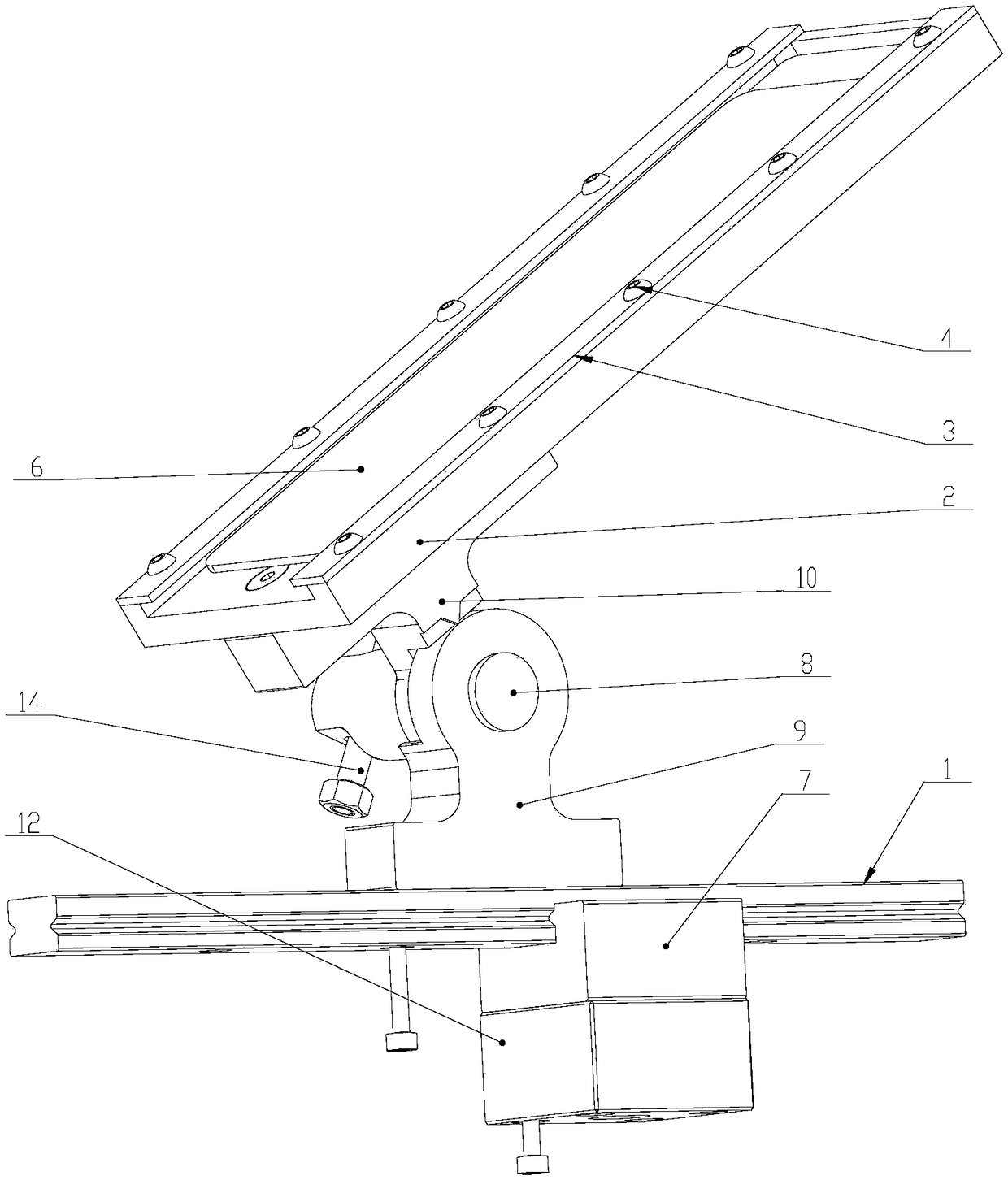

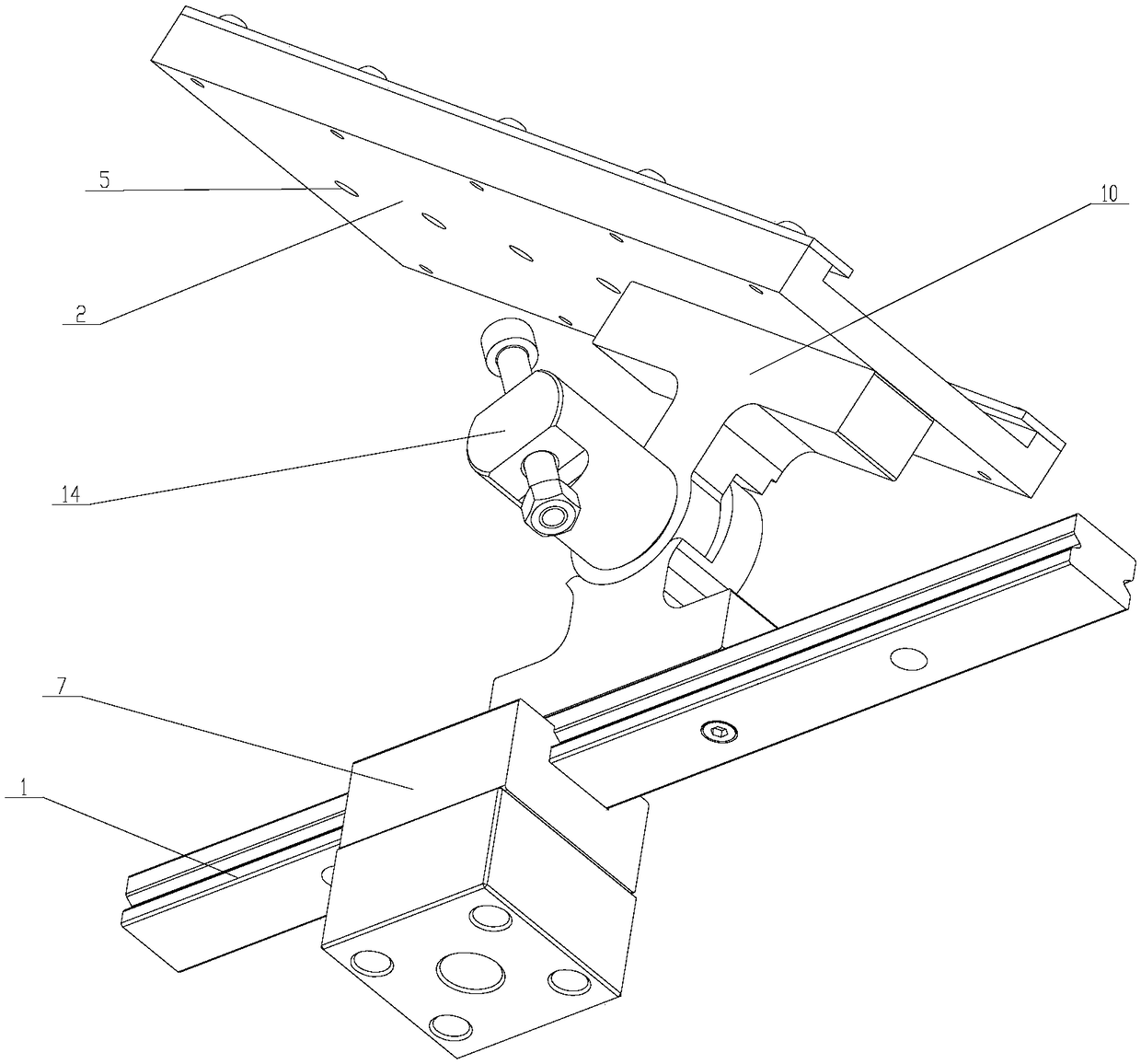

Method and clamp for testing anti-stripping strength of cigarette water-soluble adhesive on cigarette paper

A water-based adhesive and anti-peeling technology, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of not being able to characterize the peeling strength of adhesives, and achieve the effects of promoting technological progress, reducing defective rate, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Get 10 pieces of test samples that the same kind of cigarette packaging glue-cigarette carton paper matches, use the fixture of the present invention, carry out the upper machine test of anti-45 ° and 120 ° (each doing 5 pieces) peel strength respectively, its test data The average values are 5.836kN / m and 7.208kN / m respectively. Through the data analysis of the above peel strength, the strength of this kind of cigarette packaging glue meets the mechanical properties and the national standard or industry standard, and then the technicians used this glue in the actual cigarette production and packaging process, and found no displacement of the lap joint, Quality problems such as cracking, warping, and air leakage show that this method can well characterize the actual strength of the non-90° peeling force damage on the adhesive surface after the use of water-based adhesive for cigarettes in the cigarette production process.

Embodiment 2

