Vehicle anti-glare rear view mirror manufacturing method and vehicle anti-glare rear view mirror

A manufacturing method and rearview mirror technology, which is applied in the field of vehicle rearview mirrors, can solve the problems of colloid thickness rebound, box thickness unevenness, etc., and achieve the effects of preventing rebound, convenient curing, and good thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

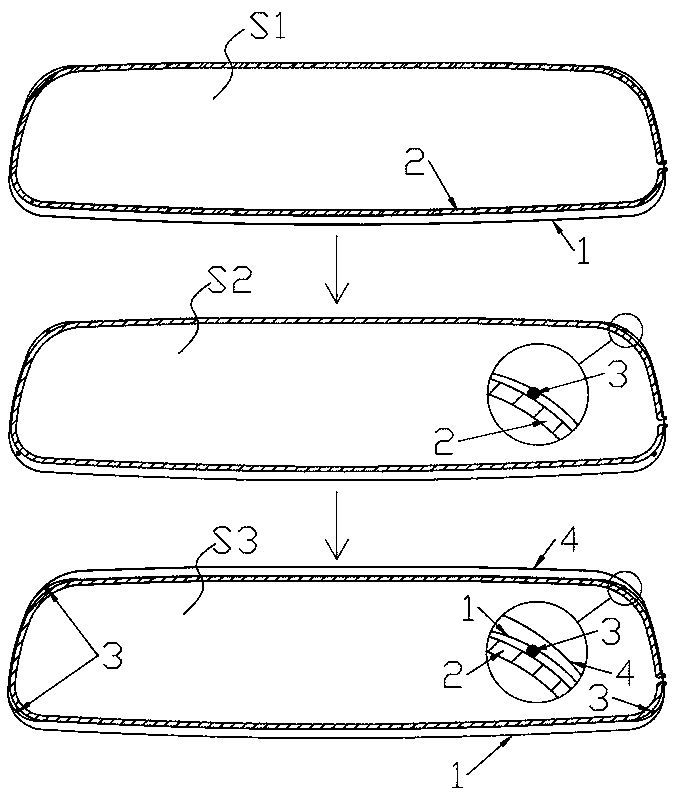

[0029] Such as figure 1 As shown, the embodiment of the present invention provides a method for manufacturing a vehicle-mounted anti-glare rearview mirror, comprising the following steps:

[0030] S1: Provide the lower functional substrate 1 and clamp it with the first bonding fixture, and apply heat-curable sealant 2 around the side of the lower functional substrate 1 with the conductive layer;

[0031] S2: Spot UV glue 3 on the four corners of the side of the lower functional substrate 1 with the conductive layer 5;

[0032] S3: Provide an upper functional substrate 4 and clamp it with the second bonding fixture, and attach the side of the upper functional substrate 4 with the conductive layer 5 to the side of the lower functional substrate 1 with the conductive layer 5 The position of the bonding equipment corresponding to the UV glue 3 is transparent or avoids the air;

[0033] S4: Use UV light to cure UV glue 3 immediately after bonding;

[0034] S5: The first and seco...

Embodiment 2

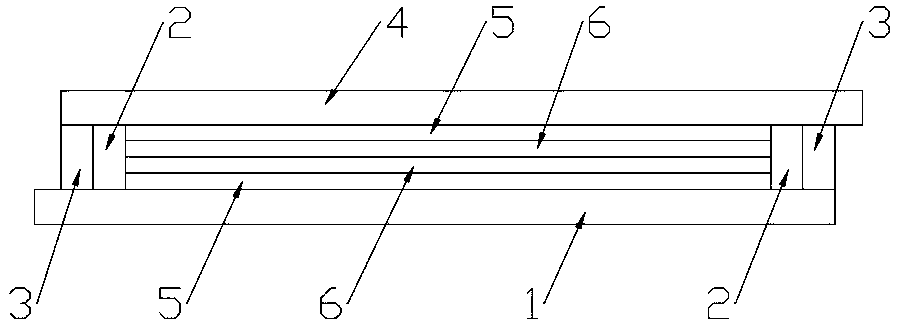

[0041] Such as figure 2As shown, the embodiment of the present invention provides a vehicle-mounted anti-glare rearview mirror, including a lower functional substrate 1 and an upper functional substrate 4 oppositely arranged, and the lower functional substrate 1 faces the upper functional substrate One side of 4 is surrounded by heat-curable frame glue 2, and UV glue 3 is provided at the four corners of the side of the lower functional substrate 1 facing the upper functional substrate 4, and the lower functional substrate 1 and the upper functional substrate 4 are bonded and fixed by UV glue 3 and thermosetting frame glue 2.

[0042] In the embodiment of the present invention, by setting a thermosetting frame glue 2 and a UV glue 3 on the lower functional substrate 1 at the same time, the rebound of the thermosetting glue 2 is effectively prevented, so that the lower functional substrate 1 and the upper functional substrate 4 are bonded together. The thickness uniformity aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com