A Ka-band double-sided ferrite thin film microstrip line circulator

A technology of ferrite film and microstrip line, which is applied in waveguide devices, electrical components, circuits, etc., can solve the problems of film performance degradation, film breakage, and restricting the development of thin film devices, so as to meet the requirements of reducing thickness and avoid easy Effects of cracking, improved looping and working bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions provided by the present invention will be further described below in conjunction with the accompanying drawings.

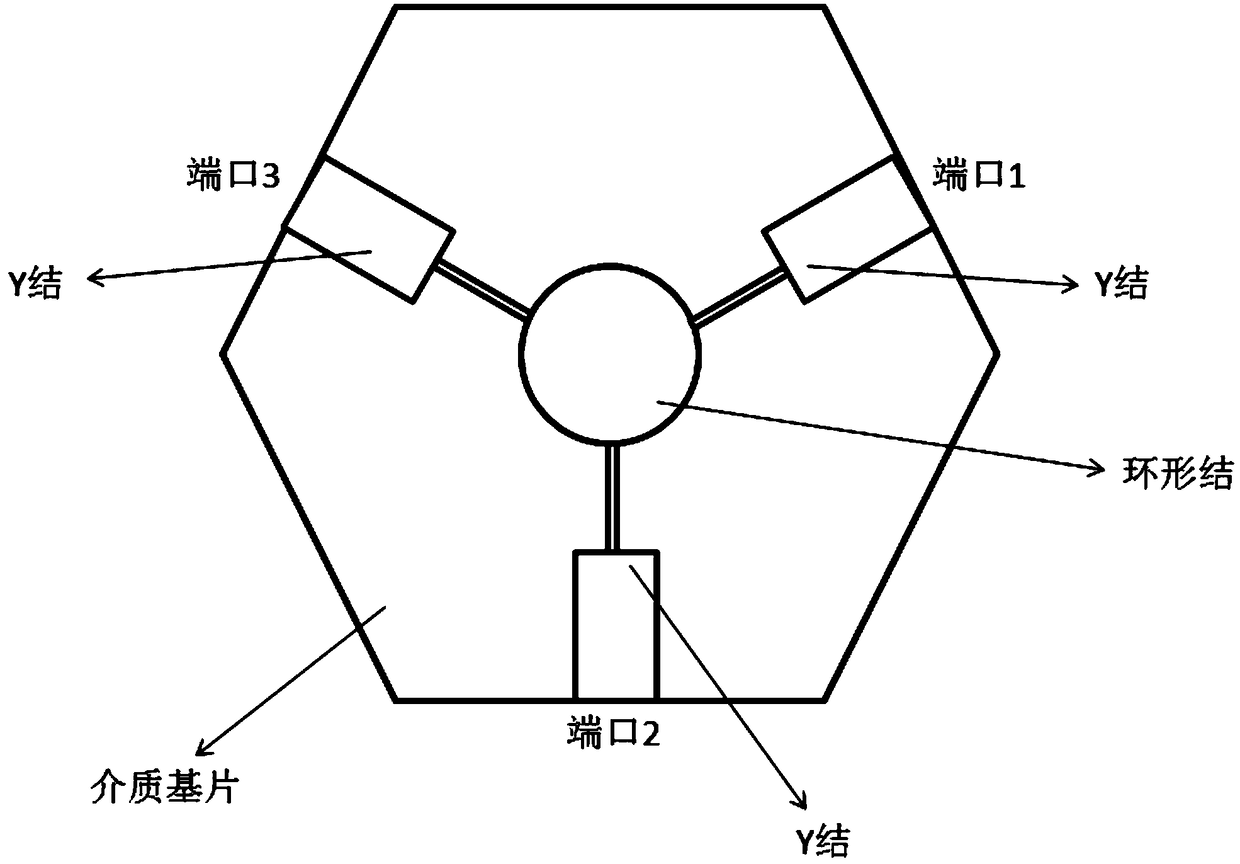

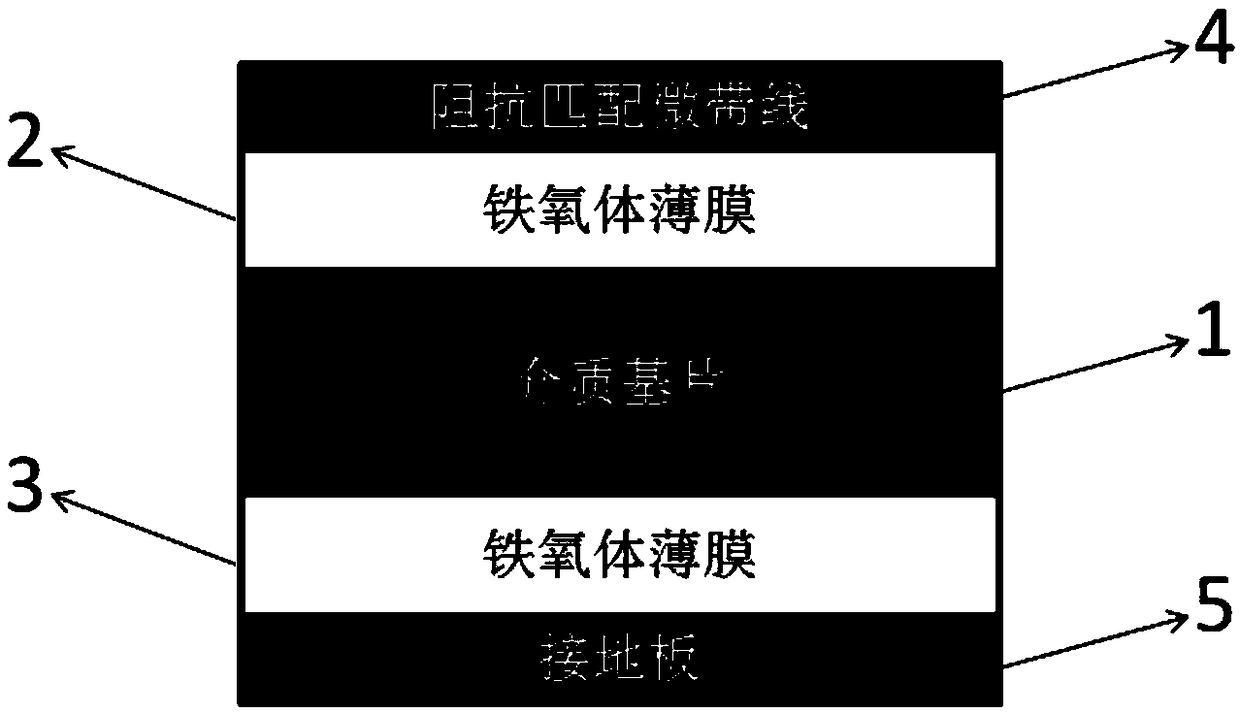

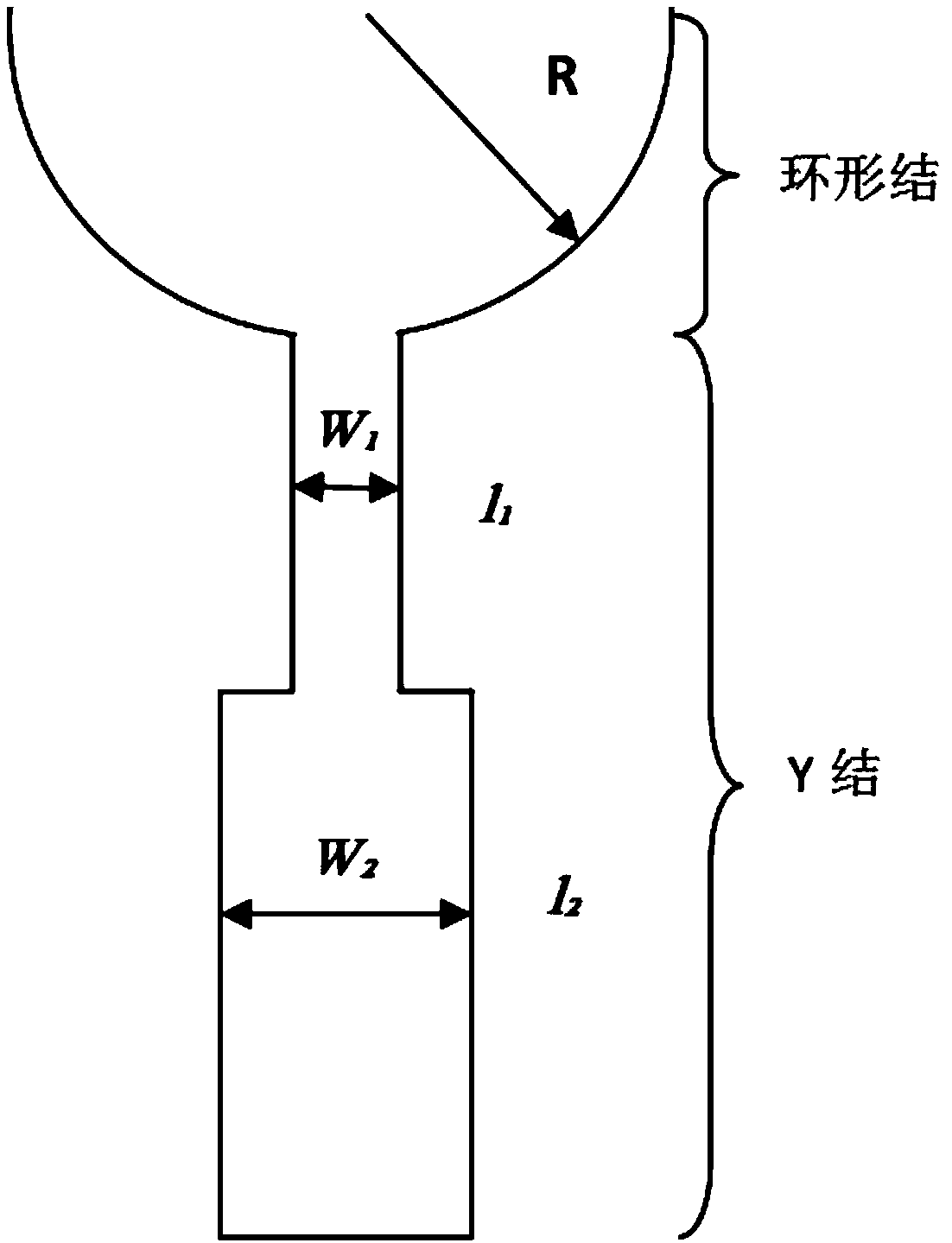

[0026] see figure 1 , which is a top view of the Ka-band laminated thin-film ferrite microstrip line circulator of the present invention, which is a three-terminal device, and three ports form a circular input and output. see figure 2 , shown is a cross-sectional view of the Ka-band laminated thin-film ferrite microstrip line circulator of the present invention, comprising a dielectric substrate 1, forming a first ferrite thin film layer 2 and a second ferrite thin film layer 2 sequentially on the dielectric substrate by a coating process The second ferrite film layer 3 and the microstrip line 4 arranged on the second ferrite film layer, the microstrip line 4 is used as the conductor circuit of the circulator to connect with the external circuit and the grounding plate 5 . The planar shape of the crystal dielectric substrate, ferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com