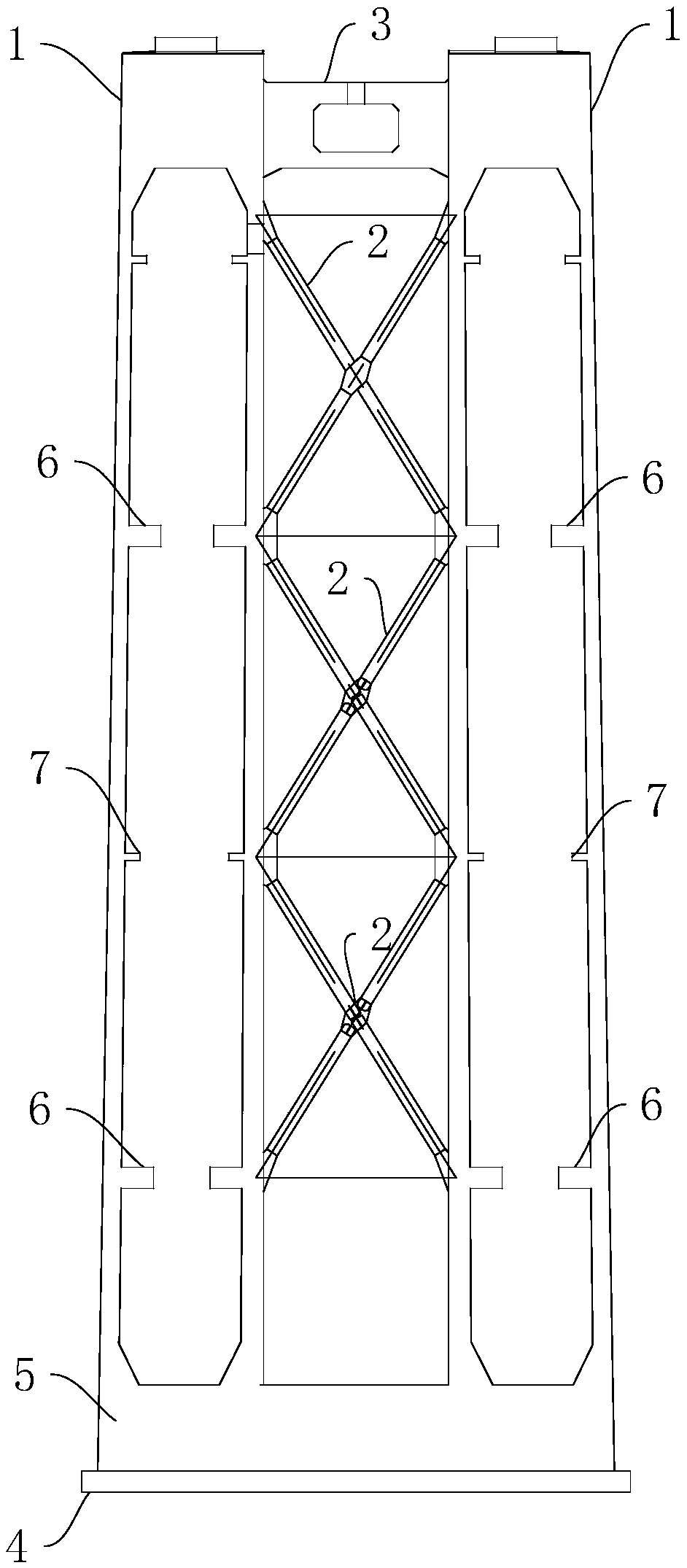

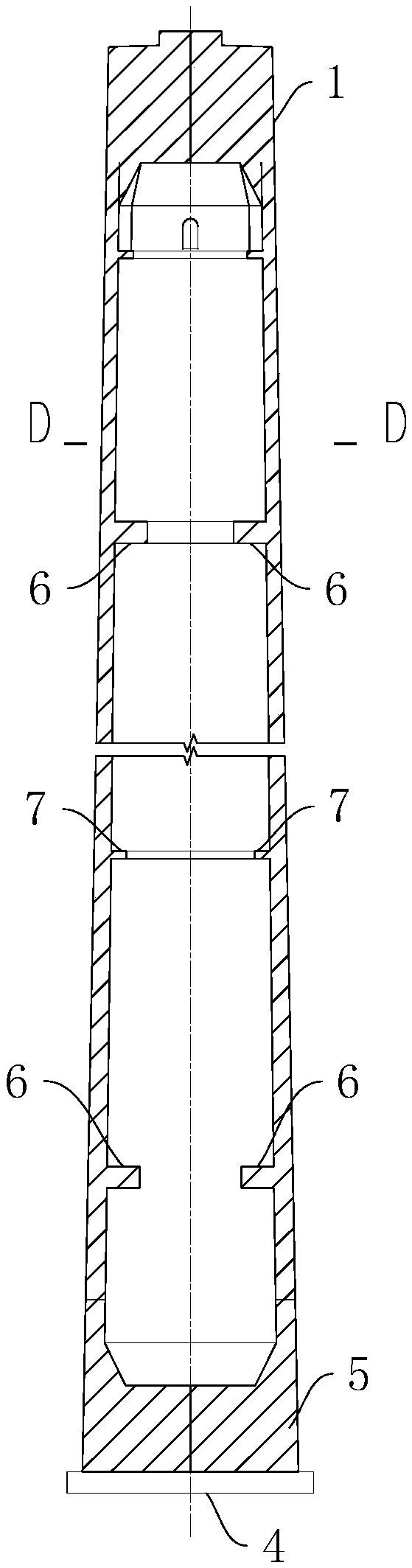

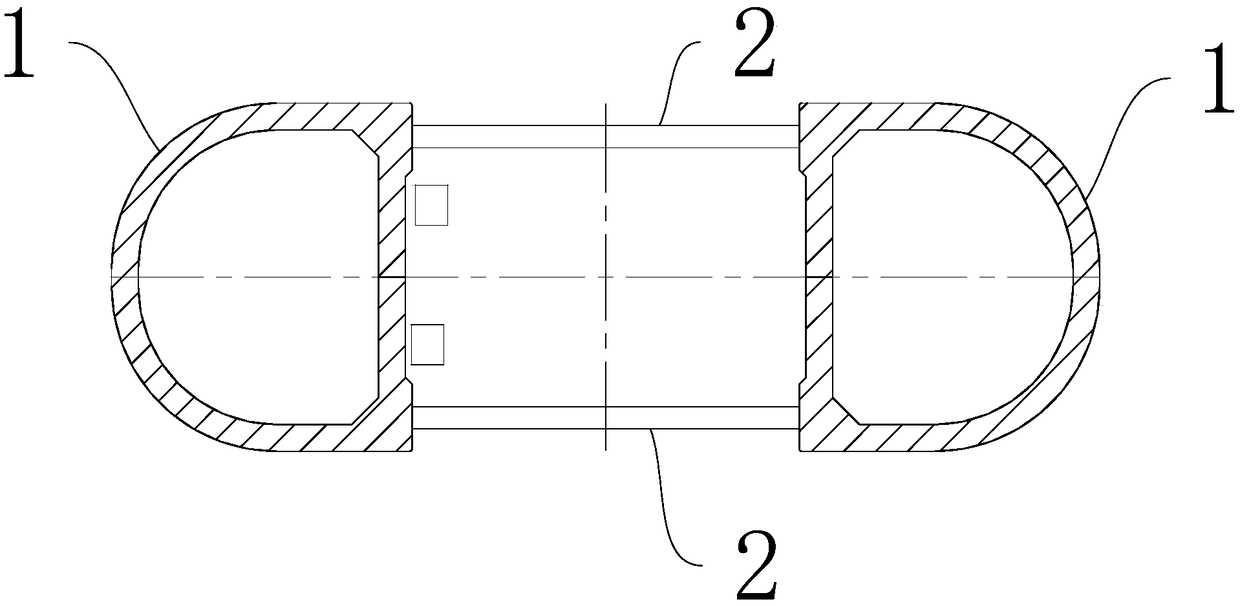

[0031] Double-column ultra-high rigid frame pier connected by multiple steel members, including pier column 1 and cross-connection member 2 used for connection between pier columns 1, cross-connection member 2 is located between pier columns 1, and cross-connection member 2 passes through The plane formed by the centerline of the connected pier column 1 is X-shaped, so as to convert the bending moment acting on the pier into tensile and compressive axial loads.

[0032] During work, the bending moment acting on the pier column 1, such as the bending moment caused by an earthquake, can be transmitted to the adjacent pier column 1 by the cross-link member 2, and the bending moment can be further converted into tension and compression through the X-shaped structure. In this way, the pier column 1 can give full play to the performance of bearing tension and compression loads, thereby enhancing the seismic performance of the double-column ultra-high rigid frame pier. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com