Metal-insulator-metal capacitor and method for forming same

A technology of insulators and capacitors, applied in capacitors, circuits, electrical components, etc., can solve problems such as poor performance of MIM capacitors, achieve the effect of reducing the thickness and increasing the capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It can be seen from the background art that the metal-oxide-metal (MIM: Metal-insulator-Metal) capacitor formed in the prior art has poor performance.

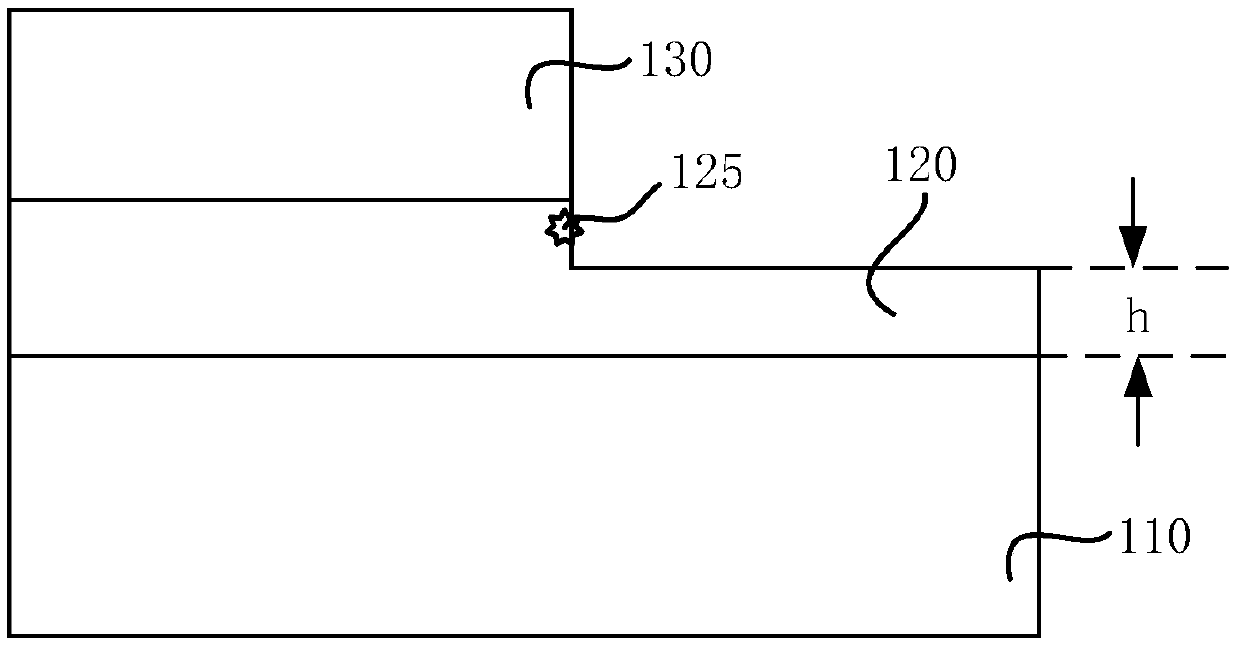

[0029] The inventor of the present invention has studied the technology that prior art forms MIM capacitance and finds, as figure 1 As shown, in the prior art, when forming the upper electrode 130 of the MIM capacitor, over-etching is performed to reduce the thickness h of the dielectric layer 120 on the lower electrode 110 . The greater the thickness h of the dielectric layer 120 is, the greater the thickness of the photoresist required for subsequent etching of the lower electrode 110 is, and the etching difficulty increases. However, the more the dielectric layer 120 is etched, the larger the exposed sidewall area of the dielectric layer 120 under the upper electrode 130 is, and etching damage 125 is easily formed on the sidewall during the etching process, resulting in MIM. The time-dependent dielectric breakdown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com