Precise modeling method of gear considering microcosmic modification and actual machining error

A machining error, practical technology, applied in the field of gear modeling and machining, can solve the problem of not comprehensively considering the micro modification machining error and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

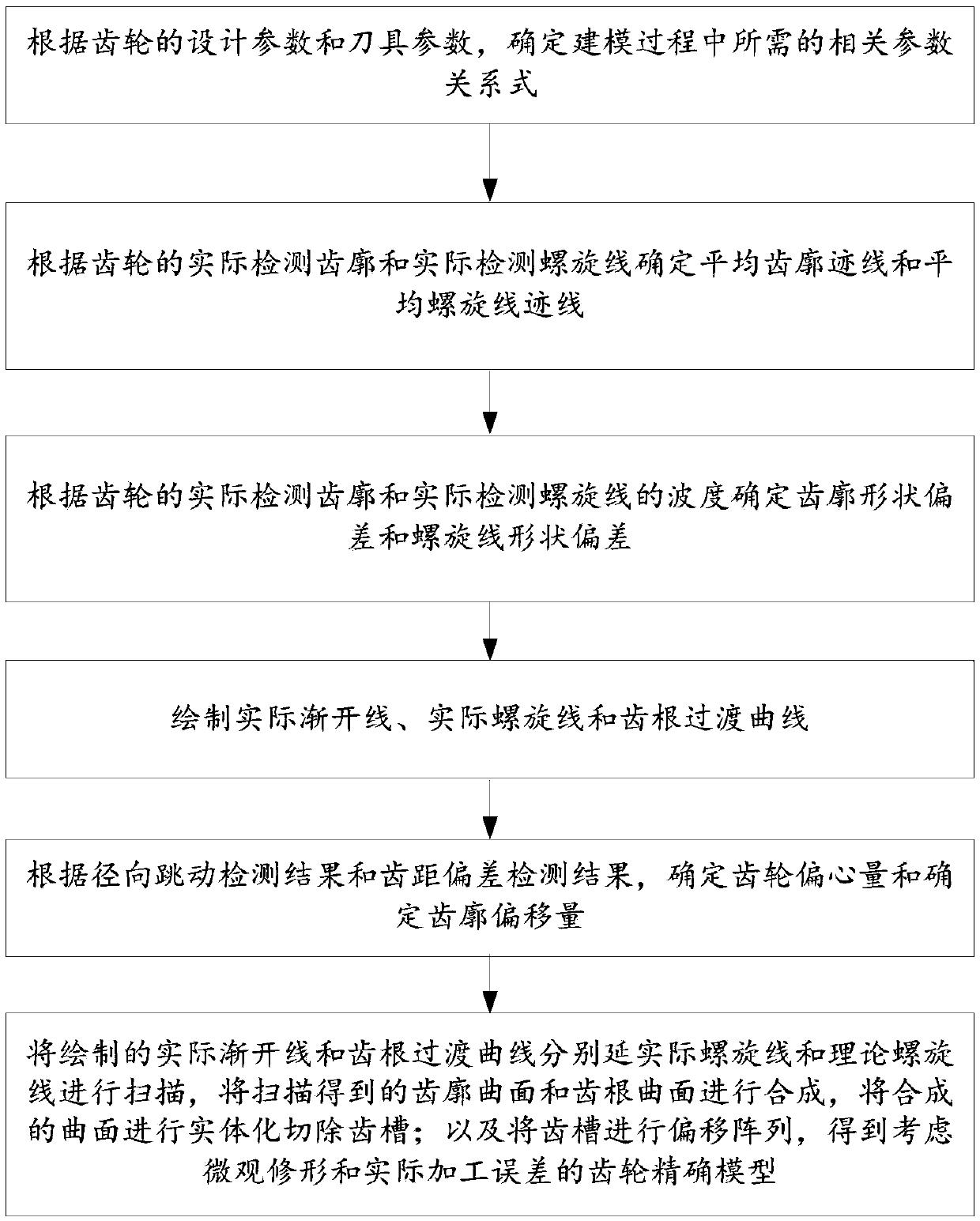

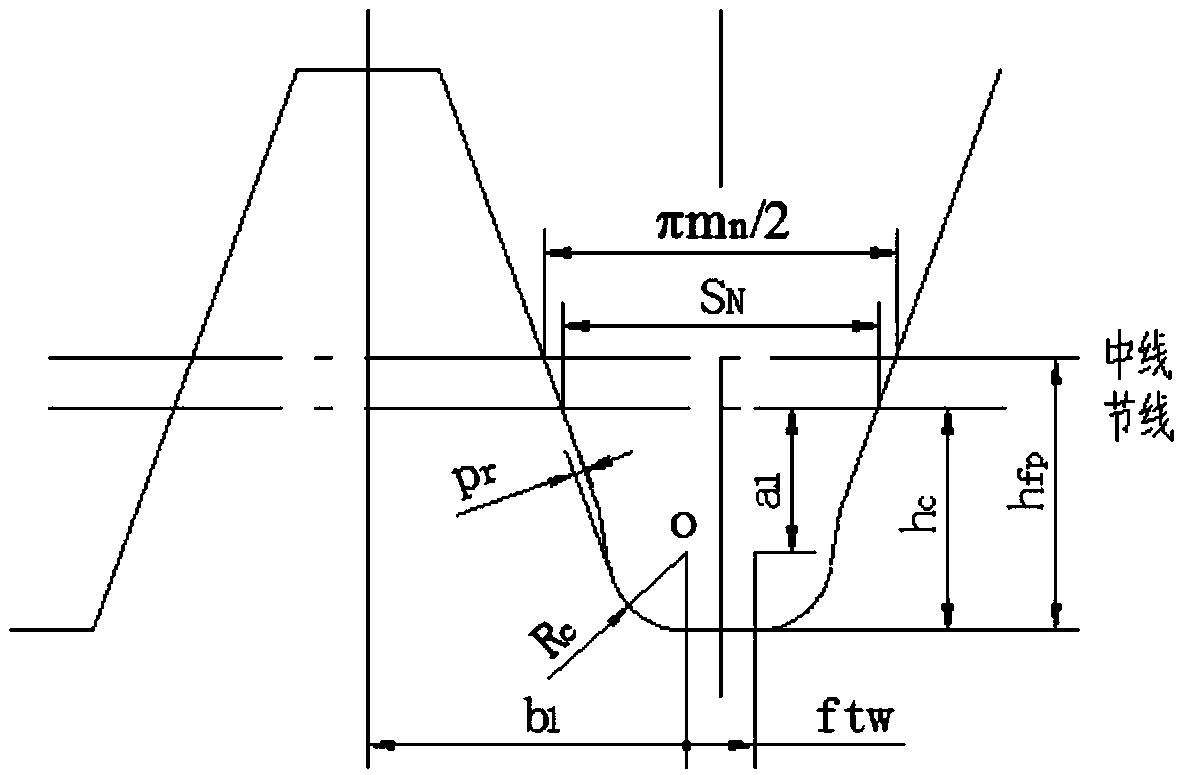

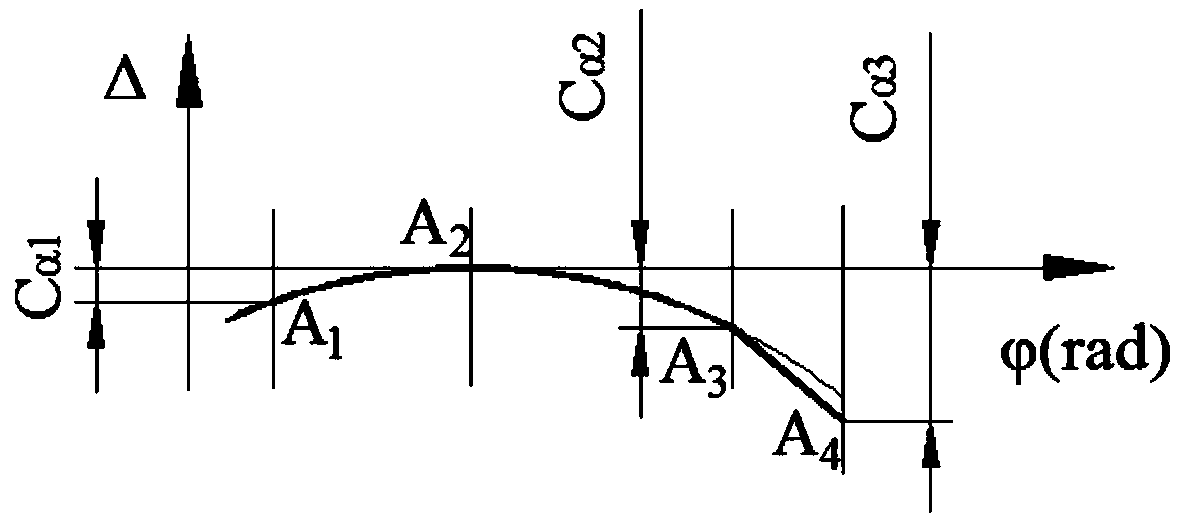

[0063] figure 1 Is a schematic flow diagram of a gear modeling method provided by an embodiment of the present invention; figure 2 It is a schematic diagram of tool structure parameters; image 3 It is a schematic diagram of the average tooth profile trace of the detection gear; Figure 4 It is a schematic diagram of the average spiral trace of the detection gear; Figure 5 It is a schematic diagram of the actual tooth profile trace of the detection gear; Image 6 It is a schematic diagram of the actual spiral trace of the detection gear; Figure 7 Is the actual involute diagram; Figure 8 It is a schematic diagram of the actual base circle helix of the right-handed gear; Picture 9 It is a schematic diagram of the actual base circle helix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com