Heat dissipation device for display

A heat dissipation device and display technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of heat dissipation material defects and application limitations of display heat dissipation devices, and achieve the effect of ultra-thin structure and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

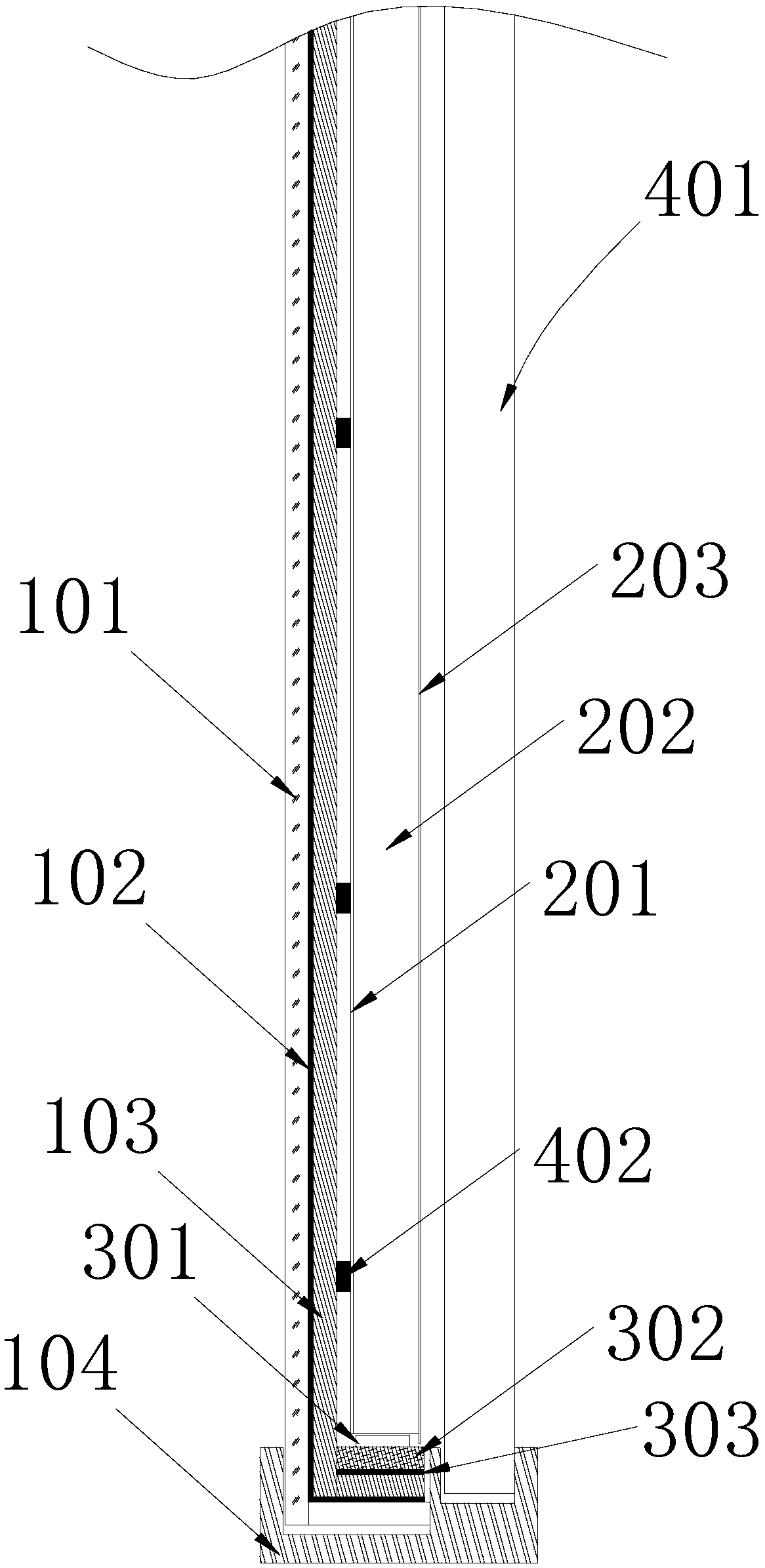

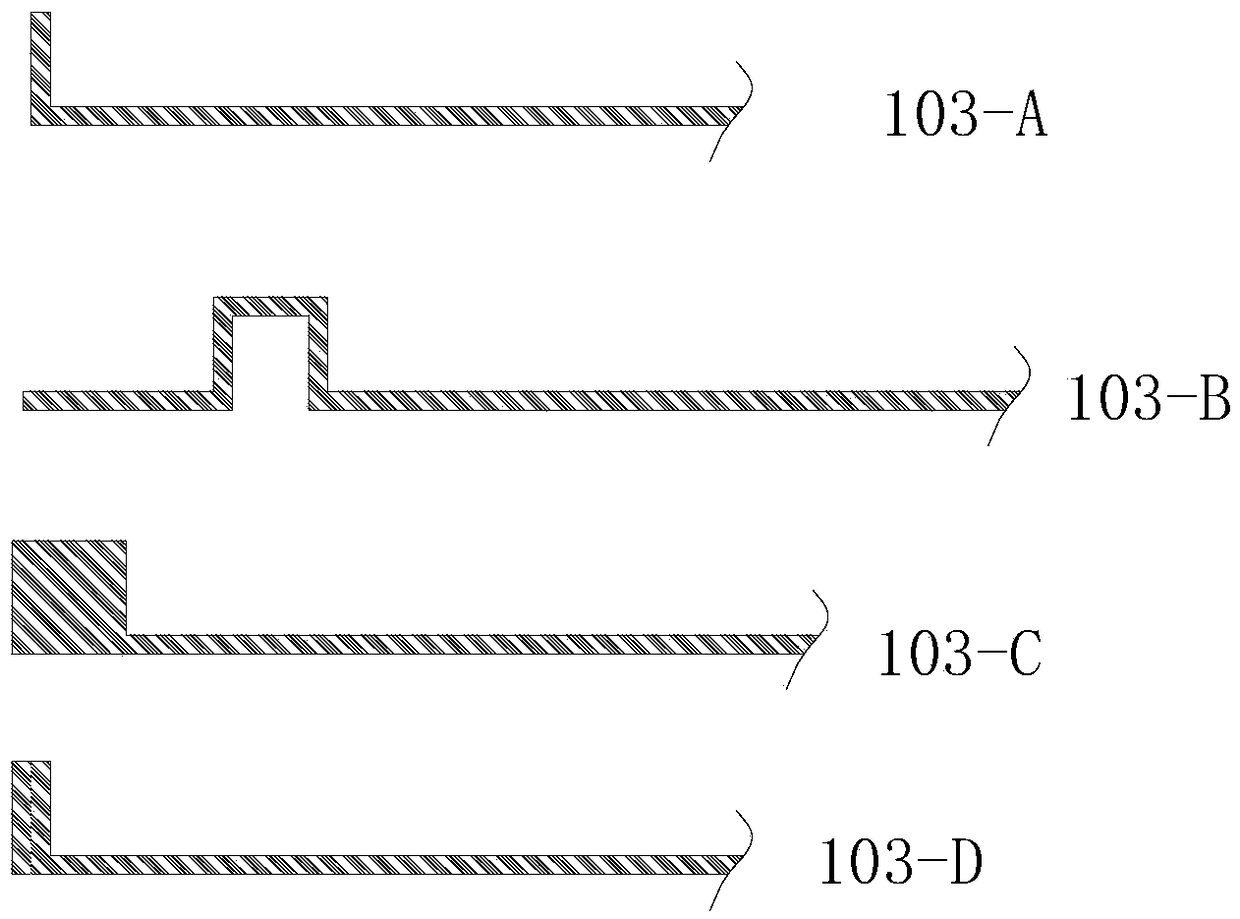

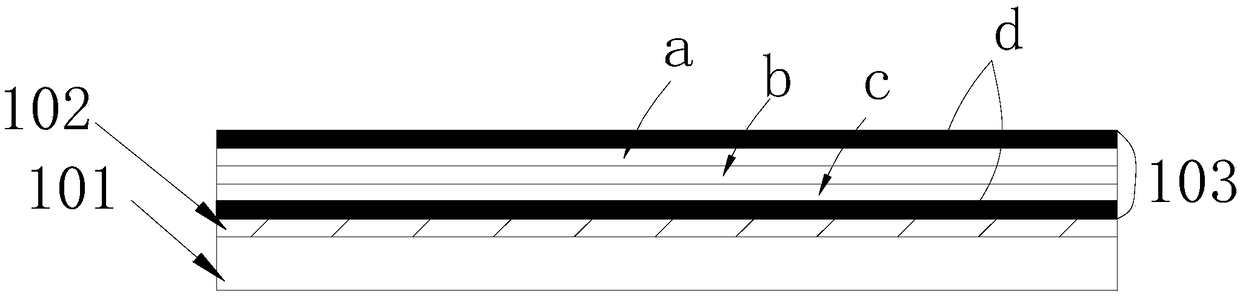

[0021] Such as figure 1 As shown, the display heat dissipation device of the embodiment of the present invention includes a backplane 101, an adhesive layer 102, a heat dissipation plate 103, a support assembly 402, a reflection sheet 201, a light guide plate 202, a diffusion sheet 203, a display unit 401, and a side-entry LED light source. 301, LED light circuit board 302, LED light strip adhesive layer 303, back plate 101, adhesive layer 102, heat dissipation plate 103, support assembly 402, reflection sheet 201, light guide plate 202, diffusion s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com