[0047] Get 10 pieces of test specimens that are matched by the same kind of lapping glue-cigarette paper, use fixture of the present invention, carry out the on-machine test of anti-75 ° and 108 ° (each doing 5 pieces) peel strength respectively, the average value of its test data They are 2.957kN / m and 5.385kN / m respectively. Through the data analysis of the above peel strength, the strength of this lapping glue meets the mechanical properties and the national standard or industry standard, and then the technicians used this glue in the actual cigarette production and packaging process, and did not find any lap joint displacement, Quality problems such as cracking, warping, and air leakage show that this method can well characterize the actual strength of the non-90° peeling force damage on the adhesive surface after the use of water-based adhesive for cigarettes in the cigarette production process.

Embodiment 3

[0049] 10 pieces of test samples matched by the same mouthpiece glue-tipping paper, use the fixture of the present invention to carry out the upper-machine test of the peel strength of 30 ° and 135 ° (each doing 5 pieces) respectively, and the average value of the test data They are 5.094kN / m and 6.243kN / m respectively. Through the data analysis of the above peel strength, the strength of this kind of mouth glue meets the mechanical properties and the national standard or industry standard, and then the technicians used this glue in the actual cigarette production and packaging process, and found no displacement of the lap joint, Quality problems such as cracking, warping, and air leakage show that this method can well characterize the actual strength of the non-90° peeling force damage on the adhesive surface after the use of water-based adhesive for cigarettes in the cigarette production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com