External corner seam beautifying method

A technology of gaps and outside corners, applied in the field of ceramic tile beauty seams, can solve the problems of difficult cleaning, affect the appearance, skewed tapes, etc., to achieve the effect of improving efficiency, convenient operation, and smooth tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A method for beautifying seams at external corners, comprising the following steps:

[0032] 1) After cleaning the gaps of the tiles in the positive corners, use a tape roller for the beauty of the positive corners to roll the tape on the tile surfaces on both sides of the gaps;

[0033] 2) Inject the beautifying agent into the gap between the tiles that have been taped on both sides until the glue surface of the beautifying agent is 1-2mm higher than the surface of the tile;

[0034] 3) Use the edge-pressing ball to scrape the beautifying agent in the gap along the length direction of the gap until the highest point of the beautifying agent glue surface in the gap is flush with the upper edge of the gap;

[0035] 4) Tear off the tape that has been covered with residual beautifying agent on both sides of the gap and wait for the beautifying agent to solidify.

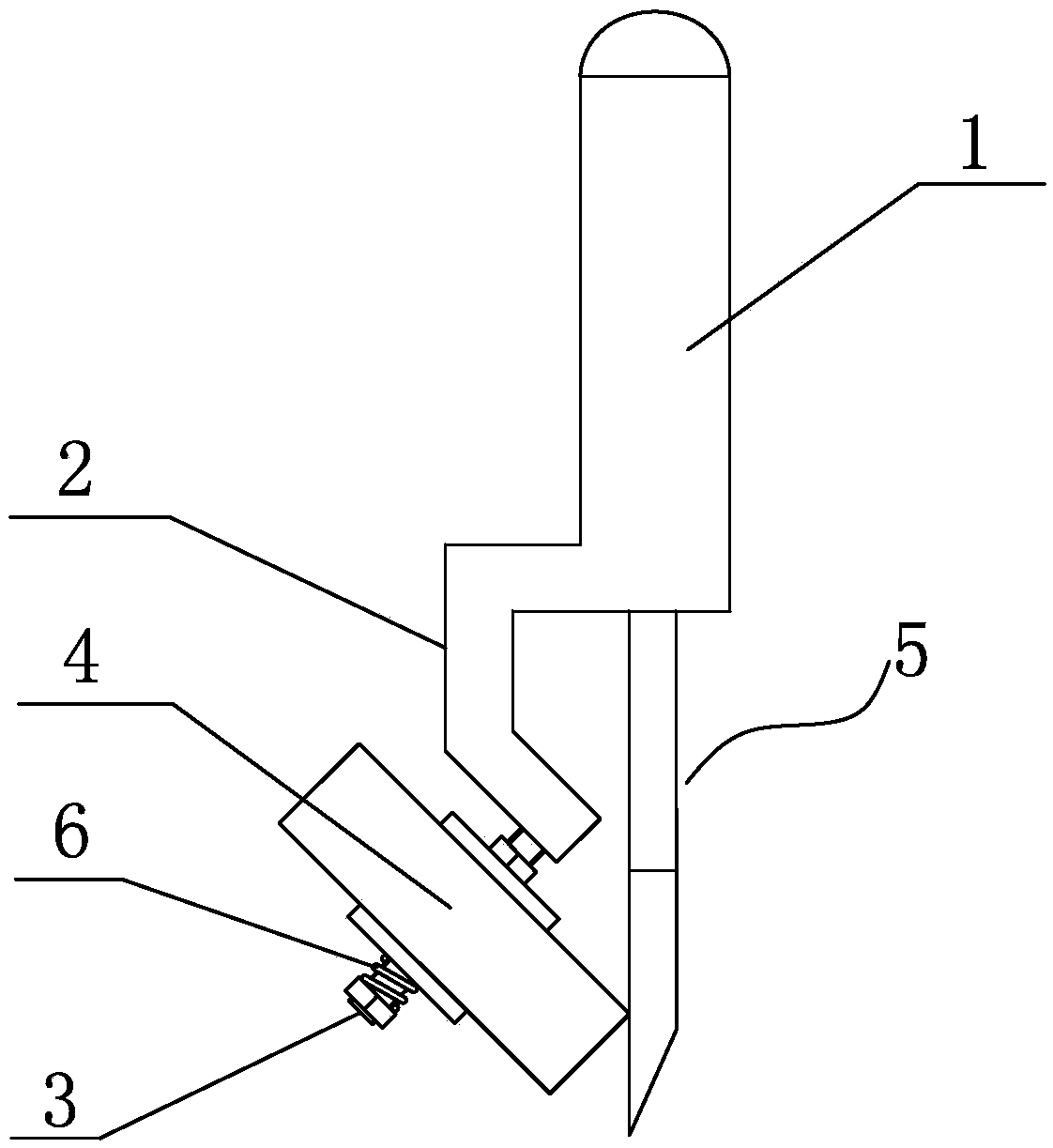

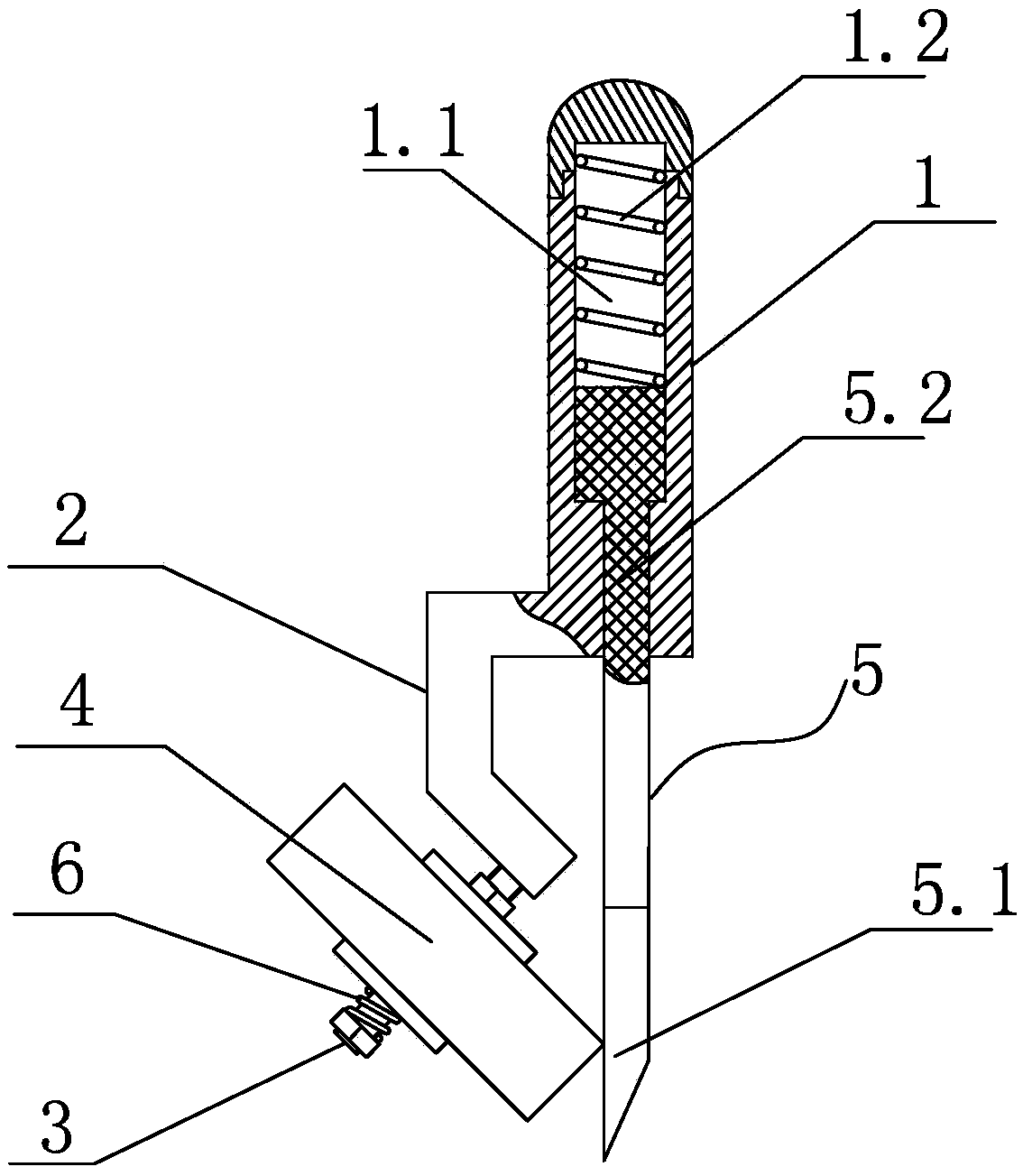

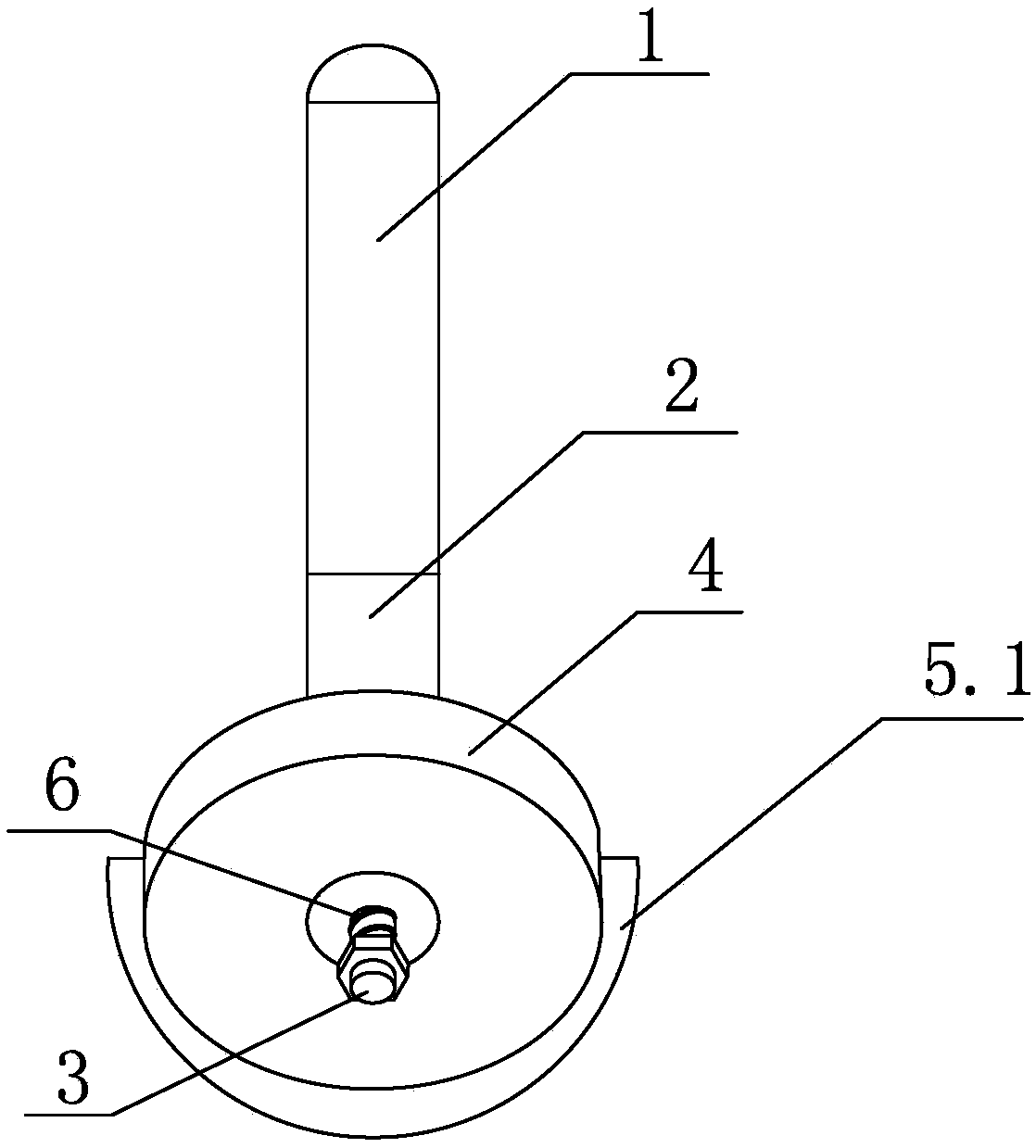

[0036] Such as Figure 1-6 As shown, the tape roller for positive seams includes a handle 1 and a fixed arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com