Transparent X-ray shielding chamber

An X-ray and shielding room technology, which is applied in the field of X-ray radiation shielding devices, can solve problems such as insufficient safety, reduced work efficiency, and inconvenient picking/putting of inspected parts, so as to improve work efficiency and safety, reduce Difficulty of installation and replacement, effects of enhanced sealing and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The features and technical effects of the transparent X-ray shielding room of the present invention will be described below with reference to the accompanying drawings.

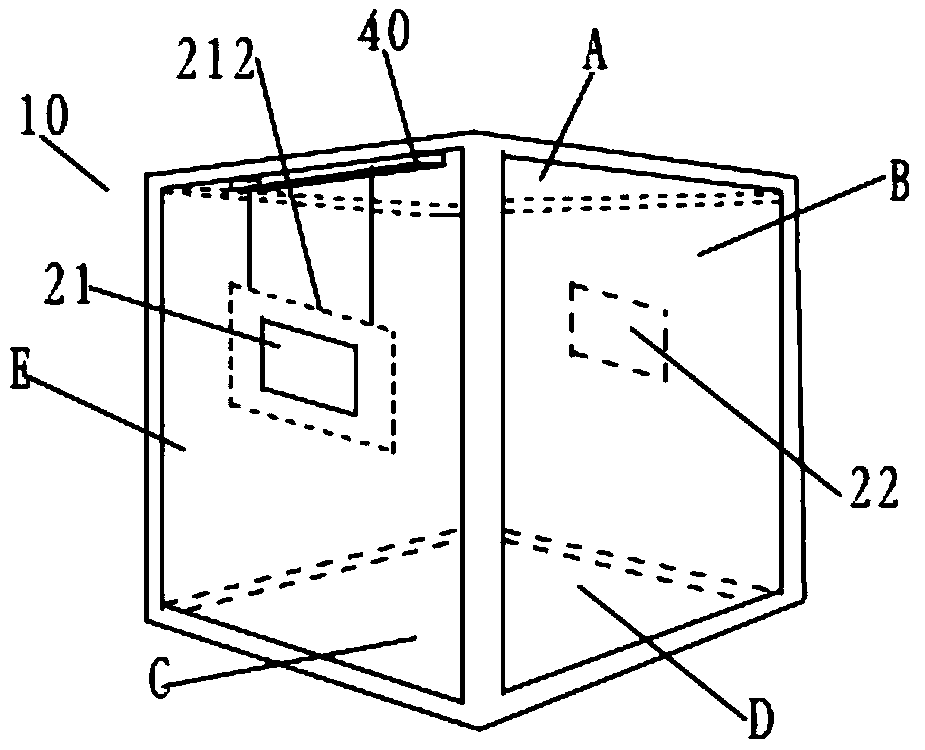

[0046] Such as figure 1 Shown is a transparent X-ray shielding room 1 of the present invention, which is installed on the ground of the room. The shielding room 1 is a rectangular lead room 10, which specifically includes a metal frame 11 and a lead glass plate 12. The metal frame 11 constitutes the frame outline of the rectangular lead room, and the lead glass plate 12 is embedded in the metal frame 11 to form a rectangular lead room 10. The 5 sides are all transparent, that is, the top surface A, the left side B and the right side C, the front side D and the rear side door E.

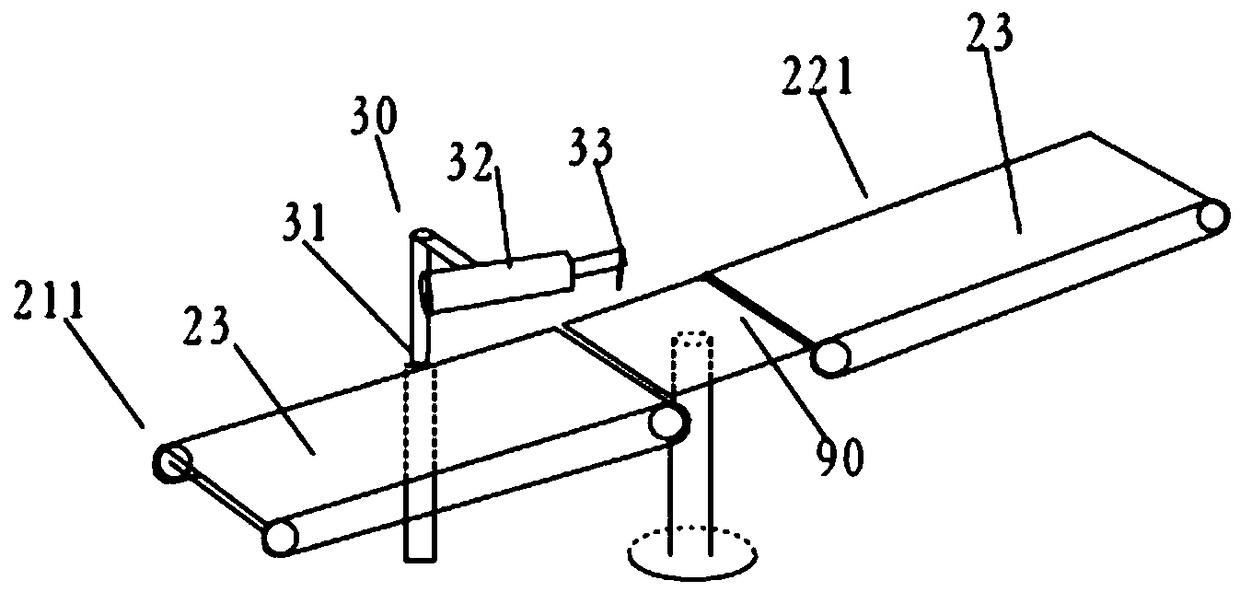

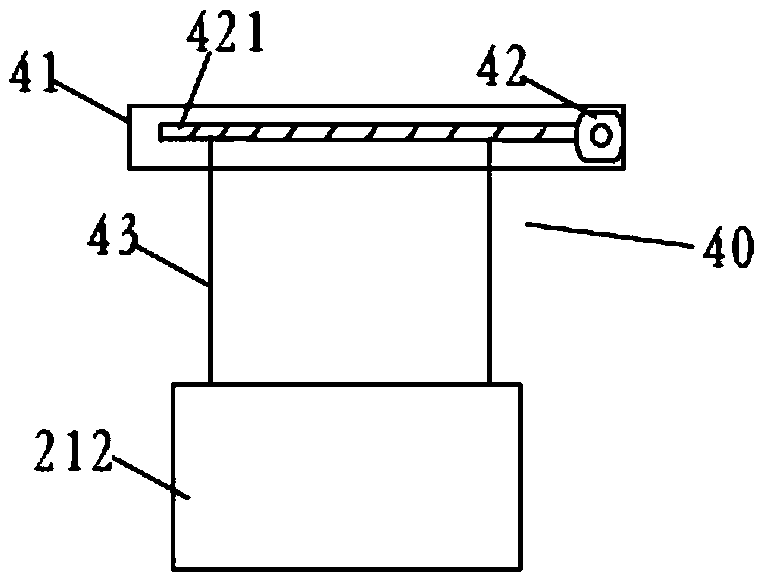

[0047] combine figure 2 As shown, there is a conveying mechanism for the detected object inside the rectangular lead chamber 10 , which includes a feed window 21 , a discharge window 22 , a first conveying mechanism 211 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com