Bypass valve system for coke oven flue gas purification device

A coke oven flue gas and bypass valve technology, which is applied to furnaces, furnace components, waste heat treatment, etc., can solve the problems of increasing the difficulty of flue gas purification facilities and not considering the reserved flue gas interface, so as to achieve compact layout and reduce Construction time and the effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

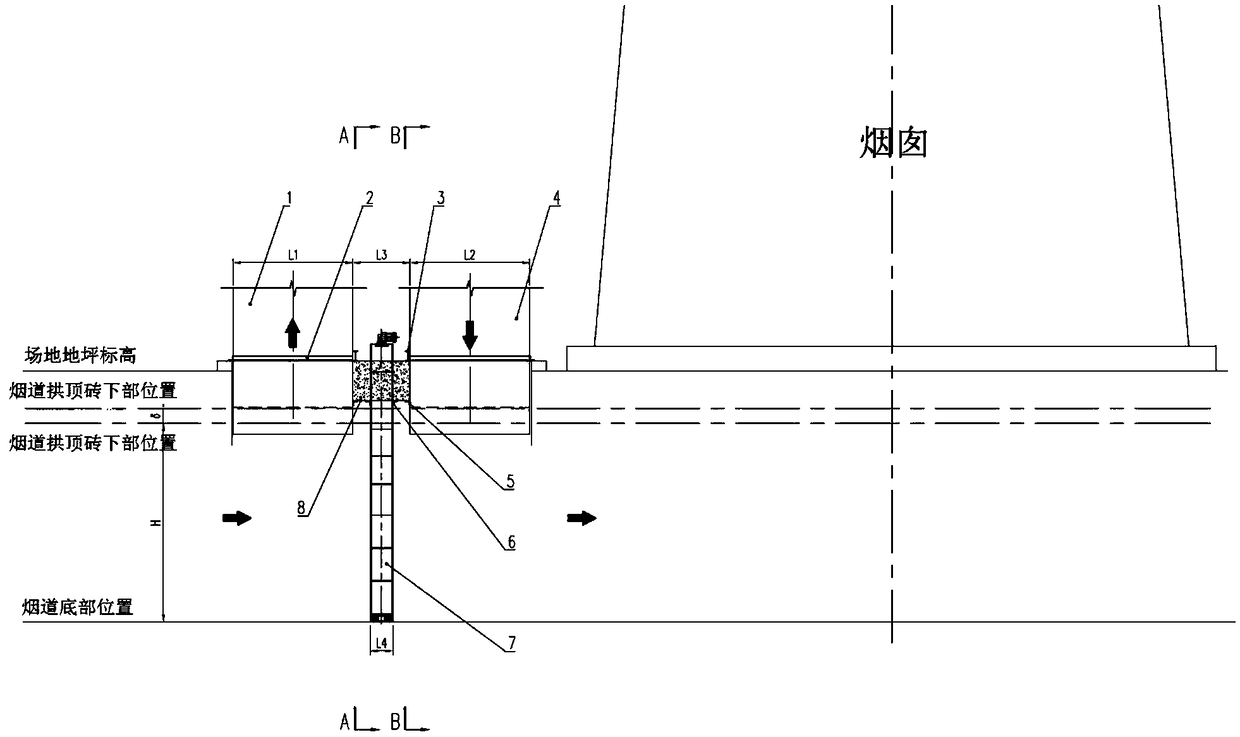

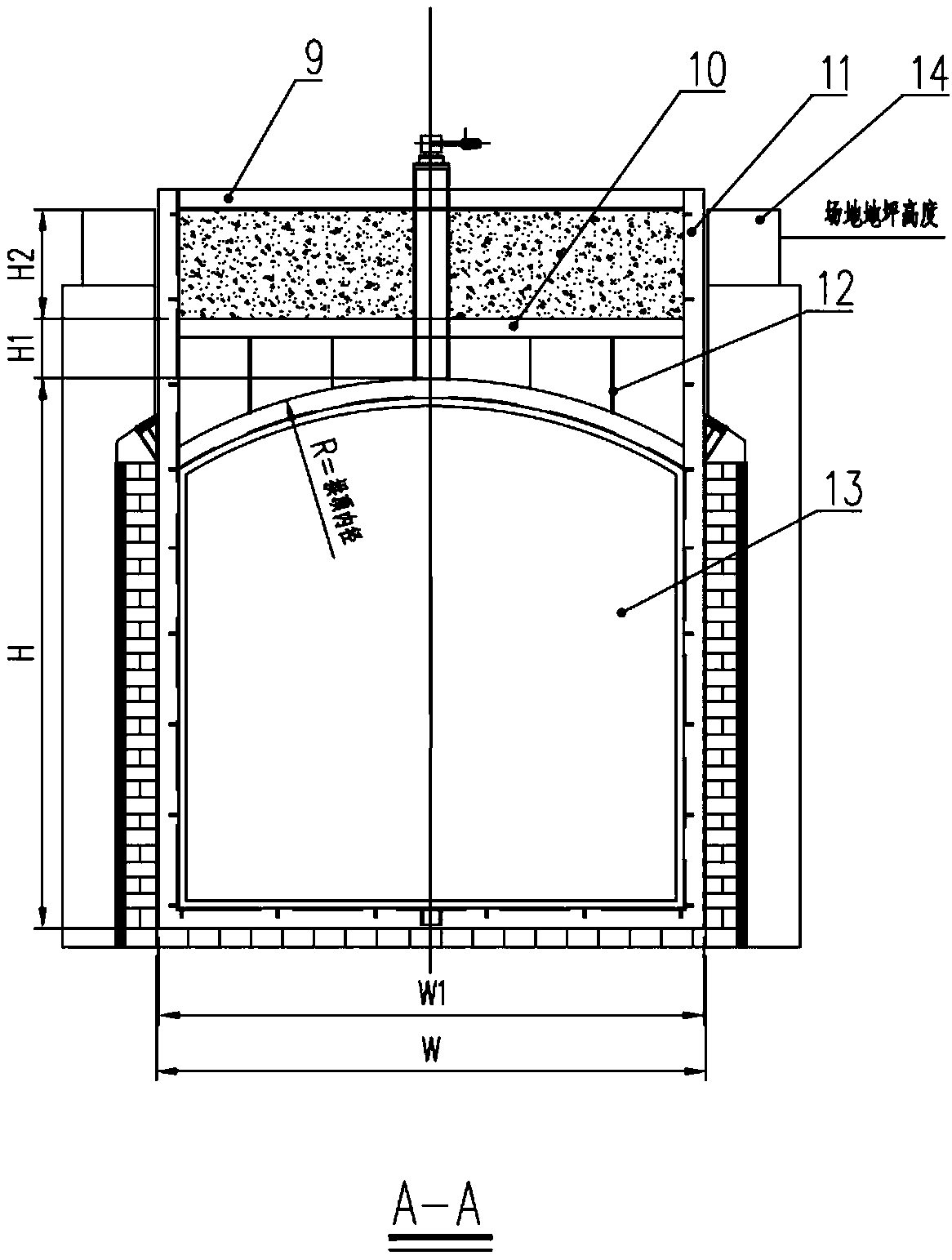

