A metal motor house structure of automobile

A technology of outer casing and outer casing, which is applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of easy rusting of the casing, reduced service life of the outer casing, cracking, etc. Longer service life and better heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

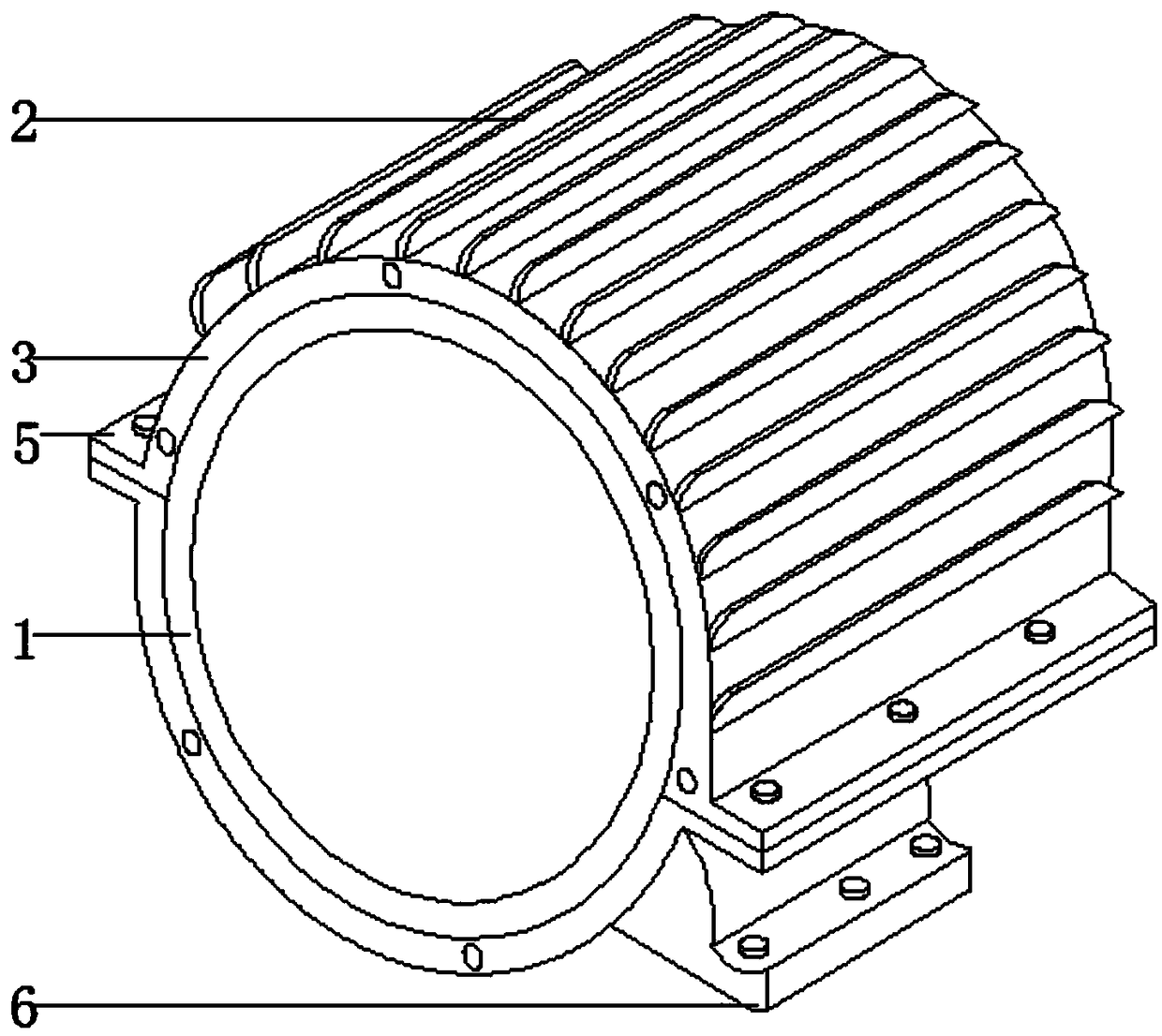

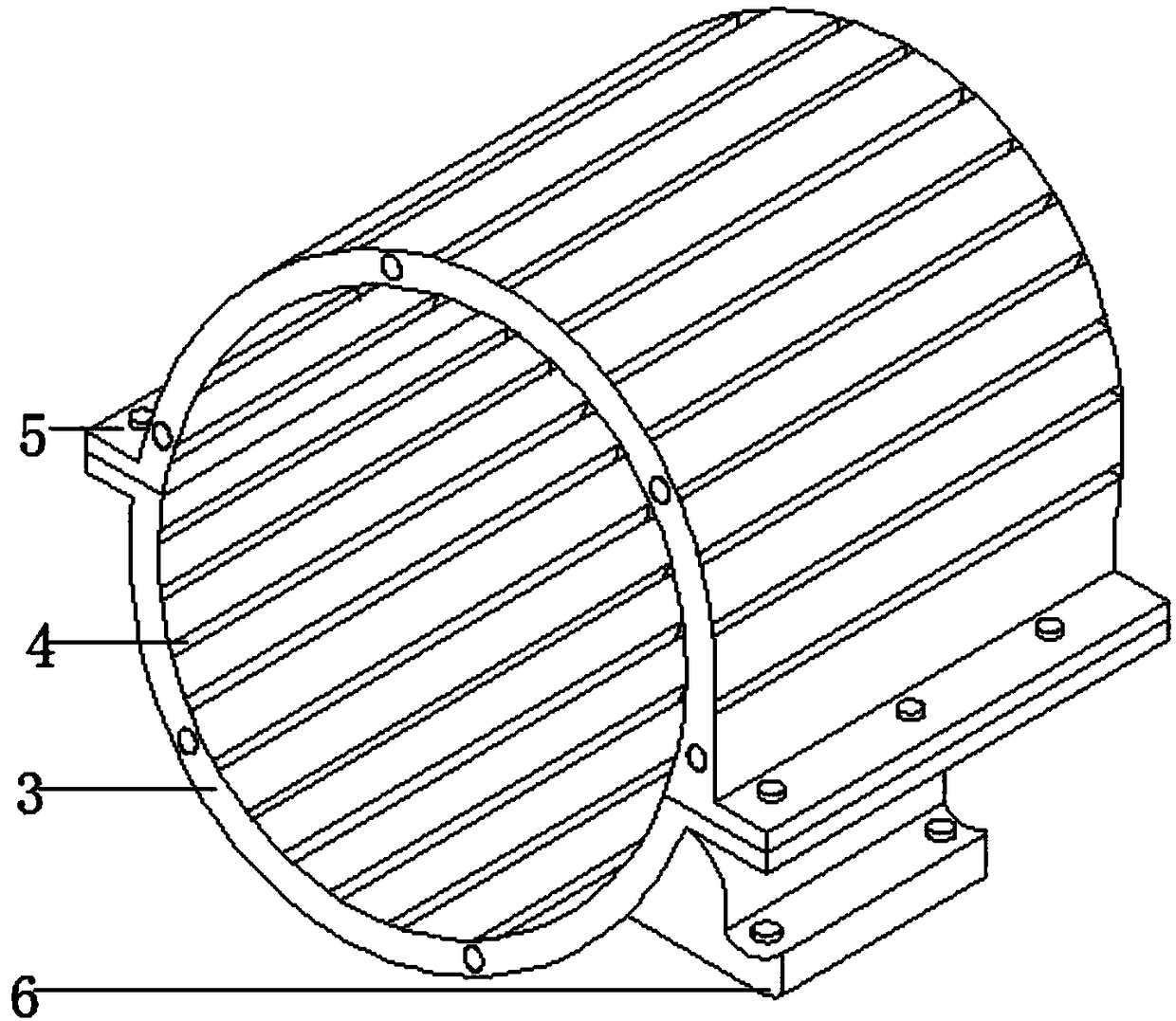

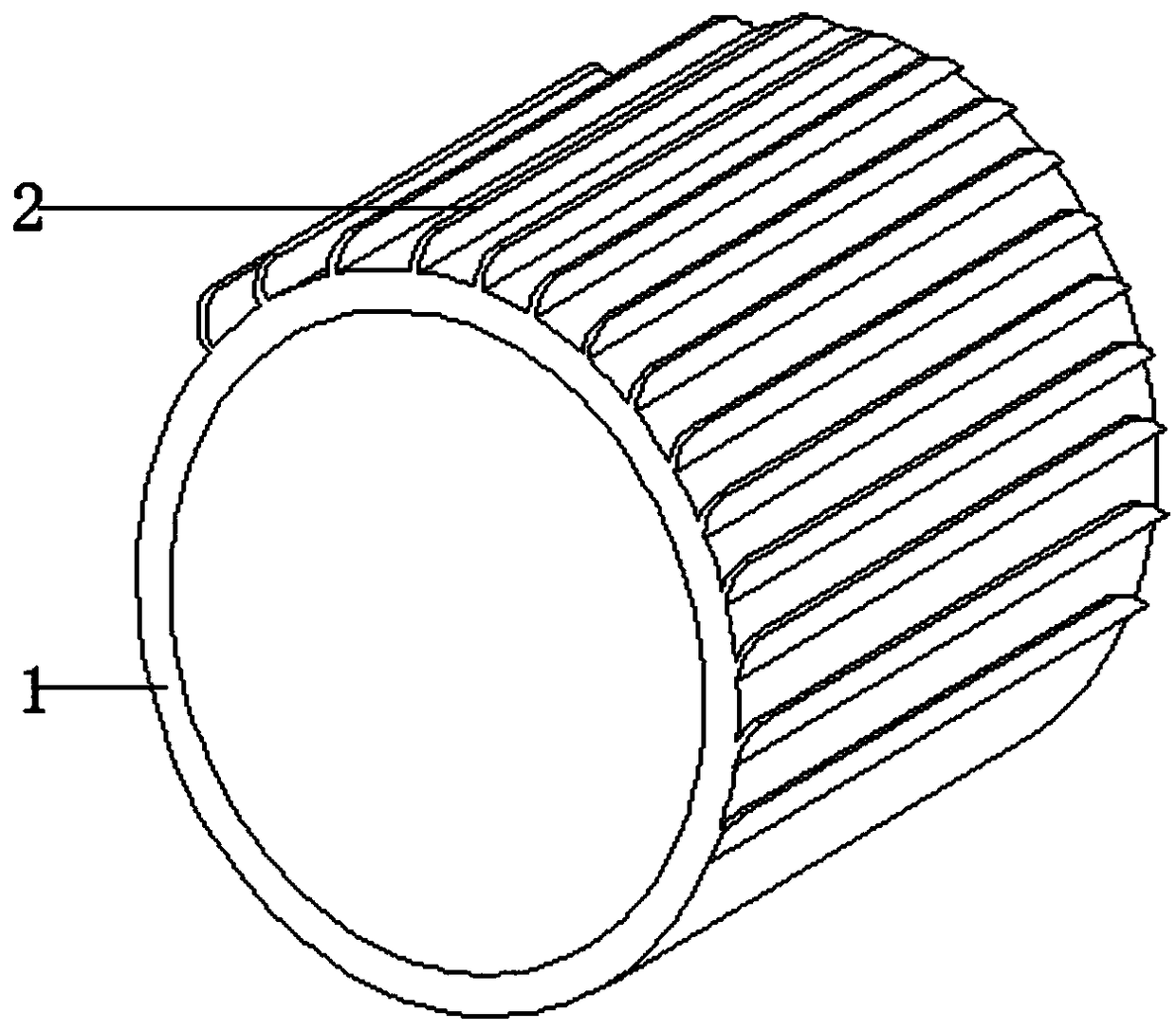

[0025] An automobile metal motor outer shell structure, comprising: an inner shell 1, a heat sink 2, an outer shell 3, a card slot 4, a connecting plate 5, and a fixing seat 6; the heat sink 2 is arranged on the top of the inner shell 1, and the heat sink 2 and the The inner shell 1 is an integrated structure; the outer shell 3 is arranged outside the inner shell 1, and the outer shell 3 and the inner shell 1 are connected by fitting; the card slot 4 is arranged inside the outer shell 3, and the card slot 4 and the outer shell 3 are One-piece structure; the connecting plate 5 is arranged on both sides of the shell 3, and the connecting plate 5 and the shell 3 are integrally structured; the fixing seat 6 is arranged on both sides of the bottom of the shell 3, and the fixing seat 6 and the shell 3 are connected by welding connect.

[0026] Specifically, the inner shell 1 is a circular cylindrical structure made of aluminum, and the upper part of the inner shell 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com