Square bar ball universal shaft coupler

A technology of couplings and universal joints, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of structural defects and poor maintenance performance of universal couplings, and achieve low contact stress, Flexible and well-structured joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

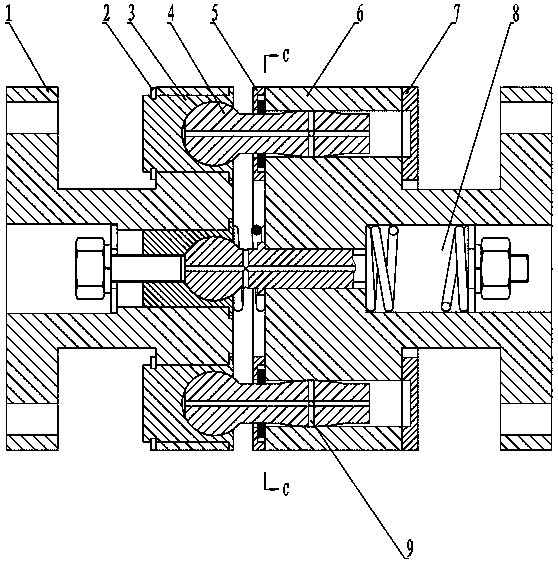

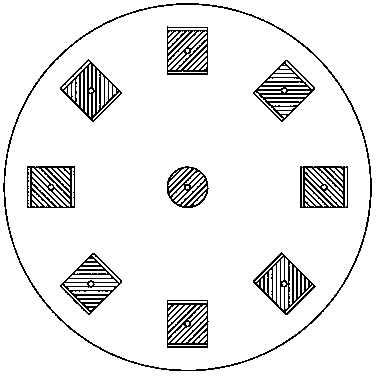

[0022] In the embodiment of the present invention, the universal joint of the square bar ball universal coupling is composed of ball joint 1, square joint 6, split ball seat 3, ball joint square bar 4 and center positioning assembly 8 and other main components. Composition, such as figure 1 shown. The ball head of the ball head square rod 4 can rotate freely in the split ball seat 3, which forms a hinge point, and the square rod of the ball head square rod 4 can move along the center of the square hole in the square hole of the square head receiver 6. The wire can move in a straight line and can rotate in a small angle (only a small angle), which can ensure the flexibility of the joint.

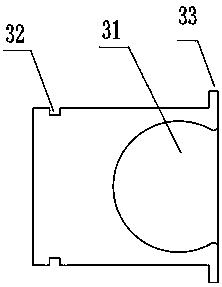

[0023] The ball seat of the square rod ball universal coupling joint is split type, which is composed of two split ball seats 3 and a snap ring 2. The split ball seat 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com