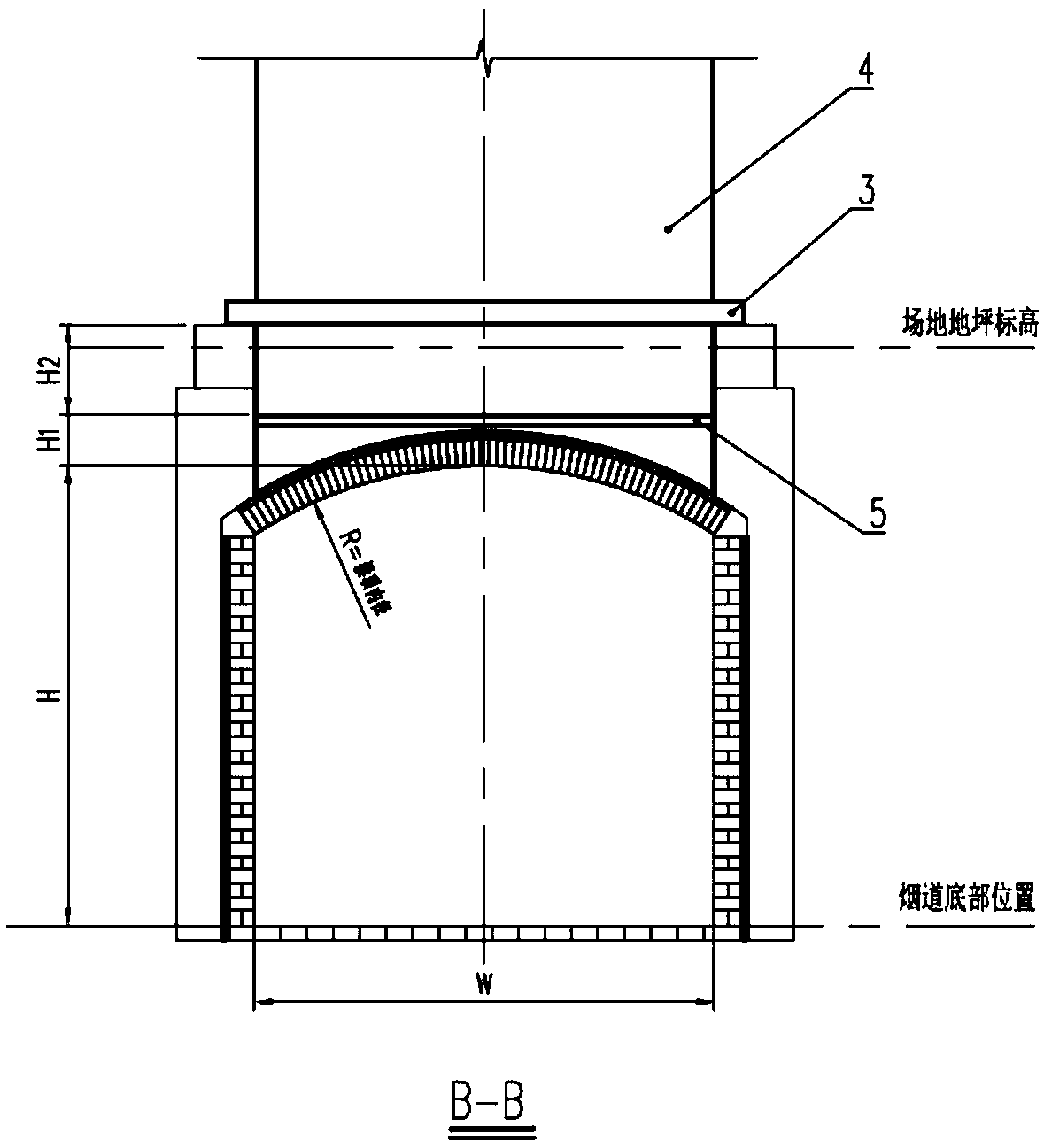

[0028] A coke oven flue gas purification device bypass valve system, the bypass valve system includes an original flue 1, a clean flue 4, a bypass flue valve 7 and a sealing device, and the bypass flue valve 7 is set On the combined flue of the coke oven, and cut off the combined flue of the coke oven, the original flue 1 and the clean flue 4 are arranged on both sides of the bypass flue valve 7, and the sealing device is arranged for the original The seal between flue 1, clean flue 4, bypass flue valve 7, and coke oven summary flue; the flue gas is led to the flue gas purification device through the original flue 1 and sent back to the flue gas purification device after reaching the standard Describe clean flue 4, directly discharge by chimney.

[0029] The side of the bypass flue valve 7 is provided with a bypass valve side bracket 6, the side of the original flue 1 close to the side of the bypass flue valve 7 is provided with a flue side bracket 5, and the clean flue 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com